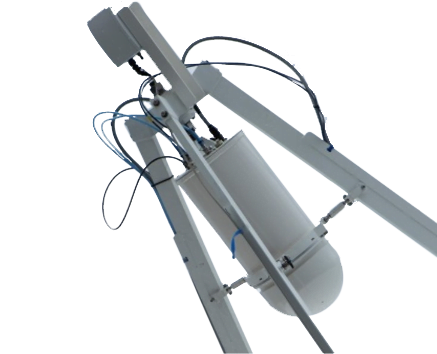

Safran DSI - Tri-Band Feed L/S/C Tri-Band Feeds for Antenna Dishes from 6 to 24 ft

Our patented miniaturized L/S/C Tri-Band Feed delivers top-notch performance and unmatched flexibility.

Equipped with a common L/S/C radiating front end, it’s complemented by a modular set of active RF modules, enabling simultaneous reception and tracking across various frequency bands. Its compact, lightweight design allows it to be mounted on any dishes ranging from 6 to 24 feet.

Available in single, dual, or tri-band configurations, this feed offers the best value for customers looking to meet current requirements while staying future-ready.

It’s also field-upgradable to add any missing bands with straightforward RF module additions, ensuring scalability while keeping costs in check.

FROM ONE FEED TO A COMPREHENSIVE TELEMETRY GROUND STATION

Opt for a comprehensive global telemetry solution that includes not only feeds but also telemetry antennas and advanced receivers for a seamless and integrated communication experience:

Tri-Band Feed Features

|

LTE/4G Mitigation |

LTE/4G, WCS & Customized Rejection Filters (Upgradable During Antenna Lifetime) |

|---|---|

|

SCM 1000 HZ Scan Rate |

Highest Accuracy of Tracking |

|

Modular L – S or C-Band |

Simple Add-On upgrade without any Structural Change |

|

Seamless Prime Focus Integration |

Tri-Band even with Dishes as Small as 6’/1.8m |

|

No RF-Band Compromise |

Concentric 3-Band Feed, without need of Dichroic Filter |

More Product Information

Safran DSI

Safran Defense & Space, Inc. (Safran DSI) is a leading provider of cutting-edge solutions designed to address the evolving challenges of national defense and advanced space missions. Headquartered in Arlington, Virginia, Safran DSI operates through specialized business units in Optronics, Space Solutions, Testing & Telemetry, Geospatial Artificial Intelligence (AI), and Assured Positioning, Navigation, and Timing (PNT).