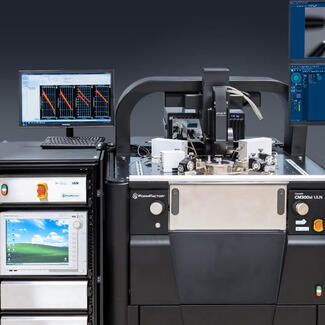

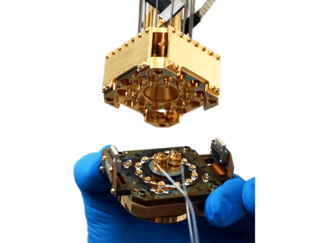

FormFactor - Cascade Shield Enclosure Light-tight probing

- Light-tight version and EMI-shielded version for low noise and light-sensitive measurements

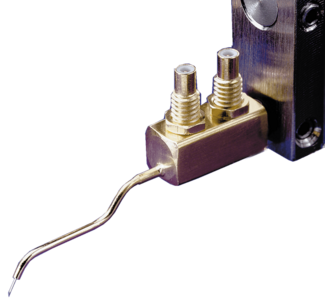

- Application flexibility, ideal for use in high frequency applications

- Sized to accommodate thermal chucks, laser cutter, and video equipment on the probe system

- Suitable for integration with vibration isolating tables

Shield Enclosures are designed for durable stability and sized to accommodate analytical probers equipped with all kinds of accessories, including thermal chucks, laser cutters, TV and emission cameras. The EMI-shielded version guarantees a light-tight and electromagnetically shielded environment for all sensitive measurements.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.