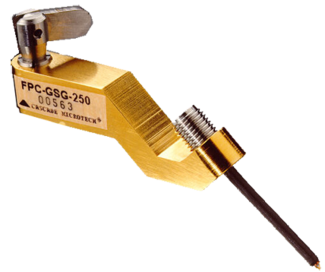

FormFactor - Cascade High Current Probe - Test power devices on wafer with high-performance and low-contact resistance on smaller pads

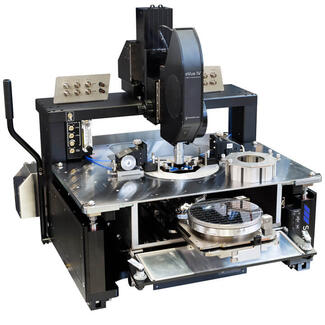

- Enables wafer probing up to 100 A pulsed and 10A DC

- Innovative multi-fingertip design provides even distribution of current

- Supports up to 500 V

- Replaceable Tungsten probe tips

- Temperature range of -60°C to 300°C

- Minimal contact resistance at the pad-tip junction to reduce heating during measurements, with fewer probe marks

- Prevents against thermal runaway

- Measure devices on wafer at higher currents than ever before

- Small scrub minimizes damage to aluminum pad

- Small footprint – tip fits on a 1 mm pad

Designed specifically for testing power devices on wafer, the HCP probe reduces probe and device destruction at high currents by minimizing contact resistance at the wafer-to-probe interface to prevent device heating at the tip. The innovative multi-finger design distributes the current over multiple contact points at the tip and is joined by a single heatsink which pulls heat from the probe tip.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.