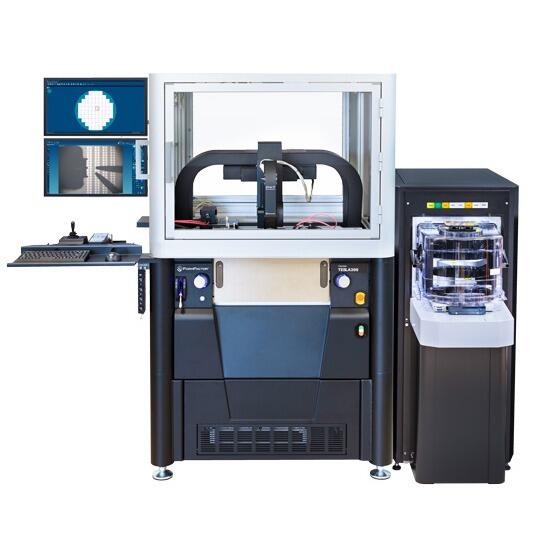

FormFactor - Cascade TESLA300 - 300 mm semi-/ fully-automated on-wafer power device characterization system

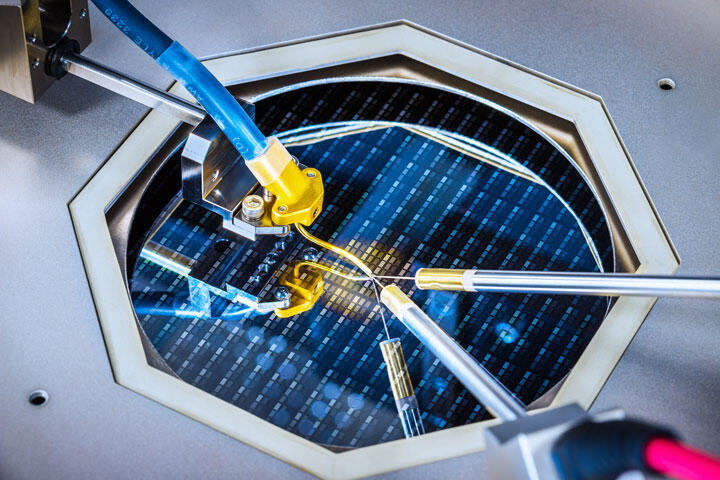

Gold-plated TESLA High-power MicroVac™ Chucks

- Prevent thin wafers from curling and breaking

- Advanced MicroVac chuck surface for minimum contact resistance between wafer and chuck

- Accurate Rds(on) measurement at high current

- Accurate UIS measurements at high temperature

The TESLA300 Advanced On-Wafer Power Semiconductor Probe System is an integrated high-power test solution that enables collection of accurate high-voltage and high-current measurement data up to 3 kV (triaxial) / 10 kV (coaxial) and 200 A (standard) / 600 A (high current), with complete operator safety.

The TESLA300 provides lab automation capabilities and enables high-power electrical measurements for device characterization, high-volume engineering and extremely challenging applications. It is also ideally suited in customized solutions, niche production applications, and emerging markets.

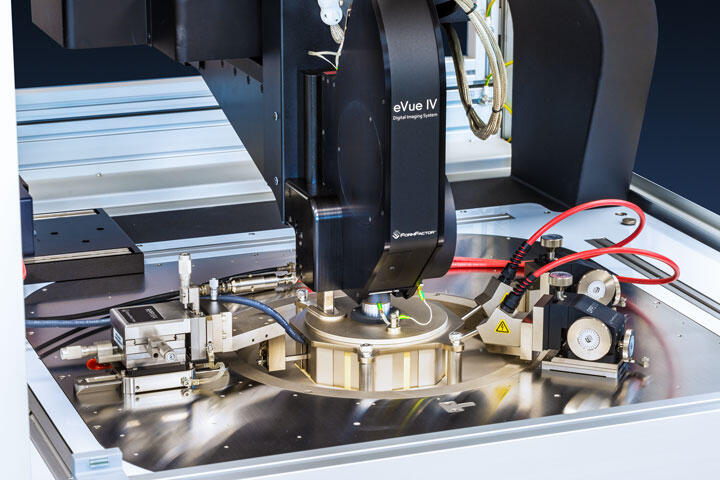

Patented AttoGuard technology built in TESLA300 significantly improves low-leakage and low-capacitance measurements. In combination with FormFactor’s patented TESLA FemtoGuard™ thermal chuck technology, the TESLA300 provides a fully guarded and shielded test environment. The high-power TESLA FemtoGuard chuck also incorporates MicroVac™ technology enabling low-contact resistance, thin wafer handling and maximum power dissipation.

Applications

- High Power

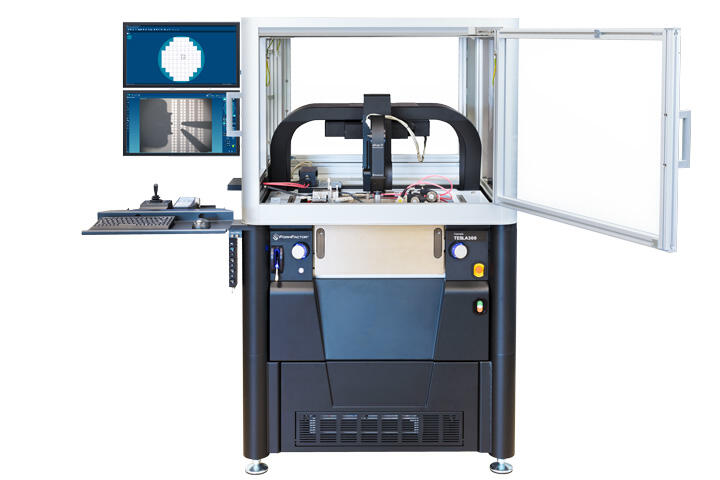

TUV-certified probing environment

- Safety-rated interlock system for high-power testing (meets EN 60947-5-1, EN 60204-1)

