Products

Displaying 1 - 12 of 399

With the complexity of modern aerospace systems and components, stringent safety standards, and rapidly emerging trends and technologies, the aerospace and defense industry is facing a time of expeditious change. These industry trends shape aerospace manufacturers’ testing needs, growth objectives, and overall business goals. The reality is that aging aerospace facilities aren’t prepared to keep up with these rapid trends. Organizations seeking a competitive edge in the industry aim to achieve sustainable practices and regulatory compliance or explore new avenues in electric Vertical Take-Off and Landing (eVTOL) aircraft and space exploration.

The automotive industry is a sector frequently on the cusp of transformation. Fast-paced industry shifts span technology innovations, regulatory standards, green initiatives, and customer expectations, influencing manufacturers’ testing needs, growth objectives, and overall business strategies. Companies striving for a competitive edge focus on sustainable practices, regulatory compliance, and innovation in Electric Vehicles (EVs), alternative fuels, and autonomous driving systems.

The energy industry is primed for a wave of monumental change. The transition to renewable and alternative energy sources, advancements in energy storage, the rise of smart grids, and the electrification of transportation are driving significant changes domestically and globally.

Food and beverage technology is changing the global food and beverage industry from production to delivery. Consumer and market demand for sustainable and healthy products also means stricter regulations that promote safe consumption, sustainable package production, and effective recycling or disposal. These trends add up to a heightened demand for organizations in the industry to commit to testing protocols that ensure food safety, quality, and compliance with evolving standards. Facilities and manufacturers face challenges such as implementing advanced traceability systems, ensuring the safety and efficacy of new ingredients and packaging materials, and adhering to rigorous environmental regulations.

The laboratory and research industry faces unique challenges including long-standing, legacy pain points and frequently evolving needs. These include paramount safety and regulatory requirements for lab workers and patients alike, the need for high containment and sterility, and the integration of cutting-edge technologies. Complex and sensitive facilities require specialized testing solutions to ensure compliance, safety, and reliability. Effective planning and laboratory design and construction are crucial to creating environments that support advanced research and manufacturing processes, especially in the pharmaceutical and medical device sectors.

The industrial manufacturing industry has been a sector of constant innovation for centuries, continuously leveraging the data from frequent iterations to achieve new solutions. This is no different today, driven by advancements in automation, the adoption of Industry 4.0 technologies, the integration of IoT, and the shift towards sustainable manufacturing practices. These trends require the development of new testing protocols, thorough safety standards, and sophisticated quality control measures to ensure the reliability and efficiency of increasingly complex systems.

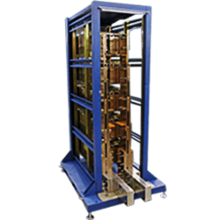

Power Subsystem for Transportable Military test stand

Provides eight channels of programmable DC power with output isolation function

Output disconnect function

Total control via Ethernet within power supply

Mounted in custom in transportable shock-mount case

When a catalog product cannot completely satisfy a requirement, AMETEK Programmable Power's Solutions Business provides custom power supply systems and integrations. The solutions range from OEM integration for medical and semiconductor industries to modular avionics ATE power subsystems to turnkey solar array simulators for satellites. We also can modify power supplies to meet your application requirements.

Complete solution - battery test, simulation & solar array simulator software included

Highest power density up to 37 kW in 4U rack height (9.25 kW/U)

Fastest and cleanest power available (fastest transient response and low output ripple and noise)

Universal 3-Phase AC Input accepts 180 VAC to 528 VAC

Longest manufacturer-based reliability guarantee: 5-year warranty

Parallel system power up to 1.2 MW

Output voltage up to 2,000 V

Bidirectional output current up to ±150 A, up to ±4,800 A in parallel

True extended wide-range autoranging output

Regenerative to 95%

Color touch panel user interface

OEM 6 channel DC source

Single Package 6-Pack of 600W power supplies

Complete self-contained controller operates independently once pre-set

Capable of ramps and sequences

Capable of inter-channel dependent operation

DeviceNet Interface

Solid State polarity switching

Provides 15,000A DC at 5V DC in current mode

Single complete package

Integrated bus bars

Current mode Analog programming

Input 400VAC, 220A/ph, Delta

Total power subsystem integration

Total power subsystem integration

Power sequencing

Elapsed time indication

EMO function

Custom rear output panel