ProjectionWorks

Delta Sigma Company began operations in January of 1990 in Hesperia, California. In July of 1997, we moved to Kennesaw, Georgia to be closer to the F-22 Raptor team. We have over 40 years worth of experience in-house for all kinds of specialized LO (low observables) testing. We have built everything from the antenna to the cal target, radar, data collection & processing software, RF section, pylon elevator, pylon, multi-axis target positioner, target, and motion controls for moving parts in/on the target.

In 2010, the first ProjectionWorks System was installed. We primarily focus on developing complex automated systems to replace manual aircraft manufacturing stations and eliminate bottlenecks in station cycle time. We understand machine vision, lasers, servos, precision motion control, and dozens of other technologies that can be applied to aircraft manufacturing. At DSC, we engineer all of our own designs and software and build all of our machines in-house from the ground up, resulting in a fully 100% custom automation solution for the customer.

Contact Details

ProjectionWorks, a DeltaSigma Company

2125 Barrett Park Dr., #110, Kennesaw, GA 30144, USA

Phone: 770-575-5100

Email: info@deltasigmacompany.com

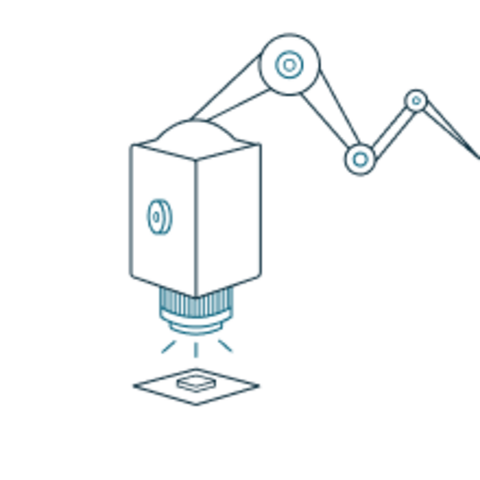

Imaging/Machine Vision

Products

-

Mechanical Assembly – provides assembly and inspection instructions

-

Paint Masking – provides paint scheme viewing and masking instructions

-

Measurement Assistance – provides data input from a GripGage™to user application software

-

Wire Harness Assembly – provides wire harness assembly instructions

-

Kit Preparation – provides kit presentation for nested cut/stamped material