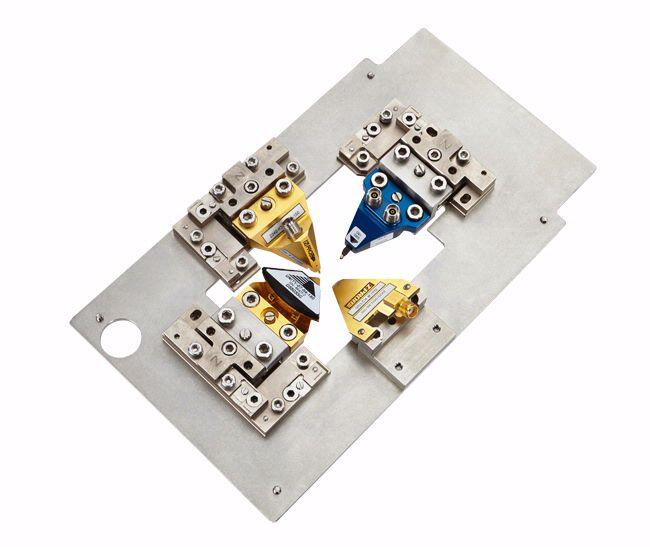

FormFactor - Cascade QuadCard™ - Cost-effective, versatile probe card solution

- Accommodates a combination of up to four Cascade Microtech probes

- Configurable for mixed-signal RF/mmW testing

- Quick and easy repairs to be performed in the field, by simply replacing individual probes

- Adaptable to new device layouts by exchanging individual probes

The QuadCard probe card is the industry’s first configurable, multi-quadrant probe adapter that employs innovative fine probe aligners to mount up to four FormFactor probes on a single probe card. It is designed to accommodate a combination of our probes such as Infinity Probes®, ACP probes, |Z| Probes® and Multi-|Z| Probes, which are aligned individually by the fine probe aligners.

More Product Information

- Coaxial and triaxial measurements up to 10,000 V

- High-quality construction with low-noise electrical performance

- Replaceable probe tips in a variety of tip sizes

- Temperature range of of -60°C to 300°C

- Triaxial measurement ensures a much better understanding of device leakage in the off state

- Highly reliable, stable and repeatable measurements

- Integrally designed as part of a complete measurement solution

- Lithographic thin-film construction

- Excellent crosstalk characteristics

- Non-oxidizing nickel alloy tips

- Innovative force delivery mechanism

- 40GHz, 50GHz, 67GHz, 110GHz and 145GHz connectors available

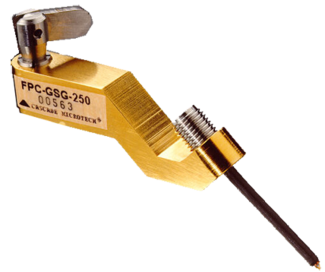

- GSG, SG, GS, GSGSG, GSSG, SGS configurations

- 50 to 250 µm pitches (other pitches available on request)

- High current version (2 A) available

Advantages

- Superior field confinement reduces unwanted couplings to nearby devices and transmission modes

- Superior measurement accuracy and repeatability

- Small scrub minimizes damage to aluminum pad

- Typical contact resistance < 0. 05 Ω on Al, <0.02Ω on Au

- Save valuable wafer space and reduce pad parasitics by being able to shrink pad geometries to 25 x 35 µ m (best case)

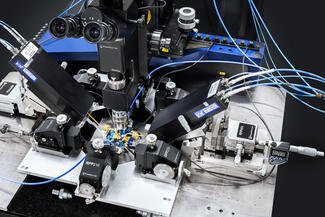

DC, RF and Optical Probe Positioning for Highest Accuracy Measurements

FormFactor offers a wide variety of manual and motorized probe positioners for any application from DC to terahertz measurements and beyond.

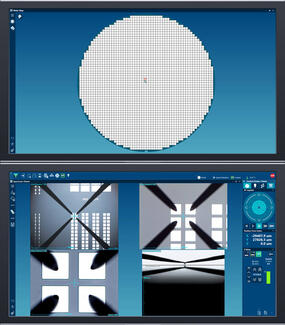

Floating Action Buttons

- Easy and fast setup of camera views

- Go to Light and Image Settings of the selected camera view with only one mouse click

Workflow Wizard

- Guided workflows for wafer setups, alignment tools and Autonomous Assistants

- Workflow wizard shows task-relevant settings and options only

- Wizard settings can be corrected anytime – no need to restart the wizard

- Wizard helps with intelligent solutions in case of error

See "Specifications & Details" tab for more key features

-

Die-to-die stepping time of under 100 ms

-

Up to 20 dies/sec (70,000 dies/hour) with MultiDie Testing technology

-

Even extreme variations in height, such as the case with warped wafers, can be compensated

-

Interfaces to all major analysis instrumentation, optics software and testers

-

Access to top side and bottom side of device under test (DUT)

-

Highly accurate light measurement

-

Test automation out-of-cassette for 24/7 operation

Cryogenic Temperatures

- Fully isolated experiment space for true 4K temperatures during probing

- Cryogenic positioners to provide large travel ranges without warming up the device

- Integrated helium pot for high temperature stability of the device under test

- Fully dry cryogen-free cooler eliminates the need for expensive helium circulation systems

- Rapid cool liquid nitrogen option for faster cool down times

See "Specifications & Details" tab for more key features

-

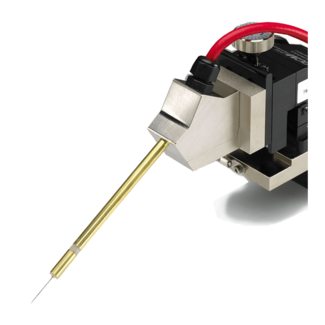

Unique Air Coplanar tip design with choice of beryllium copper (BeCu) or tungsten tip material

-

DC to 110 GHz models available in single and dual line versions

-

Low insertion and return loss with ultra-low-loss ( -L ) versions

-

Excellent crosstalk characteristics

-

Wide operating temperature -65 ° C to + 200 ° C

-

Wide range of pitches available, from 50 to 1250 µm

-

Individually supported contacts

-

Reduced contact (RC) probe tips for small pads

-

BeCu tip provides rugged, repeatable contact on gold pads

Optimized Measurement Setup

- Multi-purpose SIGMA instrument integration kit

- Shorter cabling and universal chuck connection

- Triax probe with protected guard

- Optimized signal path

- Safe probe tip exchange

- Seamless integration of various analyzers

High Power Chuck

- Triax design for low-leakage measurements up to 3 kV

- Special chuck surface coating

- High-isolation ready

- High-current measurement up to 100 A with lowest contact resistance

- Optional upgrade for 10 kV (coax) operating voltage

- Thin wafer handling capability

Safe Operation

- Arcing protection

- Shield Enclosure with interlock

- Advanced grounding concept

- Maximum protection from high-voltage shock for users and devices

- Common ground protection for all instruments

- EMI/light-tight shielded environment

- DC-40 GHz bandwidth

- 10 ps rise time

- Low insertion and return loss

- 2 mils of tip-to-tip compliance

- High probing angle and clearance

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.