Event

Debug Embedded Systems with Your Oscilloscope

PO Box 24058

Federal Way, WA 98093

United States

Date: Thur, Mar. 18, 2021

Time: 11AM Pacific | 2PM Eastern

Duration: 1 hour

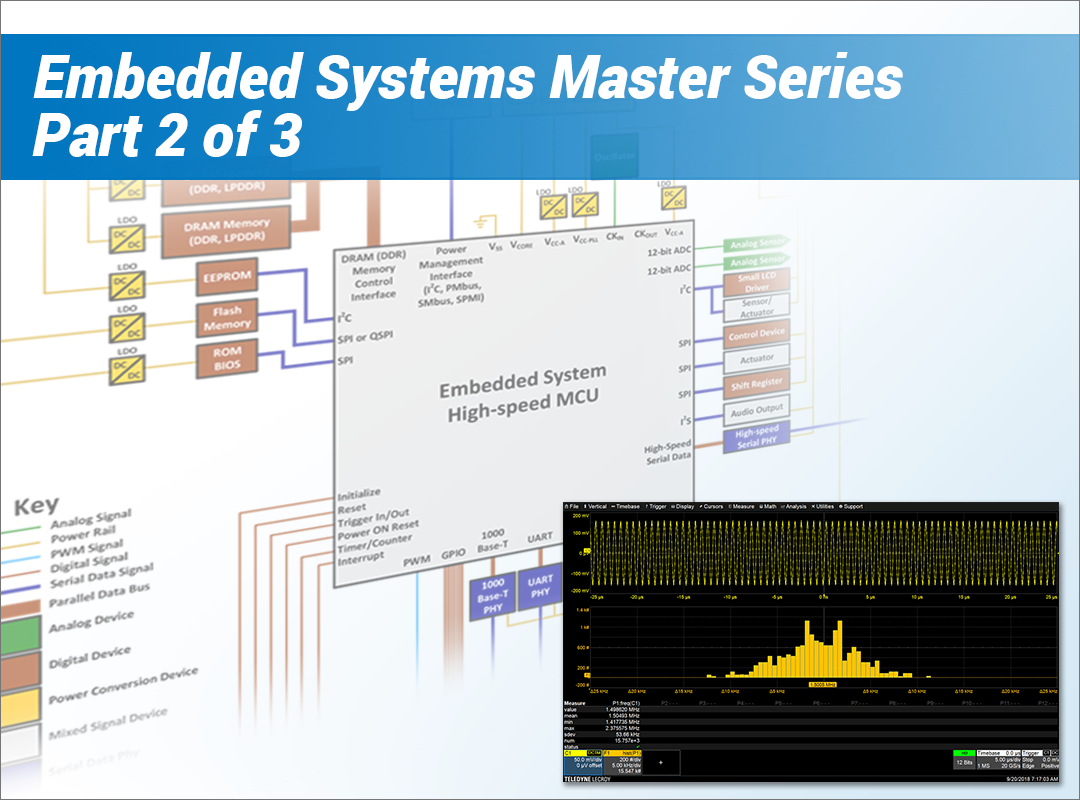

How to Efficiently Debug Embedded Systems with Your Oscilloscope

Join Teledyne LeCroy for this 3-part webinar series on how to efficiently and accurately debug embedded systems with your oscilloscope. The goal of this series is to improve your knowledge and efficiency in validating and troubleshooting the interactions of analog, digital, serial data, and sensor signals in embedded designs.

Fundamentals of Advanced Measurements and Math

In this session (Part 2), we will develop skills for acquiring and performing measurements, waveform math, and analysis that isolate and help us locate amplitude and timing errors within an embedded design.

Topics to be included:

- Plotting measurement values over time

- Waveform math tools

- Measurement parameter Tracks and Trends

- Serial data triggering and decode

- Mixed signal digital capture and integration

Who should attend? Design Engineers and Technicians looking to improve skills and efficiency in using an oscilloscope to both validate and troubleshoot the circuit performance of embedded designs.

What attendees will learn? How to use underutilized oscilloscope math and measurement tools that have broad utility in embedded system validation and debug.

Presenter: Stephen Murphy, Marketing Product Specialist / Applications Engineer

Can't attend live? Register anyway, and we will send you the recording and slides afterward.

Want to watch previous sessions?

Part One: Fundamentals of Signal Display and Measurements

Register for the rest of the series:

Part Three: 4 Practical Real-world Examples of Embedded System Validation and Debug