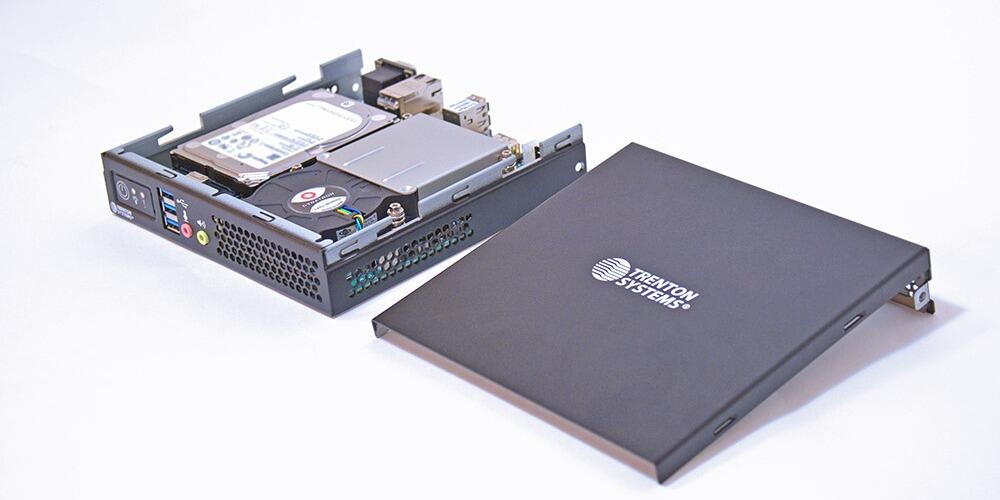

Trenton Systems - ION Mini PCs

Small form factor rugged mini PCs designed in secure, compact enclosures to enhance performance and adaptability alongside evolving workloads. ION Mini PCs are designed to enhance performance, scalability, and security for the most complex application and program demands.

- Harsh-environment Protection - All key components are stress-tested to pass stringent military standards, ensuring stability in harsh environments.

- Server-class Features - A Mini PC powerhouse with server-class specs like IPMI for remote management and virtualization for increased flexibility and scalability.

- Full Control & Customization - Our in-house software engineers can tweak BIOS source code to bolster firmware security and meet your exact needs.

Minimum Footprint. Maximum Compute Power.

Virtualization technologies allow you to run multiple accelerated workloads on a single piece of hardware while optimizing resource usage and reducing total cost of ownership.

Server-Class Technologies

ION Mini PCs are designed to enhance performance, scalability, and security for the most complex application and program demands.

Optane MemoryPersonalized, accelerated computing that keeps often-used applications and documents ready for quick access. |

Turbo BoostAlternate between low and high CPU clock speeds based on workload requirements within diverse data environments. |

vPROPerformance, security, and management enhancements that minimize disruption, reduce costs, and help thwart cyberattacks. |

Technical Highlights

- Single Intel® Core® CPU

- 2x DIMM Slots

- Up to 2x SSDs

- 1x IPMI Port

- 6x USB Ports

More Product Information

Trenton Systems

Founded in 1989, Trenton Systems provides the defense, government, industrial, and commercial markets with advanced, TAA-compliant high-performance computing solutions designed in consultation with customers. Equipped with the latest processing, AI/ML/DL, networking, security, and storage technologies, our solutions are designed in collaboration with our global partnership ecosystem.