AVT - Custom Solutions

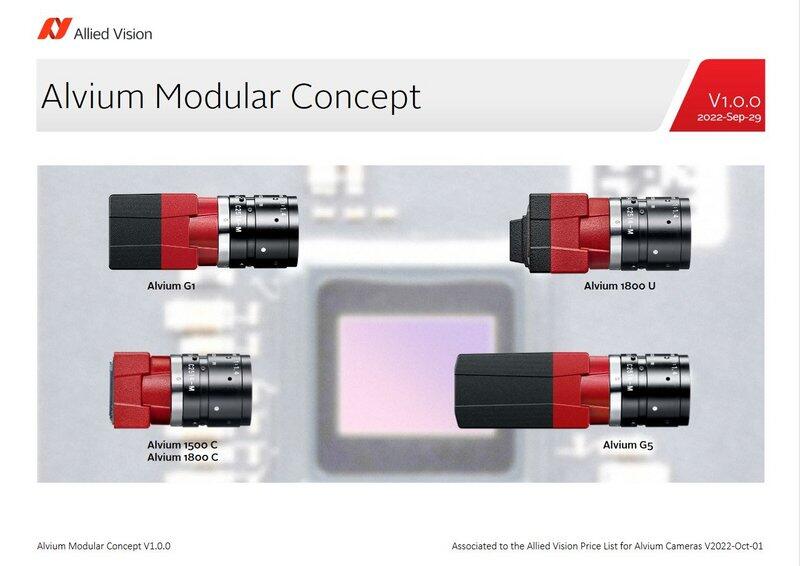

The Alvium camera platform offers a variety of hardware options for Alvium GigE Vision, 5GigE Vision, USB3 Vision, and CSI-2 cameras. In addition to the wide choice of camera models the Alvium Modular Concept includes:

- Filter options (IR cut filter)

- Sensors without cover glass (Taped Cover Glass, Removed Cover Glass)

- Black housing

The versatile Manta cameras include optional alternative designs or components as part of the Allied Vision Modular Concept.

- Angled-head orientations

- medical housing

- board-level versions

- optical filters

- removed sensor cover glass

You would be surprised that the most common modifications you may be thinking of have already been anticipated. That means they are available at affordable prices and within short delays.

Check our Modular Concept document or ask your Sales representative for advice!

Adapting our cameras to your needs

Even if your specifications cannot be met using the Allied Vision Modular Concept, our engineers make sure the camera adapts to your application. Tell us the hardware or firmware modifications you need – whether a special housing, a different interface architecture, specific triggering functionalities or whatever specific requirements you may have. Modifying cameras is what Allied Vision started from back in the 1990's. We have that know-how in our genes!

Your tailor-made camera

If what you need is to design your own camera from scratch, Allied Vision is your partner of choice. Our R&D departments in Germany and Canada are experienced in managing complex development projects for demanding OEM customers worldwide. Applications include 3D scanning, automotive manufacturing, medical equipment and many more.

More Product Information

Allied Vision Technologies

Firewire, Gigabit Ethernet and Camera Link Cameras