MVG- Rotary Positioners - Polarization Positioners: Medium Duty

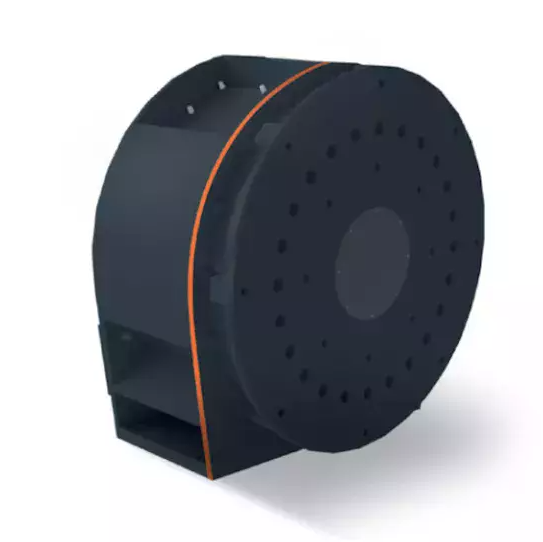

The MVG-Orbit/FR Legacy Series Polarization Positioners provide accurate, balanced rotation, and controllable velocity for the positioning of devices in test configurations. Their sturdy and straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio.Turntable diameters up to 30.0 in (762 mm) .

|

Key Features |

|---|

|

Broad Selection - 9 Models |

|

Operating Loads Ranging from 4,000 to 20,000 lbs (1,810 to 9,070 kg) |

|

Turntable Diameter Ranging from 20.3 to 30.0 in (516 to 762 mm) |

|

Excellent Angular Position Accuracy |

|

Low Backlash Design |

|

Precision Bearings |

|

Closed Loop Servo Control |

|

Industry-Standard Wiring |

|

Tachometers for Optimum Speed Regulation & Control |

|

Wide Operating Temperature Range: - 4° F to 140° F (- 20° C to 60° C) |

|

Fully Enclosed Design of Drive Gear Train & Data Take-Off |

|

Wide Variety of Available Options |

|

Applications |

|---|

|

General Purpose Positioning Subsystems |

|

Far-Field & Near-Field Antenna Measurements |

|

Indoor & Outdoor Use |

|

Industries |

|---|

|

Solutions for Academic & Research Institutes |

|

Solutions for Aerospace & Defense |

More Product Information

The AL-4164 and AL-4166 programmable controllers offer real-time control of positioning subsystems used in near-field and far-field antenna measurement systems. They may be configured to drive planar scanners and general purpose far-field positioners that are encoder-based or involve simultaneous motion.

AL-58000 model towers are suited for very heavy duty applications with an operating load of up to 17,600 lbs (8,000 kg). They have durable steel masts, which can be vertical or inclined (limited to specific loads). They are available with a steel linear offset slide that is manual hand-wheel style, manual fixed step, or motorized.

The Performance Series EL/AZ positioners represent the latest generation of multi-axis rotary positioning subsystems. They offer enhanced capabilities and improved performance relative to size, and incorporate new engineering advances.

These positioners provide accurate, balanced rotation, and controllable velocity. Their rugged yet straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio. Typically, the unit includes the body, precise slew bearings, DC motor, gear reducer, encoder/synchro, and limit switch assemblies. The AUT mounting surface is designed with a threaded mounting hole pattern for ease of use. A Safe/Operate switch is included to ensure safety.

- Boost performance by up to 3x over its precursor thanks to an Intel x6000 series embedded processor

- Capture high-resolution images at high speed through a choice of CMOS sensors from two to 16 Megapixels

- Deploy in dirty, humid, or harsh industrial environments by way of a compact IP67-rated design

- Communicate actions and results to other automation and enterprise equipment via real-time digital I/Os, and Ethernet (TCP/IP, CC-Link IE Field Basic, EtherNet/IP™2, Modbus® , PROFINET® , and native robot interfaces)

- Handle Human-Machine Interface (HMI) function by way of VGA and USB connectivity

- Simplify vision setup and upkeep via integrated lens focusing and illumination intensity control

- Synchronize to the manufacturing line through the support for incremental rotary encoders

- Solve machine vision applications efficiently with Aurora Design Assistant by constructing flowcharts instead of writing program code

- Maintain control and independence through the ability to code custom flowchart steps

- Tackle machine vision applications with utmost confidence using field-proven tools for analyzing, locating, classifying, measuring, reading, and verifying

- Leverage deep learning for visual inspection through image classification and segmentation tools

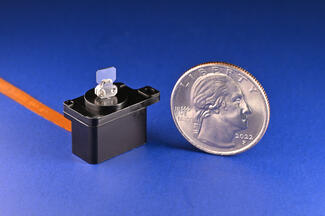

- Smallest rotary stage: 11.75 x 21.9 x 16 mm

- Embedded closed-loop controller

- No separate electronics needed

- 3.3 VDC input

- Accepts direct motion commands (I2C, SPI, or UART)

- Continuous 360° rotary motion

- Angular resolution ~21.9727 mdeg closed loop

- Built-in absolute position sensor

- Millisecond step and settle times

- 0.5 deg in 16 ms closed loop

- 0.5 deg in 1.2 ms open loop

- Holds position with zero power and no jitter

Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Use with liquid nitrogen or helium, depending on the target temperature. Or use of cryo-cooler for dry-cooling option.

- Accessories available, such as black bodies and optical motion analysis tools

- Optional upgrade for 300 mm wafer

- Designed for industrial environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

- Ideal for small structures

See "Specifications & Details" tab for more key features

The EH022 EMC Horn combines stable gain performance and low VSWR with wide band frequency operation. The horn is single linearly polarized with excellent cross-polar discrimination. The unique horn design suppresses any possible excitation of higher order modes in the aperture and maintains a well-defined smooth radiation pattern in the direction of the boresight axis throughout the operational bandwidth.

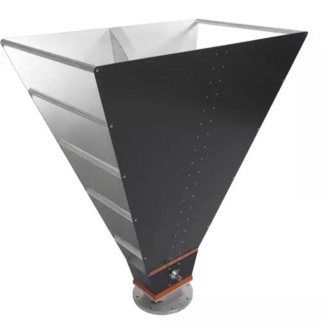

Pylons are stationary metal Device Under Test support structures designed to minimize measurement signal backscattering.

Their shapes, sizes, and construction specifications are determined by requirements such as maximum DUT size, its mechanical properties, and minimum rotator size.

Specific application to Automotive.

The Gold standard for EMC Anechoic Chambers, this 10 meter test range ensures EMC compliance testing Emission and Immunity testing and is compliant to ANSI C63.4/CISPR-16-1-4 with a Test Volume diameter of 4 meters or greater. The most versatile and accurate of EMC test chambers. Ferrite tiles and hybrid pyramidal absorbers allow for high accuracy and performance while meeting compact space requirements.

Microwave Vision Group (MVG)

Testing Connectivity for a Wireless World

The Microwave Vision Group offers cutting-edge technologies for the visualization of electromagnetic waves. With advanced test solutions for antenna characterization, radar signature evaluation and electromagnetic measurements, we support company R&D teams in their drive to innovate and boost product development.

Contact Details

Microwave Vision Group

1320 Air Wing Rd, Suite 101, San Diego, CA 92154, USA

Phone: 678-797-9172

Test & Measurement