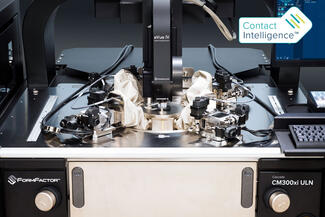

FormFactor - Cascade Custom Probe Systems - Comprehensive technical and application know-how for challenging applications

Customized Solutions for a Variety of Challenging Applications

We are your partner for challenging applications. Our comprehensive technical and application know-how over all probe system platforms and our expertise for customized products is based on an extensive experience over many years. We offer a special demo support in-house or at the customer, as well as after sales support for complicated setups.

Customization Examples

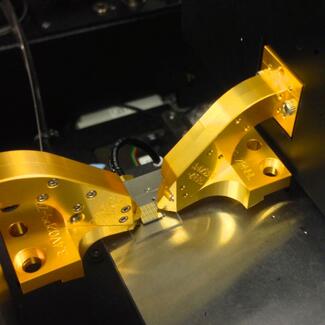

Waveguide with customized bracket

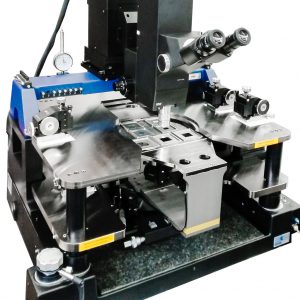

300 mm chuck with large tweezer pocket

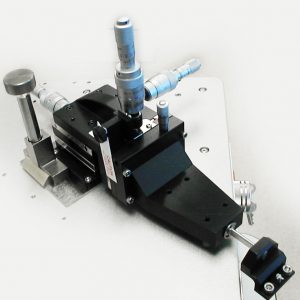

RF positioner with micrometer screws

Double-side setup for emission microscopy

Combined microscope movement for scope and black body

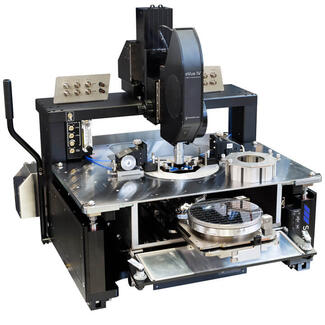

mmW setup with North/South positioner platform

More Product Information

- Substrate material: High-resistivity silicon

- Substrate thickness: 275 µm

- Dielectric constant: 11.8

- Nominal Z0: 50 Ω

High flexibility

- Re-configurable for DC, RF, mmW, FA, WLR and more

- Thermal range: -60˚C to 300˚C available

- Upgrade path to meet your future needs

- Stable and repeatable measurements over a wide thermal range

See "Specifications & Details" tab for more key features

-

Ease of use – Less experienced operators can perform DC measurements by simply pushing a button. This reduces the need of experienced users full time on each system.

-

Reduced Soak Time – The system will automatically re-align the probes to the pads if they drift from alignment. This reduces test time and increases throughput.

-

Unattended Use – Measurements can be left running over night or the weekend, testing all devices on the wafer, and at different temperatures without the need of an operator.

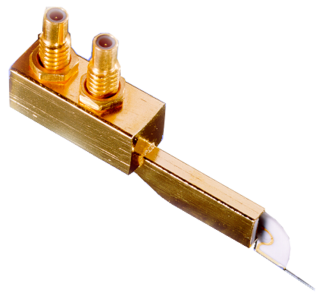

- Ultra-low, fA-level current and fF-level capacitance measurements from -65 °C to + 300 °C

- Guarantees fully-guarded measurements to fA and fF levels

- Individual connectors provide force-sense connection for quasi-Kelvin and CV measurements

- Allows probing of different pad materials and sizes

- Fast replacement of worn probes without the need for tools

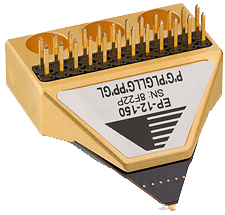

- Choice of Series resistance or Termination (signal line to ground)

- Use of High Performance RF Resistors

- Choice of Resistor values available

- Choice of body styles, Infinity, ACP or FPC

- Can help to stabilize oscillations in high-gain devices

- Impedance match to low dynamic resistance laser diodes

- Custom configured for your application

Linea SWIR features a cutting-edge InGaAs sensor in a compact package that is suitable for a wide variety of applications. With exceptional responsivity and low noise, this camera allows customers to see their products like never before. Linea SWIR is available as a 1k resolution camera with highly responsive 12.5 µm pixels, or a 512 resolution camera with larger 25 µm pixels.

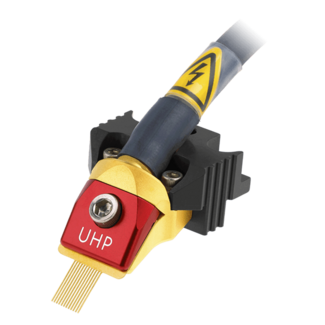

- Enables coaxial measurements up to 10,000 V and 300 A pulsed (600 A in a parallel configuration) with a single touchdown

- Even distribution of high current with innovative multi-fingertip design

- Compatible with TESLA 200/300 mm power device characterization system

- Reduced measurement time by testing both high-voltage and high-current conditions with a single touchdown

- Accurate characterization of a wide range of pad sizes and test currents, with minimum pad damage and contact resistance

- Safe, reliable and repeatable high-current/voltage measurements over a wide temperature range (from -55°C to +300°C)

- High performance power bypassing provides low-impedance and resonant-free connections to 20 GHz

- RF bandwidth to 500 MHz

- Long probe life: > 250,000 contacts

- Beryllium-copper tips for gold pads or tungsten for aluminum pads

- Oscillation-free testing of wide-bandwidth analog circuits

- Use with ACP series probes to provide functional at-speed testing for known-good-die

- Mix multiple contact types: Ground, Power (Standard or Eye-Pass), Logic/Signal

- Low and repeatable contact resistance on aluminum pads ( < 0.25 Ω on Al, < 0.01 Ω on Au)

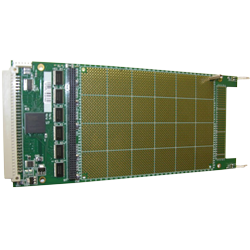

- 96 digital lines configurable as either input or output

- Five available power supply rails for custom designs

- Mix and match with standard SMIP switching and digital I/O modules to create high density configurations

- VXI plug&play driver simplifies software development

- On-board connector header for simplified migration to PCB implementation

- Access to 16 MHz clock for use in complex designs

- Multiple front panel connector options

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.