- Front, side and rear opening doors for ergonomic test setup and operation

- Side panel with cable pass-through for easy equipment configuration

- Full enclosure design (no light curtain) prevents accidentally tripping the safety interlock and stopping test

Top-lift wafer loading

- Eliminates lift-pins from chuck for best-in-class power device measurements

- Provides lowest contact resistance from wafer to chuck

- Supports fully automated testing up to 10kV by eliminating arcing point

- Superior performance for vertical device measurements (no lift pin holes under device)

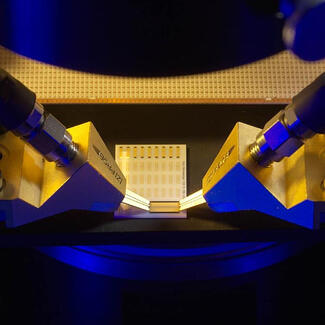

Rollout stage with quick access to auxiliary sites

- Full wafer access via locking roll-out stage

- Two patented auxiliary chucks

- Auxiliary chucks: High voltage 10 kV compatible multi-purpose mounts for substrates (cleaning, contact)

- Automated probe cleaning capabilities

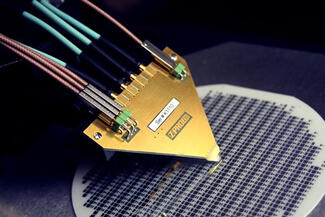

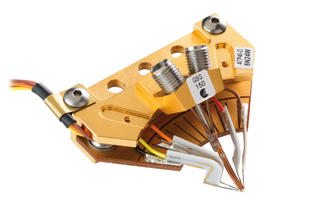

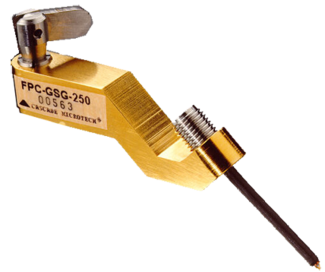

High-voltage/current Probes

- On-wafer power device characterization up to 10,000 V DC / 600 A

- Reduced probe and device destruction at high currents up to 20 A DC and 300 A pulse

- Increased isolation resistance and dielectric strength to provide full triaxial capability at high voltage (3,000 V) for low-leakage measurement

Connection panels

- Coaxial, triaxial, and pin jack feed-troughs available

- Limit cable strain and motion for measurement stability

- Instrument stays connected to back of panel

- Probe connection made at front of panel

- Simple to re-arrange cabling when needed

Seamless Integration

- Convenient instrument connection kits

- Seamless integration between Velox and analyzers/measurement software

- Easy and safe system integration with Keysight and Keithley power device analyzers

3D Manual Controls

- Virtual Platen Lift and XY knobs at front

- Intuitive, and precise movement of chuck in X, Y, and Z-direction

- Platen Lift enables extremely rapid and intuitive way in performing many alignment tasks like setting up the contact height

Material Handling Unit (MHU301)

- For fast handling of 200/300 mm wafers

- Load/unload wafer to hot/cold chuck (-60° C to +300° C)

- Integrated pre-aligner for flat/notch detection

- Barcode/2D Matrix code/OCR wafer code recognition from both sides (option)

- Quick Access Port option for higher throughput and additional wafer storage

- SEMI-compliant load port for up to 25 wafers

- For FOUP and FOSB 300 mm wafer cassettes

Thermal Measurements

- Wide range of extremly performant, reliable thermal chuck systems from ATT

- Flexibility from hot only to full thermal range of -60°C to +300°C

- Up to 25% lower air consumption (CDA) than other systems in the market (300l/min) with no compromise in transition times

- Up to 15% faster transition times than other systems in the market

- Patented MicroVac™ and FemtoGuard™ Technologies, providing ultra-low noise measurements and controlled leakage, low residual capacitance for repeatability and advanced measurement accuracy and speed

- Field-upgradeable: grows with your needs

Remote operation from home or anywhere in the world

- Safely and easily place probes down in contact with the test pads (full capability with motorized positioners)

- Safely move the wafer to different test sites

- View and manage live microscope viewing of the probes and the wafer

- View Wafer Map test plans

- Initiate remote test programs to gather and analyze test data

Velox Probe Station Control Software

- User-centered design minimizes training costs and enhances efficiency

- Windows 10 compatibility enables highest performance and safe operation with state-of-the-art hardware

- Comprehensive alignment functions – from simple wafer alignment and mapping to advanced probe-to-pad alignment over multiple temperatures for autonomous semiconductor test

- Simplified operation for inexperienced users: Reduced training costs with Workflow Guide and condensed graphical user interface

- VeloxPro option: SEMI E95-compliant test executive software that enables simplified and safe automation of the entire wafer test cycle

- Modern User Interface with Touch Screen: Convenient probe station operation with just a touch of a finger

- Access to Most Common Probe Station Functionalities: Fast and efficient probe station operation

- Intuitive and Customizable to Operator’s Needs: Simplified operation, even for inexperienced users

- Integrated Solution: Replaces mechanical joystick and eVue remote control

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.