FormFactor - Cascade Light Wave Probe - Multi-configurable optical probe for photonic device characterization

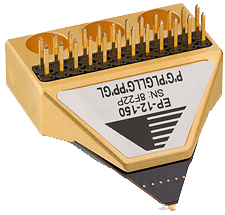

The LWP series Lightwave Probe enables optical measurements for on-wafer and hybrid photonics devices. It features user replaceable fiber pigtails allowing the probe to be optimized for a variety of light delivery and light collection applications including the characterization of topside illuminated photodiodes, Vertical Cavity Surface Emitting Lasers (VCSELs), hybrid transmitters and receivers, and LEDs.

More Product Information

- This DCS Series Controller provides Lighting Control Flexibility in a slim 112 mm x 124 mm x 23 mm package.

- Plug-n-Play compatibility with Ai lighting Products, featuring SignaTech™ technology.

- Seamless switching from continuous-on to gated on/off and strobe overdrive; 3 independently configurable trigger inputs.

- Din-rail mount, UL 508a Panel listed and GUI, Web Browser or command line setup and control tools, SDK.

- 1 output, 3 channels – designed to drive multi-channel RGB / segment lights, as well as single higher current draw lights.

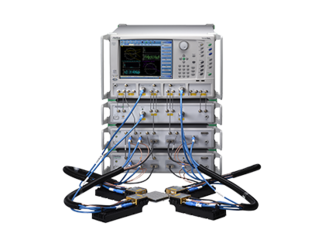

The VectorStar ME7838x4 broadband system VNA offers the widest available 4-port single sweep measurements from 70 kHz to 110, 125, 145, and 150 GHz with mmWave bands up to 1.1 THz

- The ME7838E4X 4-port system sweeps from 70 kHz to 110 GHz (Guaranteed specifications)

- The ME7838A4X 4-port system sweeps from 70 kHz to 125 GHz (Guaranteed specifications)

- The ME7838D4 4-port system sweeps from 70 kHz to 145/150 GHz

- The ME7838G4 4-port system sweeps from 70 kHz to 220 GHz

- All systems may be configured to include banded millimeter-wave modules up to 1.1 THz

- Industry-best calibration and measurement stability: 0.1 dB vs 0.6 dB over 24 hrs

- All systems also supports the 3744x-Rx receiver for noise figure measurements to 125 GHz

- Compact, lightweight mmWave modules offer low cost installation with industry-best performance

-

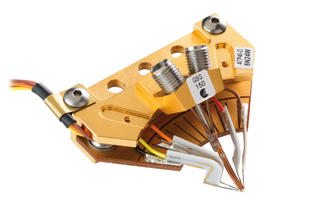

Combination of DC and RF in a single probe module: One dual probe or a maximum of three RF; a maximum of 9 DC standard (other quantities upon request).

-

Utilizes ACP tip design, GSG, GS or SG

-

RF tips available from DC to 110 GHz

-

Choice of BeCu or tungsten tips

-

DC power needles come standard with 100 pF microwave capacitor

-

Power bypass inductance: 8 nH

-

Maximum DC voltage: 50 V without power bypassing (25 V with standard power bypassing, and component dependent with custom power bypassing)

-

Ideal for probing the entire circuit for functional test

-

Dual ACP configuration supports differential signaling applications

-

DC probes can provide power or slow logic to circuit under test

- High performance power bypassing provides low-impedance and resonant-free connections to 20 GHz

- RF bandwidth to 500 MHz

- Long probe life: > 250,000 contacts

- Beryllium-copper tips for gold pads or tungsten for aluminum pads

- Oscillation-free testing of wide-bandwidth analog circuits

- Use with ACP series probes to provide functional at-speed testing for known-good-die

- Mix multiple contact types: Ground, Power (Standard or Eye-Pass), Logic/Signal

- Low and repeatable contact resistance on aluminum pads ( < 0.25 Ω on Al, < 0.01 Ω on Au)

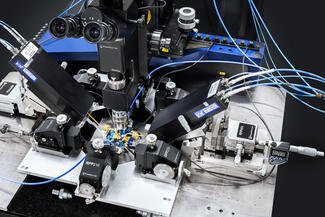

DC, RF and Optical Probe Positioning for Highest Accuracy Measurements

FormFactor offers a wide variety of manual and motorized probe positioners for any application from DC to terahertz measurements and beyond.

With their radial and flat incoming light, LUMIMAX® LED Dark Field Illuminations are the preferred option for inspecting surfaces. Their special light guide means that this LED Dark Field Illumination geometry can be used to show edges, cavities and other surface defects in high contrast.

The Dark Field Lights in the DFL series are available in several sizes for continuous and strobe mode.

Integrated controllers, powerful LEDs and standardised LUMIMAX® connections guarantee simple and stable integration of the LED Dark Field Illumination into the system environment.

TM MAESTRO provides a comprehensive and centralized solution for monitoring and controlling telemetry infrastructure worldwide.

Designed to meet the critical needs of telemetry operators, this software offers a user-configurable GUI that adapts to various user profiles and mission phases, from preparation to live flight tests and station maintenance. TM MAESTRO is scalable and easily accommodates new telemetry equipment, allowing for the addition of an unlimited number of components, from antennas to decommutators, making it a highly flexible system.

- Flight Qualified

- Support for IEEE-1588 and GPS Havequick II I/O

- Input IEEE-1588 and Convert to IRIG A/B

- Tested to MIL-STD 810F and 461E CE102 and RE 102

- Custom options available

With their domed shape, LUMIMAX® LED dome lights generate a diffused light that falls on the test object from all directions, achieving completely shadow-free illumination.

Typical applications are the inspection of reflective or mirroring materials. With a LED dome light, even complex or curved surfaces can be illuminated homogeneously.

LED dome lights are extremely well suited for standard-compliant reading and verification of two-dimensional codes.

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.