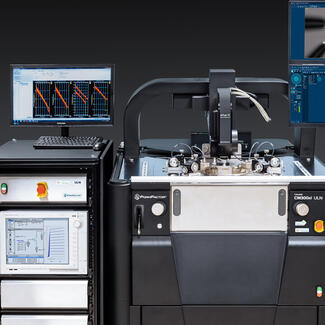

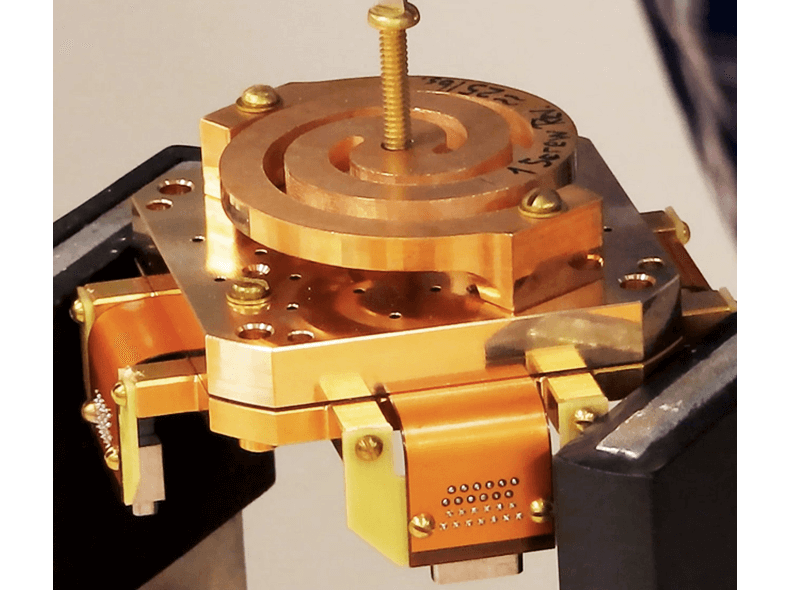

FormFactor - HPD PQ500 - Cryogenic Probe Socket Solution

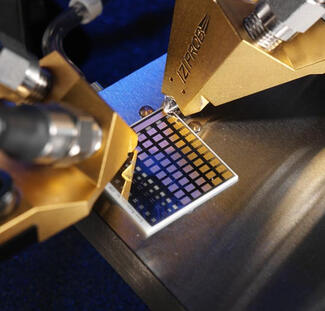

- Tests and validates performance directly on silicon without post-dicing packaging

- Dramatically reduces time to data and shortens development cycles

- Enables high scalability for high volume manufacturing

- Offers flexibility in chip design with full grid probing

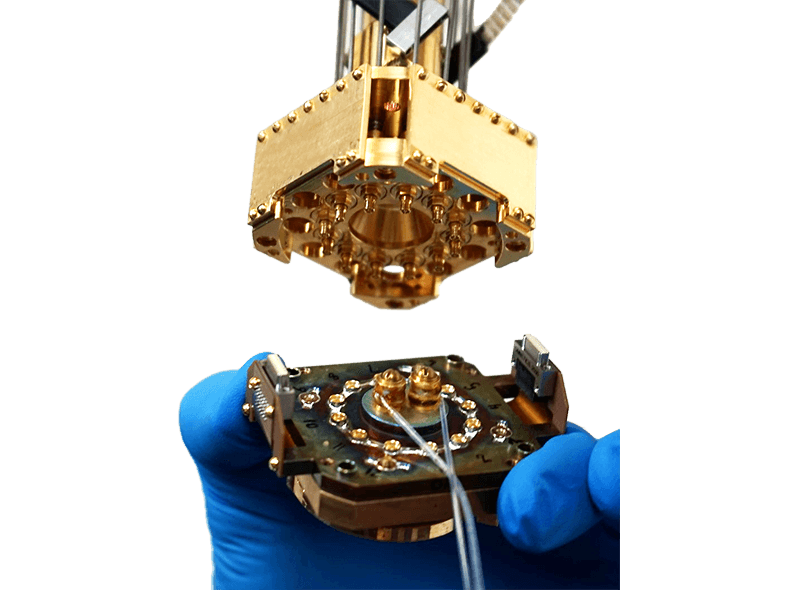

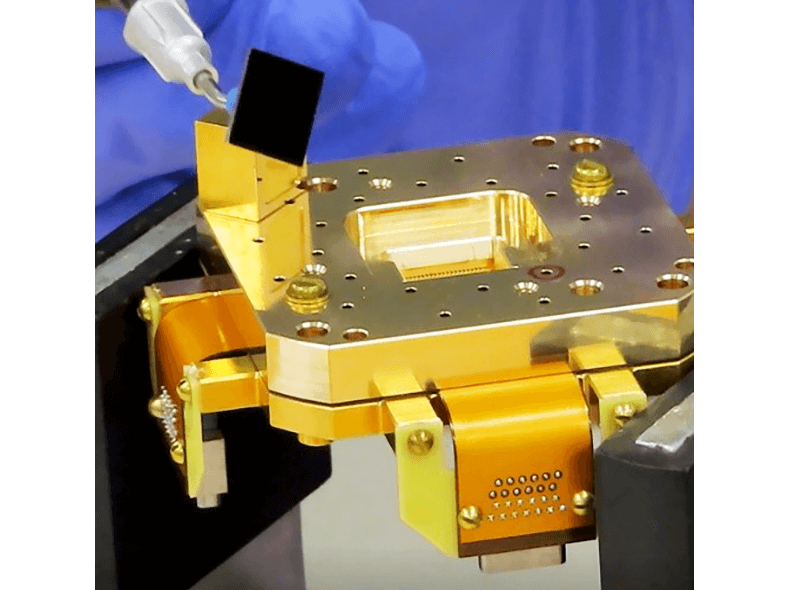

The HPD PQ500, a first-of-its-kind, cryostat-agnostic, high-density RF and DC socket interface, enables researchers and developers to test chips without wire bonding and packaging. The cryogenic probe socket solution can be used at mK temperatures, adaptable to an existing cryostat, accommodating small pitches, and capable of having an extremely high channel capacity.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.