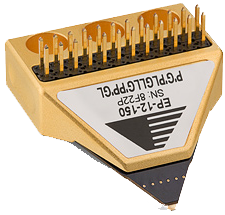

FormFactor - Cascade Eye-Pass Probe - Durable multi-contact wafer probe with controlled impedance power bypass technology

- High performance power bypassing provides low-impedance and resonant-free connections to 20 GHz

- RF bandwidth to 500 MHz

- Long probe life: > 250,000 contacts

- Beryllium-copper tips for gold pads or tungsten for aluminum pads

- Oscillation-free testing of wide-bandwidth analog circuits

- Use with ACP series probes to provide functional at-speed testing for known-good-die

- Mix multiple contact types: Ground, Power (Standard or Eye-Pass), Logic/Signal

- Low and repeatable contact resistance on aluminum pads ( < 0.25 Ω on Al, < 0.01 Ω on Au)

The multi-contact Eye-Pass probe provides controlled impedance power connections enabling functional testing of even the most challenging circuits on-wafer. The high-durability composite multi-finger tip provides high compliance and ensures precise alignment. This custom probe allows the user to select the footprint pattern best suited for the application, with up to 12 contacts per probe head. Available contact types are ground, logic, standard and Eye-Pass power supply, power supply sense, and ac signal.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.