NoiseKen - Thin Plate Broadband Antenna

-

A wide frequency range eliminating the need for antenna changes

-

30W maximum power input allows high filed strengths

-

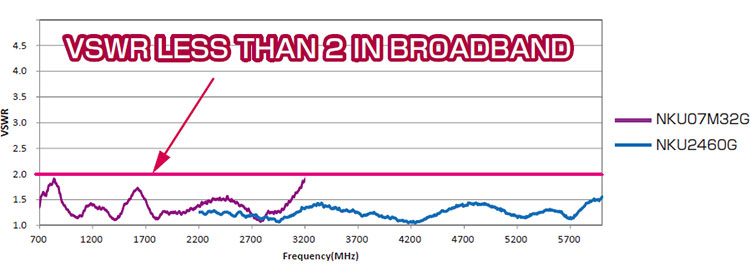

High efficiency due to a low VSWR and high gain

-

Suitable for broadband digital modulation thanks to a good VSWR flatness

-

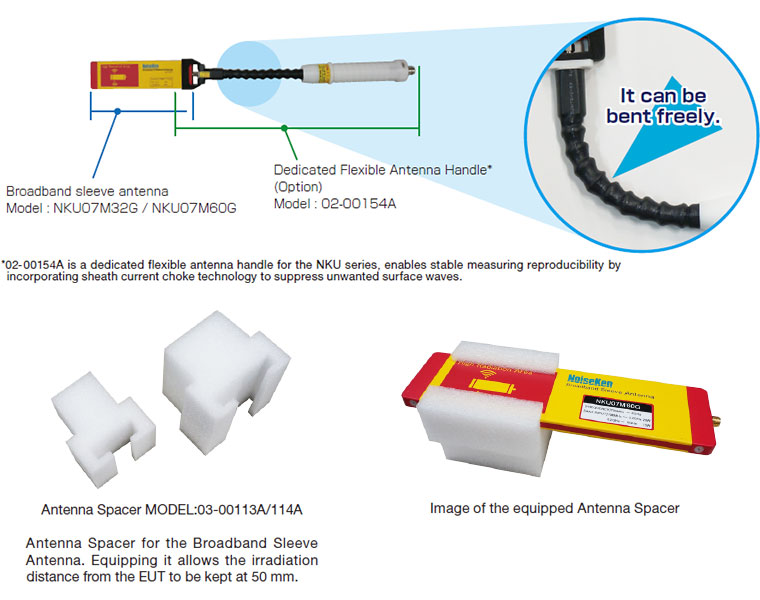

Small, light-weight and flat antenna easy to use in narrow spaces

-

Easy handling with a flexible arm

-

A wide radiation pattern makes directivity of the fields no longer an issue

|

Model |

NKU07M32G |

NKU2460G |

|---|---|---|

|

Frequency Range |

(660) 700 MHz ~ 3.2 GHz |

2.4 GHz ~ 6 GHz |

|

VSWR |

≦ 2 |

|

|

Maximum Power Input |

20 W (continuous) 30 W (continuous 10 minutes) |

10 W (CW) |

|

Input Impedance |

50 Ω |

|

|

Connector |

SMA(J) |

|

|

Dimensions |

W50mm × D8mm × H186 mm (protrusions excluded) |

W35mm × D10mm × H108 mm (protrusions excluded) |

|

Weight |

73.5g |

20 g |

VSWR

Antenna and Dedicated Flexible Antenna Handle

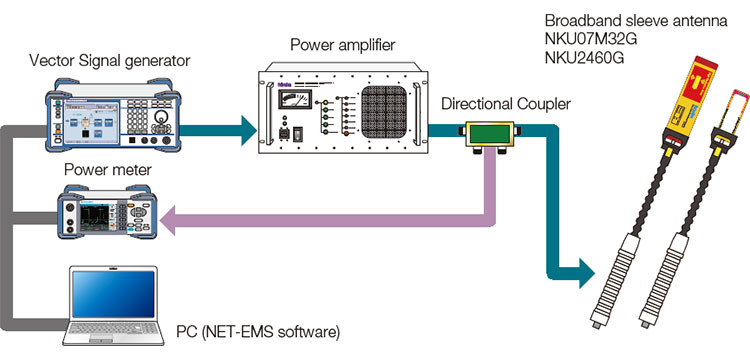

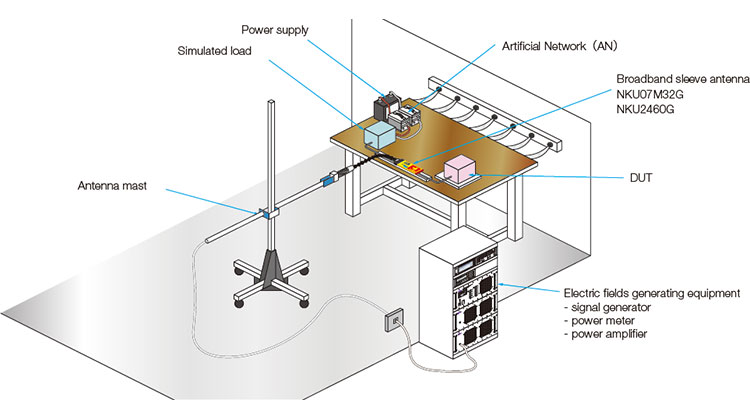

SYSTEM CONFIGURATION EXAMPLE

APPLICATION

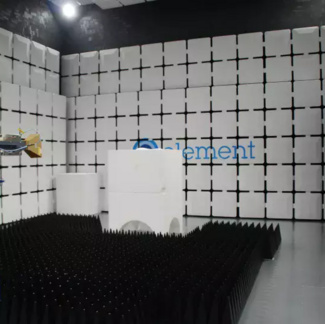

In-vehicle testing (ISO 11451-3 Ed.4: On-board transmitter)

Testing for automotive electronics (ISO 11452-9 Ed.2: Portable transmitter)

More Product Information

NoiseKen

For over 40 years from its foundation in 1975, Noise Laboratory has been focusing on immunity test equipment and related solutions.

Now their product lines include various types of immunity test equipment ranging from those conforming to IEC 61000-4 series standards, other international or national immunity standards and even to customer's in-house test standards.

Contact Details

Shinyei Corporation of America Head Office - Sole Authorized distributor of NoiseKen products