FormFactor - Cascade DCP 100 Series Probe - Delivers superior guarding and shielding

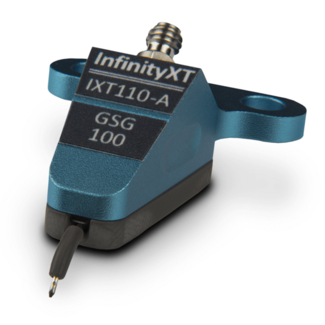

- High-quality construction with low-noise electrical performance

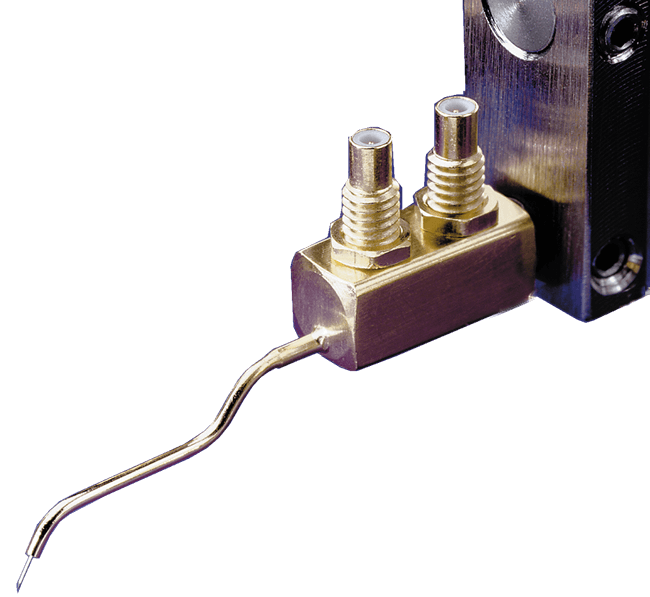

- Kelvin version for convenient 4-point measurements

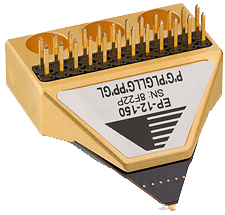

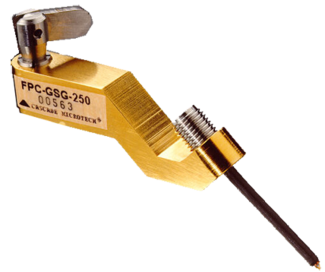

- Replaceable coaxial probe tips, with choice of tip radii, and full electrical guard to the probe tip

- SSMC 50 connectors

- Ultra-low, fA and fF measurements from -65 º C to 150 º C

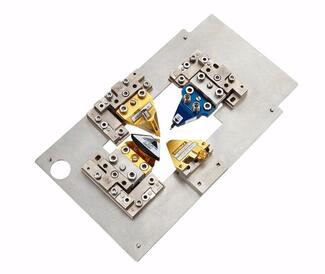

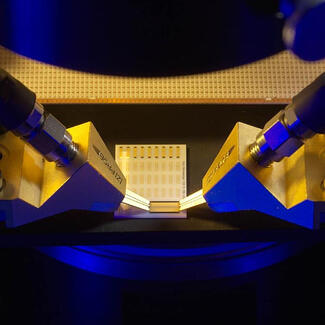

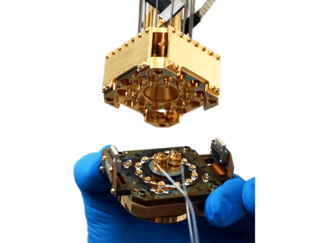

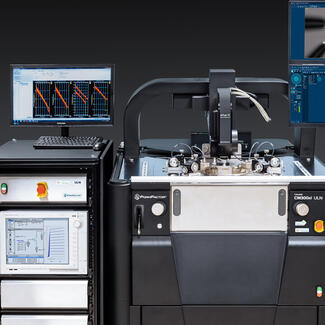

The DCP100 delivers the measurement accuracy needed for advanced on-wafer process, device characterization and reliability testing. With superior guarding and shielding, these probes overcome the performance limitations of non-coaxial needle probes. They are integrally designed as part of a complete measurement solution, these probes are highly reliable, stable and repeatable.

Advantages

- Ultra-low, fA and fF measurements from -65 º C to 150 º C

- Full electrical guard to the probe tip

- Integrally designed as part of Cascade’s complete measurement solution

- Highly reliable, stable and repeatable

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.