FormFactor - Cascade Multi-|Z| Probe - Test Up to 16 RF Signals with One Probe

- Ideal for multiport RF/Microwave and high-speed digital signal testing

- Mix DC and RF/Microwave signals on one probe

- Long lifetime – typically over one million (1,000,000) touchdowns

- Excellent performance in temperatures ranging from 10 K to 200°C

- Probe on any pad material with no damage

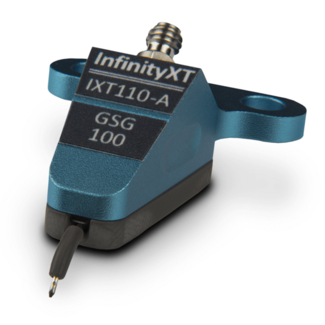

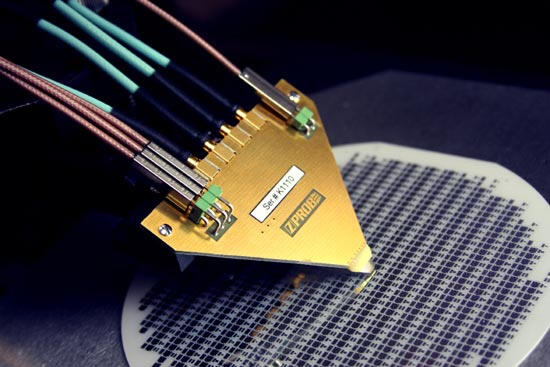

The Multi |Z| Probe® is a new dimension in RF/microwave multiport and digital signal testing. It uses the same patented technology as other |Z| Probes, but can carry up to 16 RF/microwave signals on one probe. Additionally, DC and RF/microwaves signals can be mixed on the probe, allowing you to add power biasing along with RF signals.

When several individual pads must be contacted by a single probe, it is extremely important that the contact structures are perfectly aligned. Thanks to the MEMS technology used, the Multi |Z| Probe can contact up to 35 pads. Furthermore, small variances in pad height, are easily overcome by the spring-like movement of the independent contacts.

The Multi |Z| Probe can be configured to test DC signals for your DC-test applications if necessary. For single-ended applications, please see the |Z| Probe. For applications requiring just two signals, the Dual |Z| Probe is available. The Multi |Z| Probe can also be integrated into the |Z| Probe Card for high-throughput RF testing.

More Product Information

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.