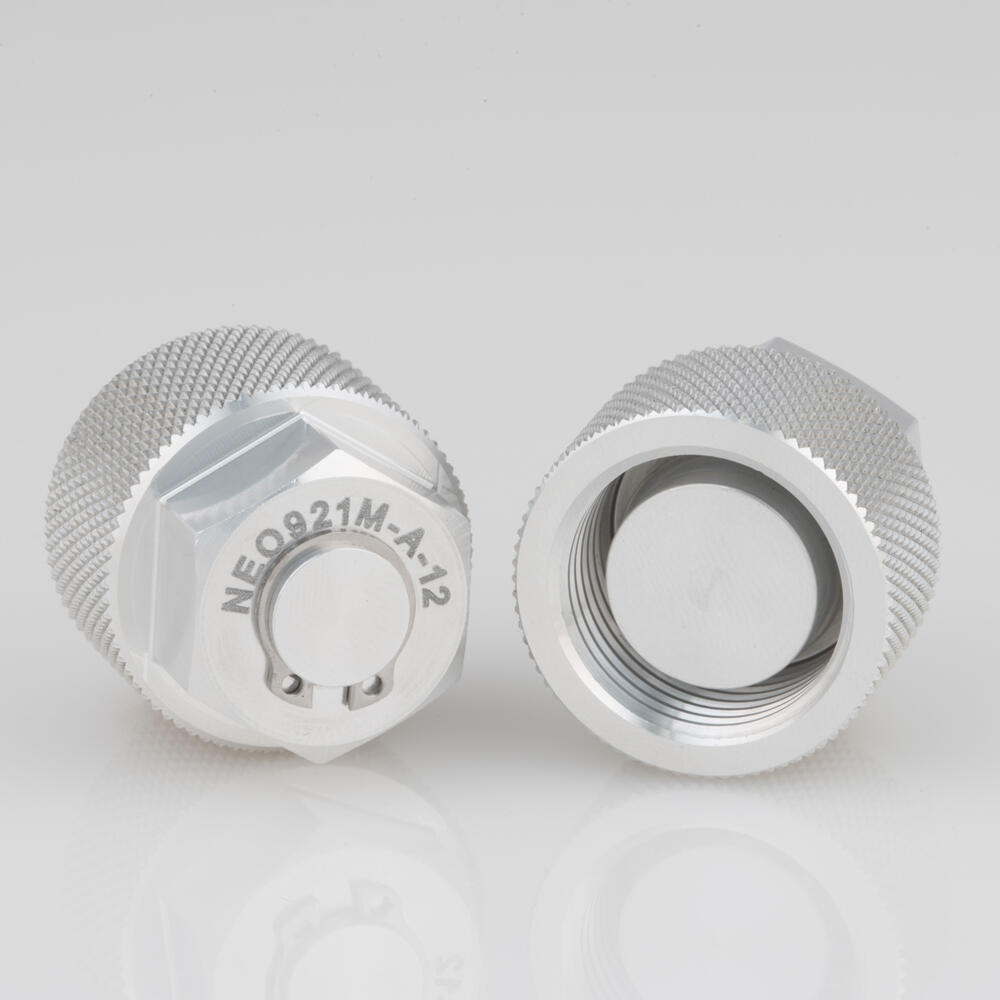

Dualos - Low Cost Hydraulic Caps

Parts in compliance with all SMOT document requirements.

|

Part Number |

Port Size |

Thread End |

|

NEO 921M-A-04 |

4 |

0.4375-20 UNJF Class 3B |

|

NEO 921M-A-05 |

5 |

0.5000-20 UNJF Class 3B |

| NEO 921M-A-06 |

6 |

0.5625-18 UNJF Class 3B |

|

NEO 921M-A-08 |

8 |

0.7500-16 UNJF Class 3B |

| NEO 921M-A-10 |

10 |

0.8750-14 UNJF Class 3B |

|

NEO 921M-A-12 |

12 |

1.0625-12 UNJ Class 3B |

|

NEO 921M-A-16 |

16 |

1.3125-12 UNJ Class 3B |

|

NEO 921M-A-20 |

20 |

1.6250-12 UNJ Class 3B |

*Approximate Dimensions [inches]

|

Part Number |

Port Size |

Thread End |

|

NEO 925M-A-04 |

4 |

0.4375-28 UNJEF Class 3B |

|

NEO 925M-A-06 |

6 |

0.5625-24 UNJEF Class 3B |

| NEO 925M-A-08 |

8 |

0.7500-20 UNJEF Class 3B |

|

NEO 925M-A-10 |

10 |

0.8750-20 UNJEF Class 3B |

| NEO 925M-A-12 |

12 |

1.0625-18 UNJEF Class 3B |

|

NEO 925M-A-16 |

16 |

1.3125-16 UNJ Class 3B |

|

NEO 925M-A-20 |

20 |

1.6250-16 UNJ Class 3B |

*Approximate Dimensions [inches]

