FormFactor - HPD Model HE-3-SSV-PT-2 - Dry Helium-3 Cryostat

-

Cryogen-free: cooling with two-stage pulse tube refrigerator (PTR)

-

Low vibration

-

Mechanical heat switch

-

Internal charcoal sorption pump

The Model HE-3-SSV-PT-2 is a single shot, cryogen-free, helium-3 cryostat for cooling samples in vacuum. It uses a two-stage pulse tube refrigerator (PTR) for initial system cool down.

Highly conductive flexible thermal links made from multiple strands of fine OFHC copper wires are used as thermal link between the two stages of PTR and both radiation shields. This design significantly reduces the vibrations that may be transmitted to the He-3 stage from the PTR.

Mechanical heat switches are used for the system operations.

An internal charcoal sorption pump is used to reduce the vapor pressure of the liquid He-3 and cool it down to its base temperature.

With our optimized design of the heat exchanger on the second stage regenerator of PTR, no additional compressor is needed for He-3 condensation.

The system is supplied with a complete set of thermometers and heaters to monitor and control the temperature of the various stages of the cryostat.

It also includes all the necessary valves and pressure gauges for safe and reliable system operation.

More Product Information

-

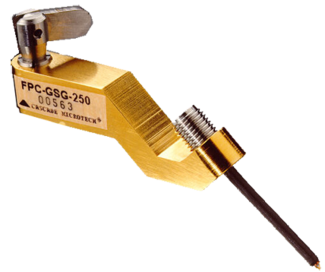

High power – 66 W at 2.4 GHz and 43 W at 5 GHz

-

Extremely low insertion loss of ≤ 0.4 dB (typical) up to 40 GHz

-

Excellent contact control and low contact resistance

-

High performance on any pad material (Al or Au)

-

Longest lifetime – typically one million (1,000,000) touchdowns

-

DC-40 GHz bandwidth

-

10 ps rise time

-

Low insertion and return loss

-

2 mils of tip-to-tip compliance

-

High probing angle and clearance

-

Sony ICX415 CCD sensor

-

Power over Ethernet option

-

Angled-head and board level variants

-

Video-iris lens control

-

Monochrome (G-046B) and color (G-046C) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

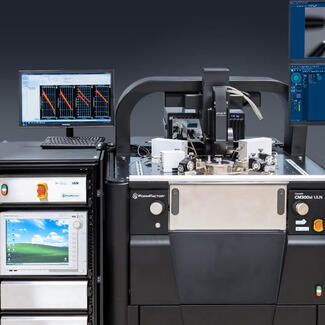

Highly stable granite base

-

Independent, coarse movement of X and Y axes, combined with easy fine adjustments

-

Re-configurable for DC, RF, mmW, FA, WLR and more

-

Full thermal range of -60°C to +300°C

-

Low-profile, straightforward design

-

Spacious top chambers for up to 12 positioners

-

Reduces electrical noise by providing a fully electromagnetically shielded, ultra-low-noise, light-tight environment

-

Enables accurate low-noise measurements of atto amperes, femtofarads and microvolts at temperatures down to -60°C

Mfg: Matrox

Model: DA5WINPU

Condition: Open Box

Description: Matrox Design Assistant 5 Flowchart-based Vision Software for Windows

-

Ultra-compact design

-

Affordable

-

Power over Ethernet

-

30.3 fps at full resolution

-

Monochrome (G-125B) and color (G-125C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Select between B 270 ASG protection glass and filter types: Jenofilt 217 IR cut filter, Hoya C-5000 IR cut filter, RG715 IR pass filter, or RG830 IR pass filter

-

IMX183 CMOS sensor

-

ALVIUM image processing

-

MIPI CSI-2 interface

-

Various hardware options

-

Monochrome (1800 C-2050m) and color (1800 C-2050c) models

-

ALVIUM® Technology for on-board image processing

-

MIPI CSI-2 interface with up to 4 lanes

-

Platform concept that enables the operation of different Alvium camera models with a common software

-

Hirose HR FHH55 FPC connector with minimum space requirements for a compact design

-

Precise sensor-to-lens mount alignment

-

Standard M3 mounting holes for top and bottom mounting, standard M2 mounting holes for front mounting

-

Industrial performance for embedded vision applications

-

Easy-to-install driver and code examples

-

IMX265 CMOS sensor

-

ALVIUM image processing

-

USB3 Vision

-

Various hardware options

-

Monochrome (1800 U-319m) and color (1800 U-319c) models

-

ALVIUM® Technology for on-board image processing

-

USB3 Vision interface for GenICam SFNC features

-

Platform concept that enables the operation of different Alvium camera models with a common software

-

Micro-B USB 3.1 Gen 1 connector with screw locks for industrial applications

-

Precise sensor-to-lens mount alignment

-

Standard M3 mounting holes for top and bottom mounting, standard M2 mounting holes for front mounting

-

Industrial performance for both embedded and machine vision applications

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.

Contact Details

FormFactor, Inc. Corporate Headquarters

7005 Southfront Road, Livermore, CA 94551, USA

Phone: 925-290-4000

Test & Measurement