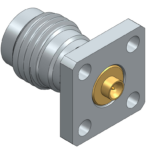

Southwest Microwave - 0.8 mm Connectors - DC to 145 GHz

Introducing Southwest Microwave’s newest high-performance connector, the groundbreaking 0.8 mm (145 GHz) high-performance thread-in connector. This cutting-edge design ensures exceptional signal integrity while delivering the industry’s lowest VSWR, RF leakage, and insertion loss.

- Will mate with IEEE 287 & IEC 61169-64 standards

- DC to 145 GHz

- Field replaceable and reusable

More Product Information

-

Auto gain (manual gain control: 0 to 26 dB; 1 dB increments)

-

Auto exposure (18 µs to 126 s; 1 µs increments)

-

Black level (offset)

-

Decimation

-

Gamma correction

-

Three look-up tables (LUTs)

-

Pixel defect masking

-

Piecewise Linear HDR mode

-

Region of interest (ROI), separate ROI for auto features

-

Reverse X/Y

-

Auto-iris (video type)

-

Event channel

-

Image chunk data

-

IEEE 1588 Precision Time Protocol (PTP)

-

Storable user sets

-

StreamBytesPerSecond (bandwidth control)

-

Stream hold

-

Sync out modes: Trigger ready, input, exposing, readout, imaging, strobe, GPO

-

Temperature monitoring (main board)

-

Trigger over Ethernet (ToE) Action Commands

- Combine up to 16 SPDT or 8 multiport, high-performance relays in a 2U footprint

- Latching/Terminated options (EX7204L)

- LXI/LAN and USB command and control options

- Embedded web interface provides interactive utility to monitor and control relays from anywhere in the world

- Flexible API supports IVI and Linux development environments minimizing software investment

- LXI trigger event implementation provides seamless test synchronization with external devices

- Store up to 128 relay configurations for quick recall, including automatic power-up state

Southwest Microwave connectors and accessories are designed to be compatible with each other to assure electrical performance. Southwest Microwave cannot assure electrical performance when the accessories are used with a non-Southwest Microwave connector.

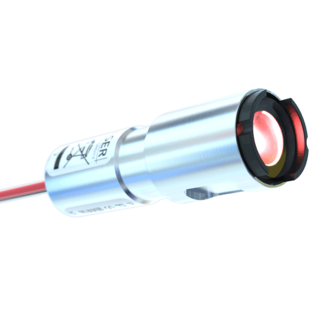

- Repeatable high product quality due to automated production processes

- Highest reproducibility of beam quality

- Optical output power up to 40 mW

- Wavelengths from 640 nm - 685 nm

- Fixed focus

- IP 50 (optional IP 67)

The ZX10 is a compact high-performance laser module developed for industrial image processing applications. In automated production, a 14-axis robot precisely aligns all optical components, resulting in exceptional beam quality with a boresight error of less than 0.8 mrad. Depending on the application, the laser is available in red or infrared wavelengths and can be flexibly adapted to customer-specific requirements. With its rugged industrial design and high power stability, the ZX10 is particularly suited for use in sensors, testing devices, and machinery. Setting new benchmarks in precision and reliability, it is a trusted choice for advanced machine vision systems.

Southwest Microwave offers a broad family of SSBP multi-coax contacts and assemblies to address RF/microwave packaging miniaturization and flexibility challenges. These push-on coax contacts simplify interconnections and cabling while offering greater system reliability than the alternative of mating a large array of standard coax connectors. These SSBP coax contacts were designed to fit into standard off-the-shelf MIL-DLT-38999 and MIL-DTL-24308 D-Sub connectors and are interchangeable with standard signal contacts available in 20 HD, 20, 16, 12, 8 sizes to accommodate a variety of performance requirements.

Contact us for flexible cable assemblies and harnesses for OTS MIL-DTL-38999 series I, II, III, and IV or MIL-DTL-24308 D-sub connectors. All size 20 contacts are sold on cables.

The SM7000 Series microwave switching modules are members of the VXI Technology SMIPII™ family. They offer a modular design allowing custom switching configurations to be easily assembled and modified in the field.

The SM7000 is a single-wide, C-size VXI module, which can support up to six different microwave switches including: a dual SPDT; SP3T through SP6T; transfer switches and passthrough adapters that allow the module to control up to eight externally mounted relays each.

See "Specifications & Details" tab for more information.

-

Auto gain (manual gain control: 0 to 22 dB)

-

Auto exposure (manual exposure control: 100 µs to 1 s, 1 µs increments)

-

Binning (horizontal and vertical) (sum)

-

Decimation X/Y

-

Enhanced Defect Pixel Correction (DPC)

-

Fixed Pattern Noise Correction (FPNC)

-

Gamma correction

-

Three look-up tables (LUTs)

-

Region of interest (ROI)

-

EF lens control (order option -18)

-

Event channel

-

Image chunk data

-

IEEE 1588 Precision Time Protocol (PTP)

-

RS232

-

Storable user sets

-

StreamBytesPerSecond (bandwidth control)

-

Stream hold

-

Sync out modes: Trigger ready, input, exposing, readout, imaging, strobe, GPO

-

Temperature monitoring (main board and sensor board)

-

Trigger over Ethernet (ToE) Action Commands

SuperMini Board-to-Board solutions optimize interconnect performance for board-to-board stacking applications.

Available bullets enable board-to-board spacing as close as 3 mm, assuring transmission line dependability for tightly stacked PCBs. Low mating insertion force allows for an increased density of interconnections per board. Unique bullet design enables extended mating and de-mating cycles.

Southwest Microwave

Since 1981, Southwest Microwave has delivered performance-leading interconnect solutions currently available from DC to 110 GHz for hi-rel/space, defense, instrumentation, integrated-circuit and PCB evaluation applications. Built in the USA to rigorous performance and quality standards, Southwest Microwave connectors deliver the industry’s lowest RF leakage, insertion loss and VSWR.