FormFactor - Cascade Vibration Isolation Tables - Tables from simple to highly sensitive

- Designed for use with specific Probe Systems

- Tables to suit all facility requirements and applications

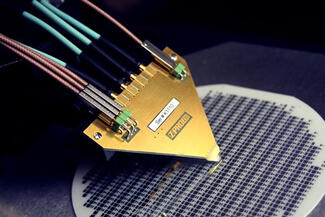

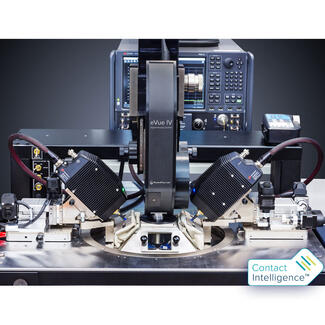

- Stable probing, even in submicron range

- Granite platen ensures rigidity and temperature stability

- Can be combined with the Shield Enclosures

Full range of vibration isolation tables

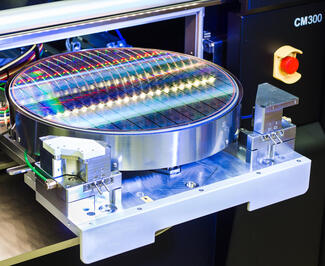

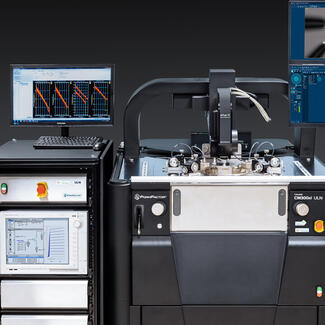

Working with increasingly small scales of reference means that any vibration however minimal, even from the equipment itself, will seriously degrade a probe station’s performance. Slight vibrations will cause the probes to jump and miss their contacts and the microscope image will be blurred. Our range of vibration isolation tables includes a simple table for general working conditions as well as specifically designed tables for very sensitive measurements such as in the submicron range.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.