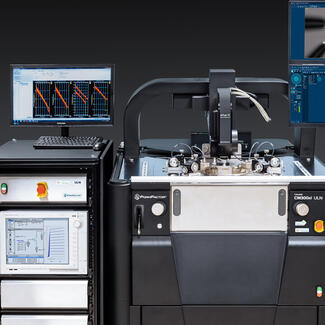

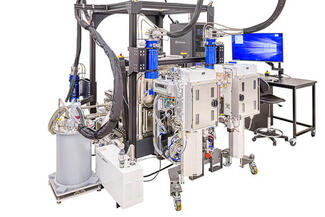

FormFactor - Cascade CM300xi - 300 mm semi-/ fully-automated probe system

Flexibility

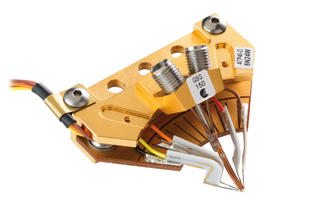

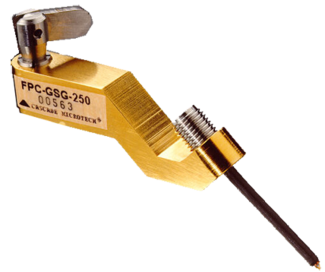

- DC, AC and RF/microwave device characterization, 1/f, WLR, FA and design debug

- Full thermal range of -60°C to +300°C

- Compatible with TopHat or IceShield

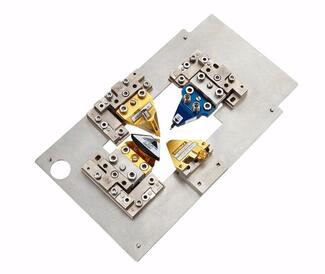

- Usage of manual and motorized positioners, probe cards within EMI-shielded environment

- Upgrade path to meet your future needs

- Stable and repeatable measurements over a wide thermal range

High accuracy and repeatability

- Reliable and repeatable contact

- Moisture-free, light-tight and EMI-shielded test environment with MicroChamber® technology

- Advanced EMI-shielding with PureLine and AttoGuard technologies available

- Superior low-leakage and low-noise measurements

- Safe and accurate hands-off testing

- Minimizes settling times for efficient measurements over full thermal range

See "Specifications & Details" tab for more key features

Best-in-class measurement performance at a high level of automation in the lab*

The CM300xi probe station meets the measurement challenges brought on by extremely complex environments, such as unattended testing on small pads over time and at multiple temperatures. Best-in-class measurement performance is achieved for a wide range of applications in an EMI-shielded, light-tight and moisture-free test environment. Thermal management enhancements and lab automation capabilities result in improved yields and faster time to data. For cold temperature testing, FormFactor’s open IceShield™ environment is also available for the CM300xi.

The CM300xi supports Contact Intelligence™ – a unique technology which enables autonomous semiconductor test. A powerful combination of innovative system design and state-of-the-art image processing provides an operator-independent solution to achieve highly-reliable measurement data at any time and temperature.

With the material handling unit, the CM300xi probe station combines fully-automated wafer test with highest accuracy and flexibility. The system can handle up to fifty 200 or 300 mm wafers provided in SEMI-standard wafer cassettes.

The optional ReAlign™ feature offers the capability to perform “off-axis” probe to pad alignment independent from the main eVue microscope. ReAlign is the ideal tool for probe cards that do not allow viewing pads and probe tips from above. This is the case e.g. for vertical and Pyramid probe cards. The ReAlign hardware includes 2 additional cameras: the downward looking “Platen Camera” is directly integrated into the platen of the CM300xi and is used for observation of the pads; the upward looking “ChuckView Camera” is used for characterization of the probe tips. The Realign wizard allows easy and fast setup with predefined algorithms for different probe cards like Pyramid, Apollo, Cantilever, etc. ReAlign can automatically manage temperature transitions without the need for operator intervention.

Applications

- Failure Analysis

- IV/CV

- Reliability

- RF/mmW/THz

Easy manual wafer loading

- Chuck mounted on rollout stage that can be opened manually

- Enables full access to the chuck and the auxiliary sites

- For fast and safe manual loading and unloading of wafers

3D Manual Controls

- Virtual Platen Lift and XY knobs at front

- Intuitive, and precise movement of chuck in X, Y, and Z-direction

- Platen Lift enables extremely rapid and intuitive way in performing many alignment tasks like setting up the contact height

Contact Intelligence Technology

- High thermal stability components

- On-axis probe-to-pad alignment

- Automated temperature ramp

- Soak time management

- Enables CM300xi to sense, learn and react to multiple temperatures and small pad layouts

- Provides the most accurate probe to pad alignment

Thermal Measurements

- Wide range of extremly performant, reliable thermal chuck systems from ATT

- Flexibility from hot only to full thermal range of -60°C to +300°C

- Up to 25% lower air consumption (CDA) than other systems in the market (300l/min) with no compromise in transition times

- Up to 15% faster transition times than other systems in the market

- Patented MicroVac™ and FemtoGuard™ Technologies, providing ultra-low noise measurements and controlled leakage, low residual capacitance for repeatability and advanced measurement accuracy and speed

- Field-upgradeable: grows with your needs

Automated test

- Thermally induced drift can be automatically re-aligned for 30 μm pads in a temperature range from -40°C to 150°C (the effective temperature range depends on pad size, probe card holder and probe card)

- Enables unattended tests on small pads down to 30 μm over time and at multiple temperatures

- Faster time to data

Modular design

- 3 performance level configurations (fully-shielded / shielded / open)

- Many options to suit your budget / test needs

Choose now or upgrade later in the field:

- PTPA option with chuck and platen camera

- 3 automation levels: Semi-automated, Fully-automated, Dual systems

- Non-thermal, hot-only and full-thermal range from -60°C to 300°C

Test Productivity and Material Handling Unit

- Test automation out-of-cassette for higher test cell efficiency for over-night/over-weekend operation

- Handles up to 25/50 wafers (200 or 300 mm)

- SEMI-standard cassette hot-swap capability

- Safe wafer handling without operator attendance

- MHU301: Very compact fully-automated solution with low footprint

- MHU300: Upgradable in the field to dual-prober system

- Fast delivery of a wide variety of precise model parameters

- Accelerated process and device development

Velox Probe Station Control Software

- User-centered design minimizes training costs and enhances efficiency

- Windows 10 compatibility enables highest performance and safe operation with state-of-the-art hardware

- Comprehensive alignment functions – from simple wafer alignment and mapping to advanced probe-to-pad alignment over multiple temperatures for autonomous semiconductor test

- Simplified operation for inexperienced users: Reduced training costs with Workflow Guide and condensed graphical user interface

- Loader integration – Easy creation of workflows and receipts and no need for any additional software

- VeloxPro option: SEMI E95-compliant test executive software that enables simplified and safe automation of the entire wafer test cycle

Velox Dash™

- Modern User Interface with Touch Screen: Convenient probe station operation with just a touch of a finger

- Access to Most Common Probe Station Functionalities: Fast and efficient probe station operation

- Intuitive and Customizable to Operator’s Needs: Simplified operation, even for inexperienced users

- Integrated Solution: Replaces mechanical joystick and eVue remote control

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.