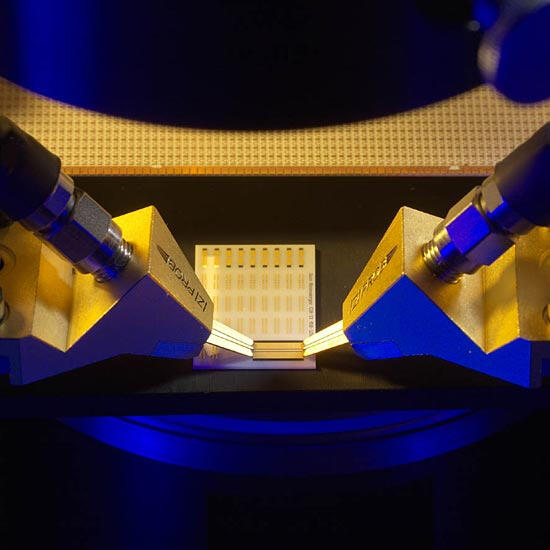

FormFactor - Cascade |Z| Probe® PCB - Robust RF test on PCB and ceramic

-

Replace costly and inflexible test fixtures with easy-to-use probe tips

-

Long lifetime – typically over 1,000,000 contacts

-

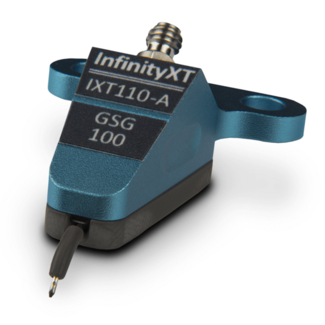

GS/SG footprint up to 4 GHz and GSG up to 20 GHz

-

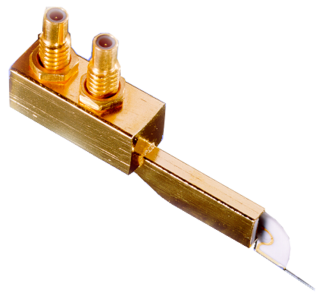

High-power RF test: up to 30 Watts

-

Test at temperatures from -60°C to 200°C

Flexibility is the key for efficient PCB and ceramic testing. The |Z| Probe® PCB is simple to align and handle and can be easily positioned. It optimally replaces costly test fixtures which are often inflexible. A robust design makes the |Z| Probe PCB easy to handle and offers a long working life typically more than one million (1,000,000) contacts.

The planar tip of the |Z| Probe PCB has precisely calculated, parallel, separate contact springs which move independently of one another, allowing a precise, quick and simple contact with the DUT, even if there are significant contact height differences. This unique feature as well as the overall very robust design of the |Z| Probe PCB ensures a long life and simple handling.

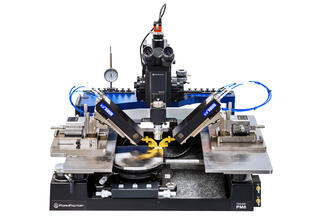

Used in conjunction with a manual probe system including probe positioners and calibration substrates, the |Z| Probe PCB becomes the ultimate tool for all RF circuit probing needs.

More Product Information

FormFactor, Inc.

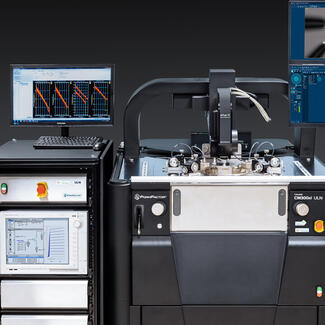

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.