Focus Microwaves - Noise Measurement System Up to 170 GHz

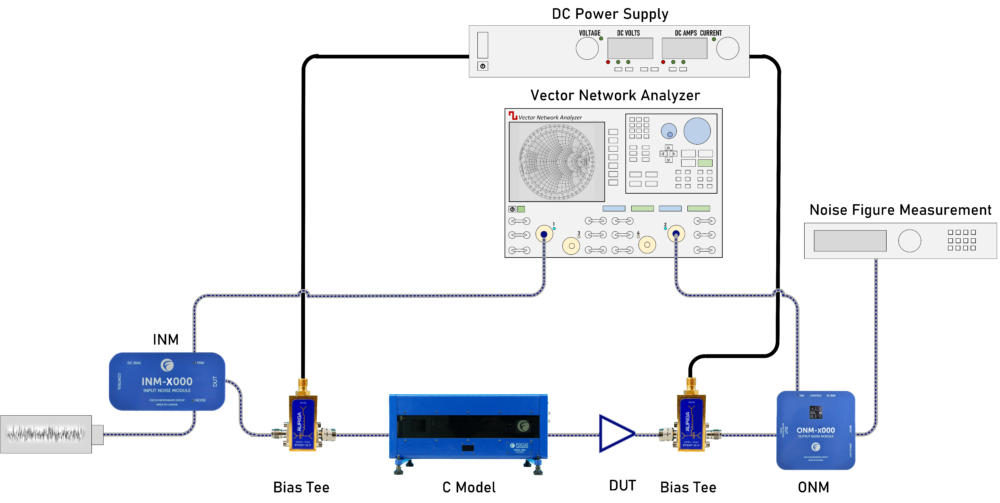

Focus Microwaves introduces a cutting-edge noise measurement system comprising three integral components: the Input Noise Module (INM), Output Noise Module (ONM), and Noise Module Controller (NMC). This system extracts precise noise parameters, offering rapid, stable measurements and optimized performance with dedicated software for calibration and analysis.

Focus Microwave’s wide-band Noise Measurement system is a cutting-edge solution that covers an expansive frequency range from 0.5 to 170 GHz, making it one of the industry’s most comprehensive noise measurement systems available. This system is designed to facilitate the accurate extraction of the four essential noise parameters of a device under test (DUT):

- Minimum Noise Figure (NFMIN): Represents the lowest achievable noise figure of the DUT.

- Equivalent Noise Resistance (RN): Refers to the equivalent noise resistance presented by the DUT.

- Optimum Noise Reflection Factor (Magnitude, Phase): Indicates the optimum noise reflection factor of the DUT in terms of magnitude and phase for optimal noise performance.

The noise measurement system caters to both connectorized and bare die devices, offering versatility in device compatibility. Furthermore, it provides fast, precise, and stable measurements crucial for accurate noise analysis within the specified frequency range.

The system comprises three key components:

- Input Noise Module (INM)

- Output Noise Module (ONM)

- Noise Module Controller (NMC)

These modules work in tandem to improve precision and sensitivity in noise receiver performance, simplify system calibration procedures, and enhance the DUT measurement process. The direct probe mounting of the source tuner and the utilization of the new Delta series noise modules set a new standard in the industry, elevating sensitivity, expanding the dynamic range, and ensuring comprehensive coverage across a broad frequency band.

Models & Specifications

Setup