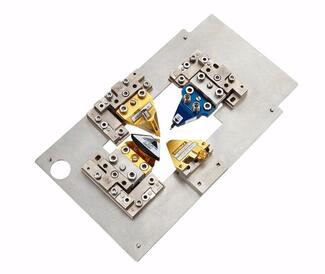

FormFactor - Cascade Resistive Matching and Termination - Custom configured for your application

- Choice of Series resistance or Termination (signal line to ground)

- Use of High Performance RF Resistors

- Choice of Resistor values available

- Choice of body styles, Infinity, ACP or FPC

- Can help to stabilize oscillations in high-gain devices

- Impedance match to low dynamic resistance laser diodes

- Custom configured for your application

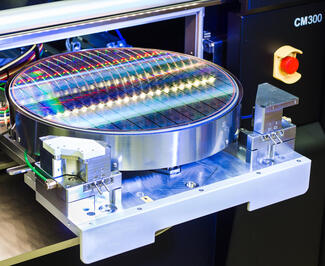

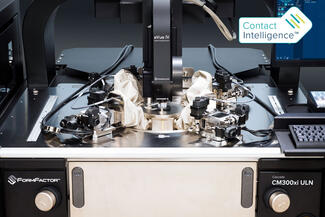

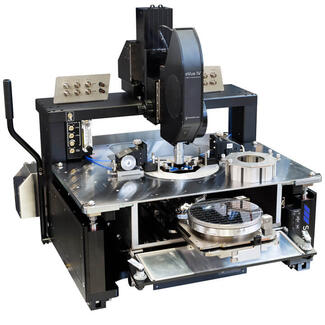

Resistive Impedance Matching Probes and Termination probes are available for the following probe families: Infinity; ACP; FPC, in multiple configurations. We use high performance / high quality RF resistors for these Matching or Termination probes and the resistors are placed as close as possible to the tip/DUT, to minimize the path length between the DUT and the resistor. The available Resistance values are limited and are listed in the request form. These types of Impedance Matching and Termination probes are used in various application such as with laser diodes, Transmission Line Pulse, ensure better termination of 50 ohm test equipment when mated to high impedance devices, etc.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.