Event

How to Characterize Lossy Interconnects in High-speed Designs

PO Box 24058

Federal Way, WA 98093

United States

Date: Wed, Mar. 17, 2021

Time: 11AM Pacific | 2PM Eastern

Duration: 1 hour

How to Characterize Lossy Interconnects in High-speed Designs

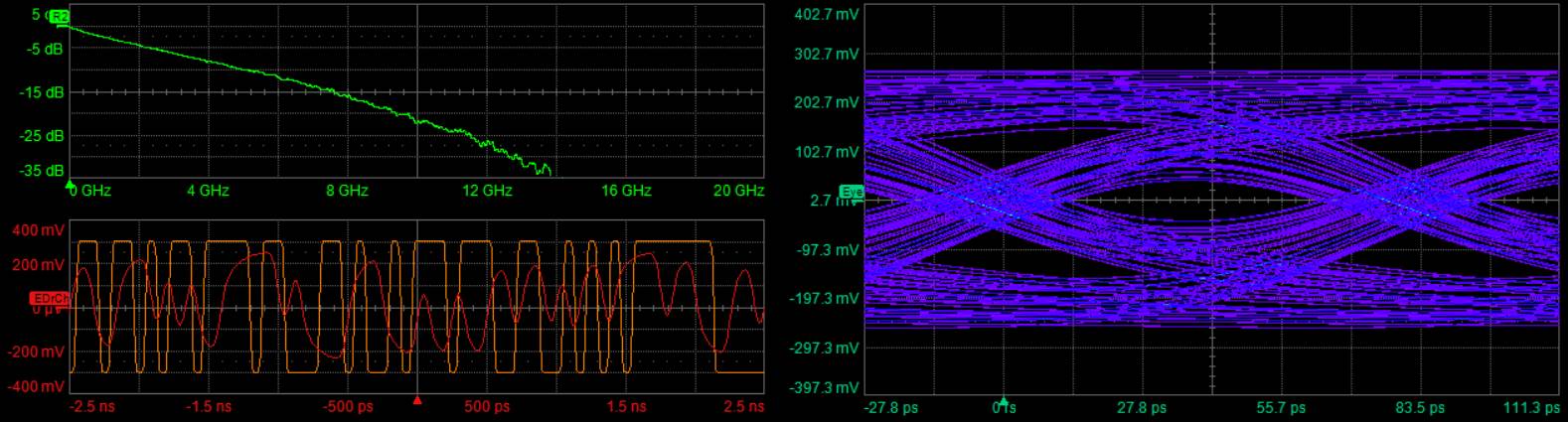

Join Eric Bogatin and Teledyne LeCroy for this webinar exploring the properties of lossy transmission lines and how to extract their important figures of merit. All losses are frequency dependent. We introduce a simple way of estimating the losses expected based on the interconnect design and how to measure the losses using S-parameters.

Topics to be included:

- The root cause of losses

- Estimating the conductor and dielectric losses

- Extracting an important figure of merit from insertion loss

- How much insertion loss is too much?

- Estimating the maximum data rate of a channel from the insertion loss

Who should attend? Any Engineer designing, validating or using high-speed serial data links.

What attendees will learn? How to analyze insertion loss and interpret measurements in terms of highest acceptable data rate.

Presenter: Dr. Eric Bogatin, Teledyne LeCroy Fellow

Can't attend live? Register anyway, and we will send you the recording and slides afterward.

You may also be interested in: