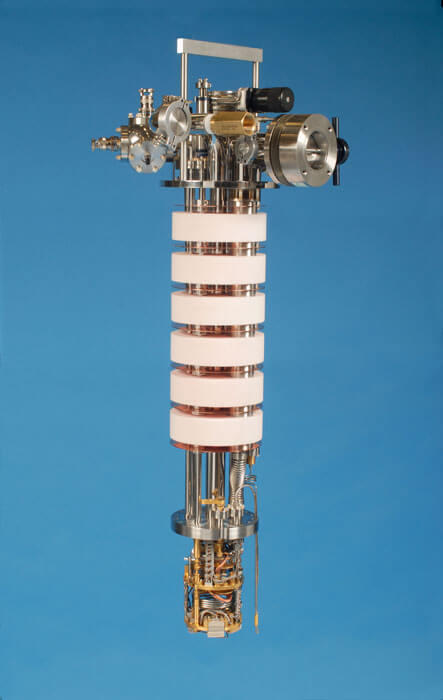

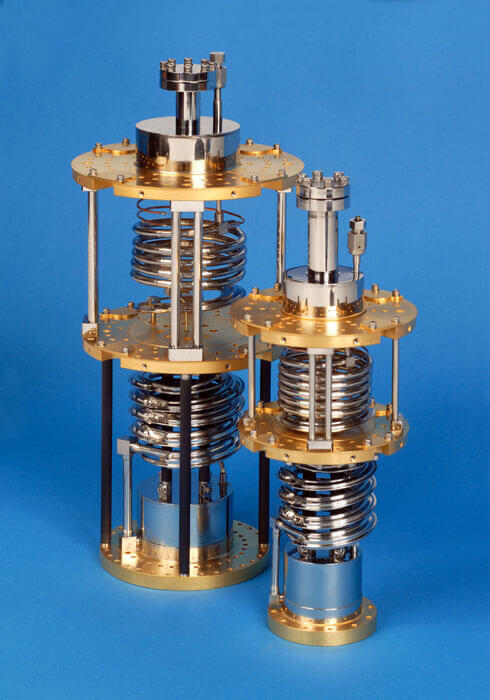

FormFactor - HPD Wet DR Series - Wet Dilution Refrigerator Systems

-

Proven technology: designed in conjunction with several top STM groups in the world

-

Quiet, low vibration operation

-

Low running costs and reduced maintenance

-

Easy operation and fast cool-down; load sample when the system is cold for TL models

-

Calibrated RuO and CMN thermometry read by model 372S resistance bridge are installed on the mixing chamber plate

FormFactor’s wet dilution refrigerators has two series of products: the Wet DR-50/250/500 and Wet DR-50-TL/250-TL/500-TL.

Both series of dilution refrigerators enable easy and cost-effective cooling to temperatures between 35 to 10 mK.

The sample of Wet DR-50/250/500 systems is located in a normal vacuum (HV) space. It can be loaded when the system is warm with the vacuum can open.

The TL series has been optimized for scanning tunneling microscopy (STM) applications. The sample can be loaded into the ultra-high vacuum (UHV) space from the top of the dilution refrigerator insert when the cryostat is cold.

Custom wiring is available.

Both fully automated and manually operated gas handling systems are available.

More Product Information

-

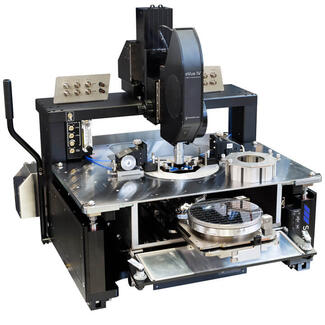

Best solution for high accuracy IV/CV, low-noise and 1/f measurements with PureLine, AutoGuard and next generation MicroChamber technologies

-

Enables up to 5x faster time to accurate data

-

Advanced 4-axis semi-automatic stage for accurate positioning and repeatable probe-to-pad contact

-

RF/microwave device characterization, 1/f, WLR, FA and design debug

-

Wide range of extremly performant, reliable thermal chuck systems from ATT

-

Easy on-screen navigation, wafer mapping, and operation of accessories and thermal systems with Velox

-

User-centered design minimizes training costs and enhances efficiency

-

Different substrate carriers for wafers up to 200 mm or single dies

-

Probe cards and/or up to eight positioners

-

Probe positioners placed inside vacuum chamber

-

Short and stable probe arms

-

Joystick controller

-

Manual probe positioners with rotary feed-throughs

-

Software control of chuck for fast step-and-repeat testing of the entire wafer

-

Fast step-and-repeat testing of the whole wafer

-

User-centered design minimizes training costs and enhances efficiency

-

Enables wafer probing up to 100 A pulsed and 10A DC

-

Innovative multi-fingertip design provides even distribution of current

-

Supports up to 500 V

-

Replaceable Tungsten probe tips

-

Temperature range of -60°C to 300°C

-

Minimal contact resistance at the pad-tip junction to reduce heating during measurements, with fewer probe marks

-

Prevents against thermal runaway

-

Measure devices on wafer at higher currents than ever before

-

Small scrub minimizes damage to aluminum pad

-

Small footprint – tip fits on a 1 mm pad

Customized Solutions for a Variety of Challenging Applications

-

Light-tight version and EMI-shielded version for low noise and light-sensitive measurements

-

Application flexibility, ideal for use in high frequency applications

-

Sized to accommodate thermal chucks, laser cutter, and video equipment on the probe system

-

Suitable for integration with vibration isolating tables

-

Re-configurable for DC, RF, mmW, FA, WLR and more

-

Thermal range: -60˚C to 300˚C available

-

Upgrade path to meet your future needs

-

Stable and repeatable measurements over a wide thermal range

-

Moisture-free, light-tight and EMI-shielded test environment with MicroChamber® technology

-

Advanced EMI-shielding with PureLine with AttoGuard technologies

-

Best solution for low-noise and 1/f measurements

-

Minimize AC and spectral noise

-

Minimizes settling times for efficient measurements, without compromising accuracy over full thermal range

-

Locking roll-out stage

-

Innovative microscope remote control

-

Intuitive ergonomic stage controls

-

Quick, safe, and comfortable wafer access

-

Easy on-wafer navigation

-

Fast setup and test data gathering

-

Dedicated Velox version for manual probe stations

-

AugmentedAlign tool with on screen markers for improved RF measurement accuracy

WeTrack® stands as a one-of-a-kind service developed, possessed, and operated by Safran Defense & Space, Inc. (formerly Safran Data Systems, Inc.). Leverage its autonomous network of radio frequency (RF) sensors to attain precise orbital positions with high data update rates, enhancing your decision-making capabilities across all orbit scenarios, thanks to our global coverage. With automated sensors for detection and tracking, stay well-informed 24 hour, every day of the year.

Our patented technology, designed for passive satellite emissions reception, provides comprehensive coverage of all orbits, boasting multiple networks deployed in the United States, Europe, and Asia. WeTrack® grants real-time access to information through a secure web portal.

-

Power bypass inductance: 8 nH

-

Standard DCQ probes have flat tip needles available in nickel-plated tungsten or BeCu with diameters of 0.75 mil, 1.0 mil and 1.5 mil.

-

Supports collinear and non-standard needle configurations

-

Up to 16 DC for standard; maximum of 24 DC for custom

-

Ideal for probing the entire circuit for functional test

-

DC probes can provide power or slow logic to circuit under test

-

Customizable configuration up to 25 contacts: RF, Eye-Pass power, ground, logic

-

Lithographically-defined tips allow automated over temperature measurement on pads as small as 30 µm x 50 µm

-

Low and repeatable contact resistance on aluminum pads (< 0.05 Ω) ensures accurate results

-

Durable probe structure ensures more than 250,000 contacts

-

Able to measure from -40°C to +125°C without compromising performance or accuracy of specifications

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.

Contact Details

FormFactor, Inc. Corporate Headquarters

7005 Southfront Road, Livermore, CA 94551, USA

Phone: 925-290-4000

Test & Measurement