Focus Microwaves - Auriga Standard PIV 220V & 600V

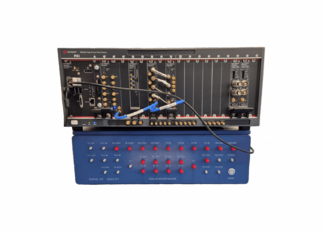

Auriga’s 5th generation pulsed IV/RF characterization system delivers unparalleled performance, capturing measurements with incredible speed and accuracy. Pulsed IV (current-voltage) measurements have emerged as the preferred method of capturing current-voltage characteristics of active devices such as field effect (FETs) and bipolar junction (BJTs) transistors.

Introducing Auriga’s 5th generation pulsed IV/RF characterization system delivers unparalleled performance, capturing measurements with incredible speed and accuracy. Pulsed IV (current-voltage) measurements have emerged as the preferred method of capturing current-voltage characteristics of active devices such as field effect (FETs) and bipolar junction (BJTs) transistors. With the growing popularity of higher-power devices, like GaN HEMTs, LDMOS, SiC, and graphene, current and voltage requirements are constantly being pushed higher and higher.

Auriga MEM™, Auriga’s newest pulsed IV function, enhances current resolution to an industry-leading 0.01% of maximum current. Using Auriga’s advanced calibration algorithms and an external Keysight digital multimeter (DMM), Auriga MEM brings the DC measurement plane directly to the device under test.

220 V

Auriga PIV System – 220 V Configuration

600 V

Auriga PIV System – 600 V Configuration

Bipolar Pulser

More Product Information

-

High spatial resolution

-

IEEE 1588 PTP

-

Power over Ethernet

-

Defect pixel masking

-

Monochrome (GT4400) and color (GT4400C) models

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-5e or CAT-6)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Defect pixel masking feature with the Defect Mask Loader tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

Focus Microwaves' bi-directional couplers, available in 40, 67, 110 and 120 GHz models, offer high directivity and low insertion loss. These couplers provide precise measurements, making them ideal for advanced RF and microwave testing, ensuring accuracy and efficiency in both R&D and production environments.

-

Type APS-H CMOS sensor

-

IEEE 1588 PTP

-

Power over Ethernet

-

4.59 fps at full resolution

-

Monochrome (GT5120) model

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Enhanced Defect Pixel Correction feature with a new Defective Pixel List Manager tool that allows you to load different user defined defective pixel lists to match your application and optimize the life cycle of the camera

-

High spatial resolution

-

IEEE 1588 PTP

-

Power over Ethernet

-

Defect pixel masking

-

Monochrome (GT5400) and color (GT5400C) models

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Defect pixel masking feature with the Defect Mask Loader tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

Unlock precise nonlinear transistor behavior representation with our Cardiff Model portfolio. Improve accuracy across a wide impedance space effortlessly.

Focus Microwaves introduces a cutting-edge noise measurement system comprising three integral components: the Input Noise Module (INM), Output Noise Module (ONM), and Noise Module Controller (NMC). This system extracts precise noise parameters, offering rapid, stable measurements and optimized performance with dedicated software for calibration and analysis.

-

Type APS-H CMOS sensor

-

IEEE 1588 PTP

-

Power over Ethernet

-

4.59 fps at full resolution

-

Extended near-infrared (GT5120NIR) model

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Enhanced Defect Pixel Correction feature with a new Defective Pixel List Manager tool that allows you to load different user defined defective pixel lists to match your application and optimize the life cycle of the camera

Focus Microwaves’ RAPID DT, built on Keysight’s M5000 PXI modules, delivers fast, broadband load pull and S-parameter testing up to 18 GHz. It supports CW and pulsed signals across wide bandwidths, making it ideal for advanced standards like 4096QAM 802.11be.

Discover Focus Microwaves' wideband fundamental tuners. The C-Series (Computer-Controlled Microwave Tuners) feature one to three wideband probes, enabling exceptionally broad frequency coverage—ideal for high-power and wideband noise applications.

Designed for precision, the tuner's long-lasting RF probes ensure optimal tuning accuracy while eliminating spurious resonances. The integration of multiple probes within a single tuner provides ultra-wideband coverage, making it a versatile solution for demanding RF applications.

Focus Microwaves

Focus Microwaves is a pioneering engineering company, built around the innovations of its founder Dr. Christos Tsironis who developed his first manual tuner in 1973 and is the inventor of most existing electro-mechanical tuner families. The success of Focus is based on the engineering and manufacturing skills of its highly motivated and experienced team of engineers and technicians, who have been trained and encouraged to develop new technologies. In addition, listening to our customers needs and insights helps us discover and develop new and measurement methods on an ongoing basis, relentlessly pushing the limits of what is possible.

From humble beginnings in 1988, Focus has become the main supplier of advanced Load Pull and Noise Tuner Systems. Our mission is to provide effective, reliable and innovative solutions for non-50 Ohm testing (Noise and Load Pull) of RF microwave transistors, thus enabling our customers to compete in the marketplace with better designs and to advance the understanding and knowledge of the field.

Contact Details

Focus Microwaves Inc. Main Head Office

4555 Chem. du Bois-Franc, Saint-Laurent, QC H4S 1A8, Canada

Phone: +1-514-684-4554

Test & Measurement