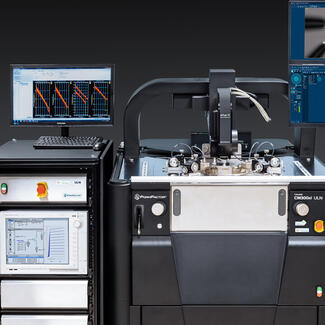

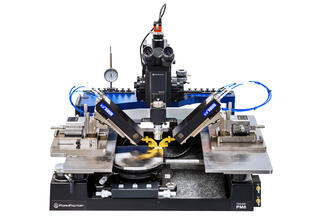

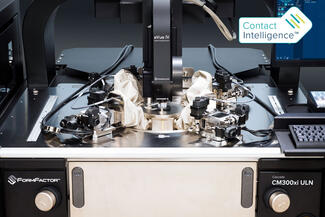

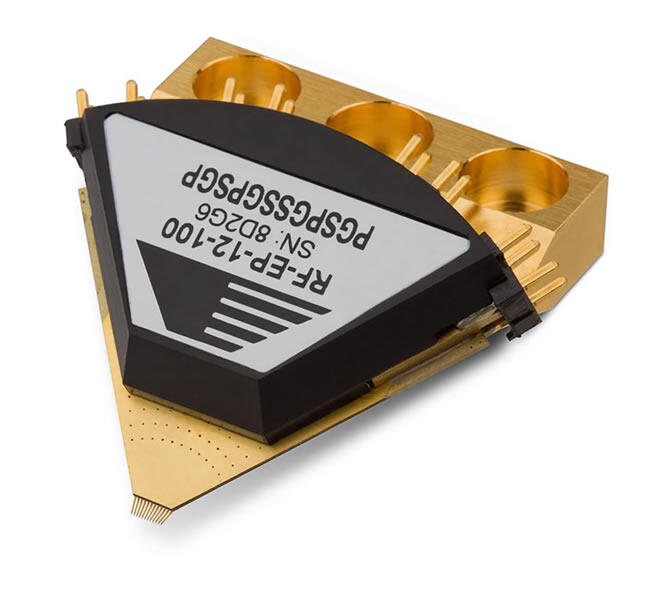

FormFactor - Cascade Unity Probe - Multicontact probe for RFIC engineering test

- Up to 12 contacts; any contact can be DC, Power, Logic to 500 MHz,or RF to 20 GHz

- Online design configuration tool helps you to specify your probe in minutes

- All designs are fully quadrant compatible

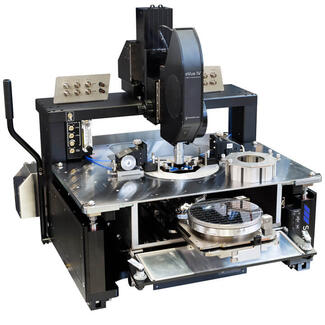

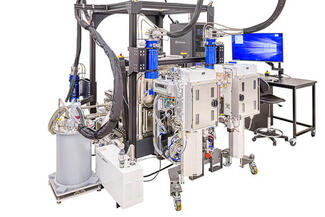

- Full solution includes probes, calibration substrates, stations, accessories and software

- Scalable architecture for future needs

The multi-contact Unity Probe provides highly flexible configurability, unprecedented durability and ease-of use for RFIC engineering test. Unlike “bent-to-order” needle-probe solutions, Unity probes are quickly “built-to-order” with a precision tip cluster featuring multiple independently compliant fingers to isolate chip components from probing stresses — maximizing probe life and durability. Each contact can be configured to one or several contact types and frequencies, and the Unity Probe delivers on the legendary quality you’ve come to expect from our comprehensive suite of probing solutions.

Use our online tool to capture your design requirements and receive a quote.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.