FormFactor - Cascade DCP-HTR Series Probe - High-performance DC parametric probe

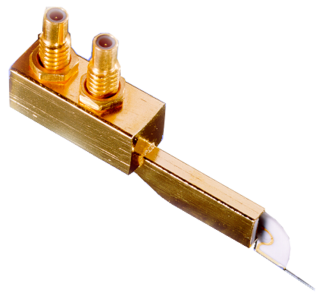

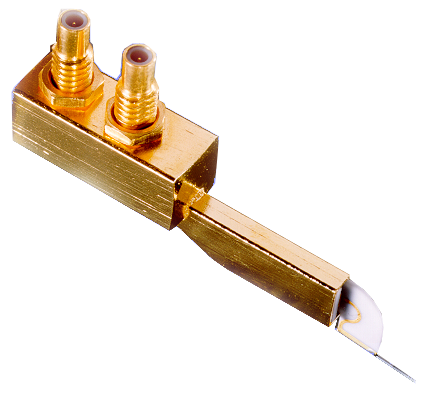

- Ultra-low, fA-level current and fF-level capacitance measurements from -65 °C to + 300 °C

- Guarantees fully-guarded measurements to fA and fF levels

- Individual connectors provide force-sense connection for quasi-Kelvin and CV measurements

- Allows probing of different pad materials and sizes

- Fast replacement of worn probes without the need for tools

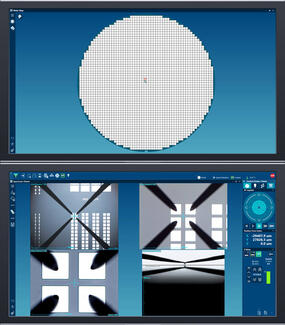

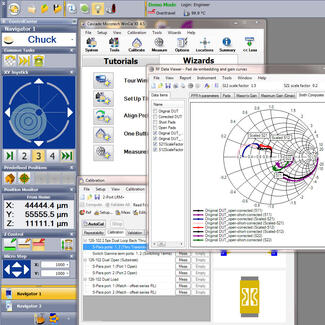

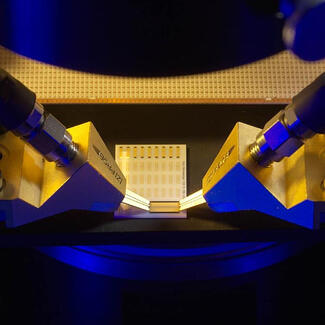

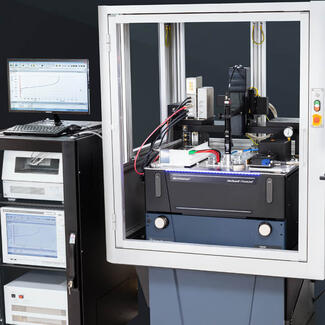

The DCP-HTR probe delivers fA-level measurement capability from -65 °C to 300 °C for advanced characterization and reliability testing. Its unique design offers superior guarding and shielding over-temperature, overcoming the high-temperature performance limitations of standard coaxial needles. When used on a probe station with a MicroChamber, the DCP-HTR allows full utilization of semiconductor parametric test instruments. The optional probe tips with small diameter are ideal for probing pads as small as 30 x 30 μm.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.