-

Our High Intensity Linear Backlights offer 510 kLux output, perfect for back-lit, line-scanning applications.

-

Available in pre-engineered sizes from 6” (152mm) to 96” (2438mm) in 6″ increments.

-

A 3″ (75mm) length option is also available. Available intensity control provides illuminance adjustability for every 6″ increment via a 0 – 10v input

AMETEK - Engineered Systems

When a catalog product cannot completely satisfy a requirement, AMETEK Programmable Power's Solutions Business provides custom power supply systems and integrations. The solutions range from OEM integration for medical and semiconductor industries to modular avionics ATE power subsystems to turnkey solar array simulators for satellites. We also can modify power supplies to meet your application requirements.

AMETEK Programmable Power Solutions is especially skilled at providing custom power supply solutions using existing technology and previously developed integration solutions. This approach provides maximum functionality, short lead times and maximum value. Here is a brief listing of some of the types of solutions we can provide:

Catalog product modifications include:

- OEM power supplies for heating or burn-in

- AC stimulus for current transformer and circuit breaker testing

- Solar Array Simulation for satellites

- PV emulation for inverter verification

- Power racks for high energy solid state lasers

- DC power source and regenerative load for avionics actuator and motor testing

- Save your time, money and resources and let AMETEK Programmable Power Solutions solve your custom power conversion challenges for you.

Click here to take a look at this guide for more information.

More Product Information

- High Resolution IV curve simulates static and dynamic conditions

- Designed for high-speed Maximum Power Point Tracking (MPPT)

- 250HZ PP tracking speed

- Low output capacitance

- Active power factor correction (PFC)

- Standard LAN interface

- Full remote control via AMETEK m-SAS software and via SCPI commands

With the complexity of modern aerospace systems and components, stringent safety standards, and rapidly emerging trends and technologies, the aerospace and defense industry is facing a time of expeditious change. These industry trends shape aerospace manufacturers’ testing needs, growth objectives, and overall business goals. The reality is that aging aerospace facilities aren’t prepared to keep up with these rapid trends. Organizations seeking a competitive edge in the industry aim to achieve sustainable practices and regulatory compliance or explore new avenues in electric Vertical Take-Off and Landing (eVTOL) aircraft and space exploration. This demands testing facilities that are future-proofed for innovative solutions.

Scalable, zero trust architected, and edge-ready, the Integrated Edge Solution 5G is a rugged, compact, end-to-end private 5G standalone radio, core, and edge compute and connectivity solution providing ultra-reliable, low-latency bidirectional communication.

- O-RAN/3GPP-Compliant Vendor-Agnostic - Deploy cores and radios from multiple vendors with different capabilities and price points to maximize flexibility and scalability.

- Ubiquitous and Continuous Comms - Seamlessly connect edge nodes via terrestrial and non-terrestrial neworks including private 5G, WiFi, SATCOM, and much more.

- Comprehensive Network Solution - Integrated RAN and 5G Core across single-server network-in-a-box (NiB) or multi-server architectures per your application or program need.

A highly scalable, compact, secure, rugged rack server with the latest high-performance computing technologies to ensure peak performance and adaptability for a variety of ever-changing applications.

- Maximum Configurability, Flexibility, and Scalability - Quickly adjust your system’s performance to meet the constantly fluctuating demands of diverse data environments and ensure operational efficiency.

- Enhanced Compute + Connectivity - Process, analyze, store, retrieve, and transfer large amounts of actionable intelligence in seconds to improve decision-making and reduce response times.

- Ruggedized for Extremes - Tested to meet the toughest military and industrial standards to ensure the quality and reliability of our solutions within harsh and austere conditions.

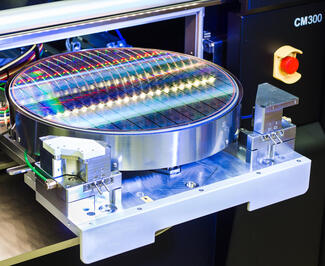

Flexibility

- Application flexibility: Coax, Triax, RF/mmW, High Power, Double Sided

- Temperatures range from -60°C to +300°C

- Surfaces are nickel or gold-plated

- Hybrid chuck design – operation with and without cooling unit

- Field-upgradeable: On-site cold upgrades for all main prober platforms

Highest Efficiency for Reduced Cost of Test

- Up to 25% lower air consumption (CDA) than other systems on the market with no compromise in transition times

- Up to 15% faster transition times than other systems on the market

When a catalog product cannot completely satisfy a requirement, AMETEK Programmable Power's Solutions Business provides custom power supply systems and integrations. The solutions range from OEM integration for medical and semiconductor industries to modular avionics ATE power subsystems to turnkey solar array simulators for satellites. We also can modify power supplies to meet your application requirements.

Highly scalable with unprecedented data transfer rates, the Hardware Isolation Platform is a dual-segment solution that combines cutting-edge security and adaptive capabilities to ensure guaranteed spacial isolation of critical data and optimize diverse workloads.

- Cross Domain Solution - Control comms and data transfer between domains of different classification levels with an FPGA hardware firewall.

- Data Isolation - Remote areas of memory create a data buffer between CPUs or virtual machines, securely storing frequently accessed data.

- Mixed Criticality - Integrate workloads with different criticalities on a single platform while prioritizing higher criticality tasks over lower ones.

Total power subsystem integration

- Ethernet communication

- Full sub-system wiring

- Single P.O.

- Custom interface to suit customer requirements

AMETEK Programmable Power

Programmable Precision AC & DC Sources, Loads and Custom Power Solutions