More Product Information

-

Versatile 9.2 megapixel camera

-

10.1 fps at full resolution

-

Power over Ethernet option

-

Video-iris lens control

-

Monochrome (G-917B) and color (G-917C) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba SDK and compatibility to the most popular third party image-processing libraries.

- High Power Density: 600 watts in 1U (1.75 inches) high, half rack (8.5 inches) wide; no top or bottom clearance spacing required.

- Near Linear Ripple & Noise Ripple as low as 2.5mV rms, noise as low as 15mV p-p.

- Remote Control

- LXI Compliant Ethernet LAN / RS-232C (16 bit)

- IEEE-488.2 / RS-232C (12 bit)

- Standard analog programming 0-5V, 0-10V, or 0-5kΩ.

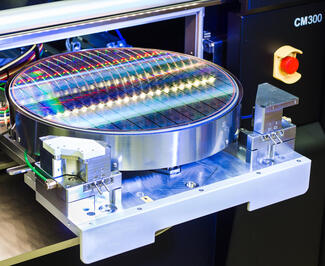

Flexibility

- Application flexibility: Coax, Triax, RF/mmW, High Power, Double Sided

- Temperatures range from -60°C to +300°C

- Surfaces are nickel or gold-plated

- Hybrid chuck design – operation with and without cooling unit

- Field-upgradeable: On-site cold upgrades for all main prober platforms

Highest Efficiency for Reduced Cost of Test

- Up to 25% lower air consumption (CDA) than other systems on the market with no compromise in transition times

- Up to 15% faster transition times than other systems on the market

X-LITE (EWC27) has been designed with for small satellites flying in Low Earth Orbit. One of the main challenges is low consumption of radio communication links. X-LITE (EWC27) offers high data rate telemetry and robust X band transmission.

With the powerful modular LUMIMAX® LED Bar Lights test areas can be uniformly illuminated even from distances of more than 1 meter. The Bar Lights with integrated controller technology are available in different configurations for incident and backlight applications.

The modular bar lights expand the portfolio and include now bar lights of up to 4 meters for even larger test areas. Thanks to the modular concept, specific sizes can be realized quickly and without additional development costs. You can select standard versions using our product configurator. Please contact our sales team for special enquiries about customised lengths.

-

High SNR mode (up to 24 dB better signal-to-noise ratio)

-

Low-noise binning mode

-

Shading correction

-

Defect pixel correction

-

Area of interest (AOI), separate AOI for auto features

-

Binning

-

Decimation

-

Auto gain (manual gain control: 0 to 24.4 dB)

-

Auto exposure (39 µs to 67 s)

-

Auto white balance

-

Look-up table (LUT)

-

Hue, saturation

-

Color correction

-

Local color anti-aliasing

-

Reverse X/Y

-

Deferred image transport

-

Trigger programmable, level, single, bulk, programmable delay

-

Sequence mode (changes the camera settings on the fly)

-

SIS (secure image signature, time stamp for trigger, frame count etc.)

-

Storable user sets

-

Camera and IEEE 1394b cable (other configurations on request)

-

Type APS-H CMOS sensor

-

IEEE 1588 PTP

-

Power over Ethernet

-

4.59 fps at full resolution

-

Extended near-infrared (GT5120NIR) model

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Enhanced Defect Pixel Correction feature with a new Defective Pixel List Manager tool that allows you to load different user defined defective pixel lists to match your application and optimize the life cycle of the camera

-

Monochrome (G-040B) and color (G-040C) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

Dualos

787 SMOT compliant caps and plugs for hydraulic, fuel or DI water lines. 3000 PSI & 5000 PSI fine and extra fine threaded aircraft to JIC adaptors