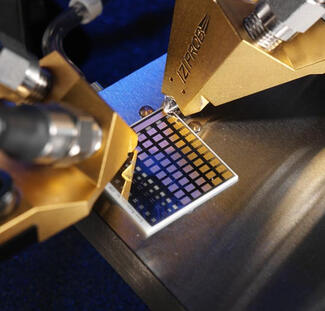

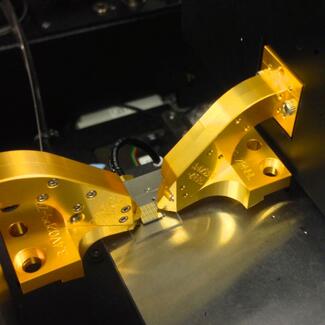

FormFactor - Cascade DC-Q Probe - Multi-contact DC probe with flat tip needles

- Power bypass inductance: 8 nH

- Standard DCQ probes have flat tip needles available in nickel-plated tungsten or BeCu with diameters of 0.75 mil, 1.0 mil and 1.5 mil.

- Supports collinear and non-standard needle configurations

- Up to 16 DC for standard; maximum of 24 DC for custom

- Ideal for probing the entire circuit for functional test

- DC probes can provide power or slow logic to circuit under test

The DCQ probes use controlled impedance, ceramic blade needles for low noise and high performance. This needle style allows the placement of high-quality bypass capacitors with very little series inductance due to their close proximity to the probe tip. All of the needles are connected to a common ground plane but individual needles can be easily (ground) isolated for additional low noise performance. A maximum of 16 needles are available for standard configurations and a maximum of 24 needles for custom configurations.

More Product Information

FormFactor, Inc.

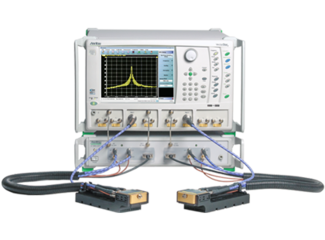

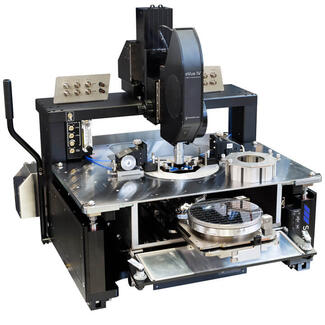

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.