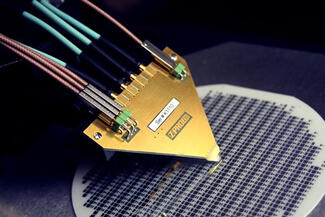

FormFactor - Cascade WPH Probe - Multi-contact DC probe with full-radius needles

- Full-radius, nickel-plated tungsten needles

- Power bypass inductance: 16 nH

- Supports collinear and non-standard needle configurations

- Support up to a maximum of 12 ceramic blades DC needles / contacts

- Ideal for probing the entire circuit for functional test

- DC probes can provide power or slow logic to circuit under test

The WPH probes feature up to 12 ceramic-bladed, nickel-plated, tungsten needles with a 2 x 12 square pin cable interface. The circuit board has been laid out such that both series and shunt components can be added to the signal path of each needle.

More Product Information

OptoVue

- Revolutionary technology advancement for wafer and die-level photonics probing

- Real-time in-situ calibrations

- Singulated die testing

- True die-level edge coupling

- In-situ power measurements

- Advanced calibration technologies

- Enables autonomous measurements

Horizontal Die-Level Edge Coupling

- Highest accuracy in test results

- Lowest coupling loss

- Repeatable measurement results due to exclusive automated fiber-to-facet alignment technology

- Reduced risk of damaging fibers with collision avoidance technology

- Ease of use for less experienced users

- Enables close simulation of real-world conditions with device performance closest to the final application

See "Specifications & Details" tab for more key features

Cryogenic Temperatures

- Fully isolated experiment space for true 4K temperatures during probing

- Cryogenic positioners to provide large travel ranges without warming up the device

- Integrated helium pot for high temperature stability of the device under test

- Fully dry cryogen-free cooler eliminates the need for expensive helium circulation systems

- Rapid cool liquid nitrogen option for faster cool down times

See "Specifications & Details" tab for more key features

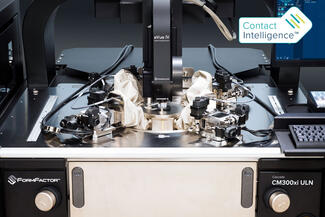

Superior Mechanics

- Highly stable granite base

- Independent, coarse movement of X and Y axes, combined with easy fine adjustments

- Excellent measurement accuracy and repeatability

- Fast navigation and high-precision probe positioning

See "Specifications & Details" tab for more key features

- Ideal for multiport RF/Microwave and high-speed digital signal testing

- Mix DC and RF/Microwave signals on one probe

- Long lifetime – typically over one million (1,000,000) touchdowns

- Excellent performance in temperatures ranging from 10 K to 200°C

- Probe on any pad material with no damage

-

Unique Air Coplanar tip design with choice of beryllium copper (BeCu) or tungsten tip material

-

DC to 110 GHz models available in single and dual line versions

-

Low insertion and return loss with ultra-low-loss ( -L ) versions

-

Excellent crosstalk characteristics

-

Wide operating temperature -65 ° C to + 200 ° C

-

Wide range of pitches available, from 50 to 1250 µm

-

Individually supported contacts

-

Reduced contact (RC) probe tips for small pads

-

BeCu tip provides rugged, repeatable contact on gold pads

Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Use with liquid nitrogen or helium, depending on the target temperature. Or use of cryo-cooler for dry-cooling option.

- Accessories available, such as black bodies and optical motion analysis tools

- Optional upgrade for 300 mm wafer

- Designed for industrial environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

- Ideal for small structures

See "Specifications & Details" tab for more key features

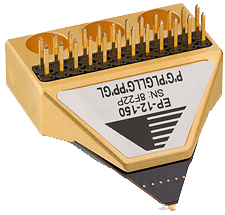

- High performance power bypassing provides low-impedance and resonant-free connections to 20 GHz

- RF bandwidth to 500 MHz

- Long probe life: > 250,000 contacts

- Beryllium-copper tips for gold pads or tungsten for aluminum pads

- Oscillation-free testing of wide-bandwidth analog circuits

- Use with ACP series probes to provide functional at-speed testing for known-good-die

- Mix multiple contact types: Ground, Power (Standard or Eye-Pass), Logic/Signal

- Low and repeatable contact resistance on aluminum pads ( < 0.25 Ω on Al, < 0.01 Ω on Au)

-

Ease of use – Less experienced operators can perform DC measurements by simply pushing a button. This reduces the need of experienced users full time on each system.

-

Reduced Soak Time – The system will automatically re-align the probes to the pads if they drift from alignment. This reduces test time and increases throughput.

-

Unattended Use – Measurements can be left running over night or the weekend, testing all devices on the wafer, and at different temperatures without the need of an operator.

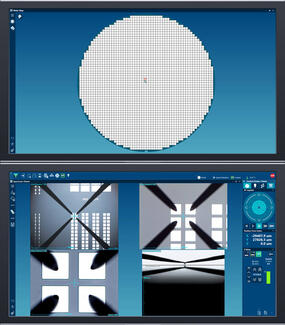

Floating Action Buttons

- Easy and fast setup of camera views

- Go to Light and Image Settings of the selected camera view with only one mouse click

Workflow Wizard

- Guided workflows for wafer setups, alignment tools and Autonomous Assistants

- Workflow wizard shows task-relevant settings and options only

- Wizard settings can be corrected anytime – no need to restart the wizard

- Wizard helps with intelligent solutions in case of error

See "Specifications & Details" tab for more key features

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.