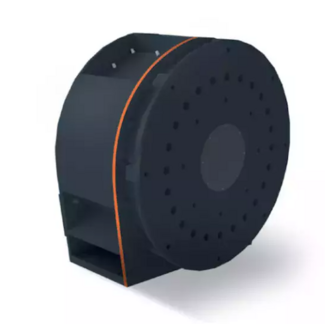

MVG - Rotary Positioners - Polarization Positioners: Heavy Duty

The MVG-Orbit/FR Legacy Series Polarization Positioners provide accurate, balanced rotation, and controllable velocity for the positioning of very large devices in test configurations. Their rugged yet straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio.

|

Key Features |

|---|

|

Operating Loads up to 33,000 lbs (14,970 kg) |

|

Turntable Diameter up to 48.0 in (1,219 mm) |

|

Excellent Angular Position Accuracy |

|

Low Backlash Design |

|

Precision Bearings |

|

Closed Loop Servo Control |

|

Industry-Standard Wiring |

|

Tachometers for Optimum Speed Regulation & Control |

|

Wide Operating Temperature Range: - 4° F to 140° F (- 20° C to 60° C) |

|

Fully Enclosed Design of Drive Gear Train & Data Take-Off |

|

Wide Variety of Available Options |

|

Applications |

|---|

|

General Purpose Positioning Subsystems |

|

Far-Field & Near-Field Antenna Measurements |

|

Indoor & Outdoor Use |

|

Industries |

|---|

|

Solutions for Academic & Research Institutes |

|

Solutions for Aerospace & Defense |

More Product Information

These MVG-Orbit/FR Legacy Series EL/AZ Positioners provide accurate, balanced rotation, and controllable velocity of 2 axes, for the positioning of very large devices in test configurations.

Their rugged yet straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio.

Typically, the unit includes the body, precise slew bearings, a DC motor, gear reducer, encoder/synchro, and limit switch assembly. The turntable surface is designed with a threaded mounting hole pattern for ease of use. A Safe/Operate switch is included to ensure safety.

The LCU AL-4189 - Local Control Unit is a hand-held control box specifically designed and built to be used in conjunction with ORBIT/FR controllers and PCU’s. It provides the attendant (operator, serviceman etc.) with a high degree of flexibility in operating the system elements.

The MVG-Orbit/FR Legacy Series Polarization Positioners provide accurate, balanced rotation, and controllable velocity for the positioning of very large devices in test configurations. Their rugged yet straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio.

The AL-4188 series LCUs are portable, wireless hand-held units that are connected to a PCU/positioner controller via a wireless RF link. These LCUs utilize the PCU/ controller’s basic control, limit and supply circuits. They incorporate a rotary switch for axis selection, limit indicators, and a potentiometer for speed and direction control.

The MVG-Orbit/FR Legacy Series Polarization Positioners provide accurate, balanced rotation, and controllable velocity for the positioning of devices in test configurations. Their sturdy and straight-forward construction ensures maximum reliability and trouble-free operation, yielding the best size and weight/performance ratio.Turntable diameters up to 30.0 in (762 mm) .

AL-48000 model towers are suited for medium duty applications with an operating load of up to 1,000 lbs (455 kg). This series is available with either a manual hand-wheel or motorized linear offset slide. The mast (vertical or inclined) is available in fiberglass or aluminum construction.

The EH1840 EMC horn combines stable gain performance and low VSWR with wide band frequency operation. The horn is single linearly polarized with excellent cross-polar discrimination. The unique horn design suppresses any possible excitation of higher order modes in the aperture and maintains a well-defined smooth radiation pattern in the direction of the boresight axis throughout the operational bandwidth.

MVG medium duty azimuth positioners provide accurate rotation, velocity, and direction and offer turntable diameters up to 30 in (686 mm). Rugged yet simple construction ensures maximum reliability and trouble-free operation.

- Multiple voltage⁄current ranges

- Direct numeric entry and incremental rotary control of voltage and current

- The remote or local sense

- Illuminated keys and display legends.

- Up to ten store/recall set-ups (30 setups for triple output)

- Power output display

- Link and copy mode

Microwave Vision Group (MVG)

Testing Connectivity for a Wireless World

The Microwave Vision Group offers cutting-edge technologies for the visualization of electromagnetic waves. With advanced test solutions for antenna characterization, radar signature evaluation and electromagnetic measurements, we support company R&D teams in their drive to innovate and boost product development.

Contact Details

Microwave Vision Group

1320 Air Wing Rd, Suite 101, San Diego, CA 92154, USA

Phone: 678-797-9172

Test & Measurement