FormFactor - Cascade Ultra High-Power (UHP) - Enabling single-contact high-current/high-voltage test

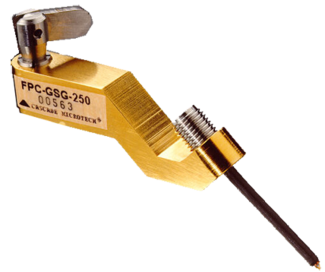

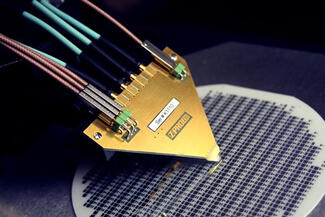

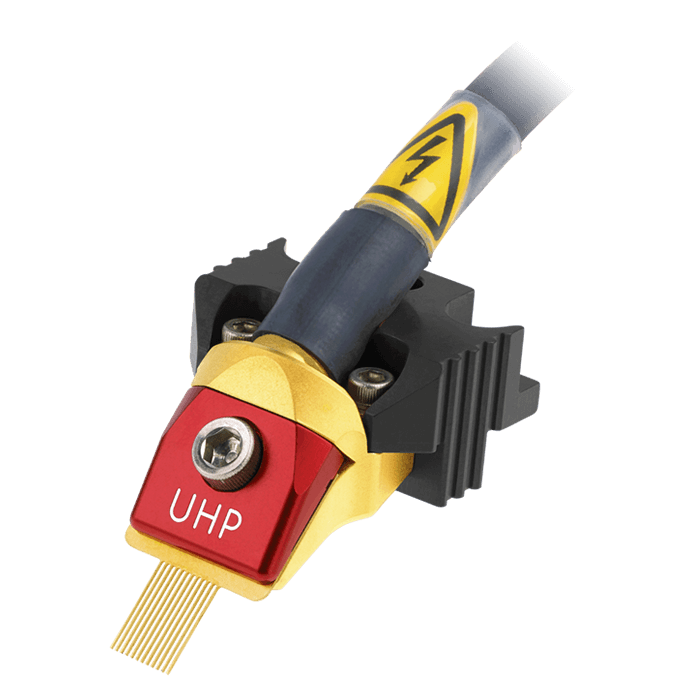

- Enables coaxial measurements up to 10,000 V and 300 A pulsed (600 A in a parallel configuration) with a single touchdown

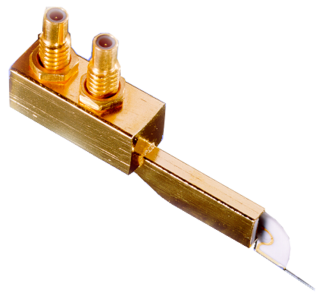

- Even distribution of high current with innovative multi-fingertip design

- Compatible with TESLA 200/300 mm power device characterization system

- Reduced measurement time by testing both high-voltage and high-current conditions with a single touchdown

- Accurate characterization of a wide range of pad sizes and test currents, with minimum pad damage and contact resistance

- Safe, reliable and repeatable high-current/voltage measurements over a wide temperature range (from -55°C to +300°C)

FormFactor’s Ultra-High-Power Probe (UHP), a high-voltage parametric probe, handles both high voltage (up to 10,000 V) and high current (up to 600 A) at a wide temperature range (-60ºC to 300ºC).

The high pulse current achieves full I-V characterization with one setup and one touchdown. Together with a TESLA on-wafer power device characterization system, the UHP fully utilizes the high-voltage/current capability of Keysight B1505A and N1265A Ultra High Current Expanders.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.