-

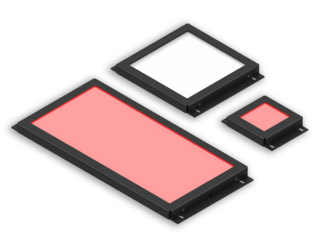

Part of the MicroBrite™ family of high performance, compact machine vision lights.

-

The edge-lit design provides the highest flux density of any backlight in our portfolio.

-

Ultra-thin profile for installations with demanding space limitations.

-

Available in 3 sizes with a multitude of available wavelengths.

-

Base Model numbers include BT050050, BT200100, BT100100

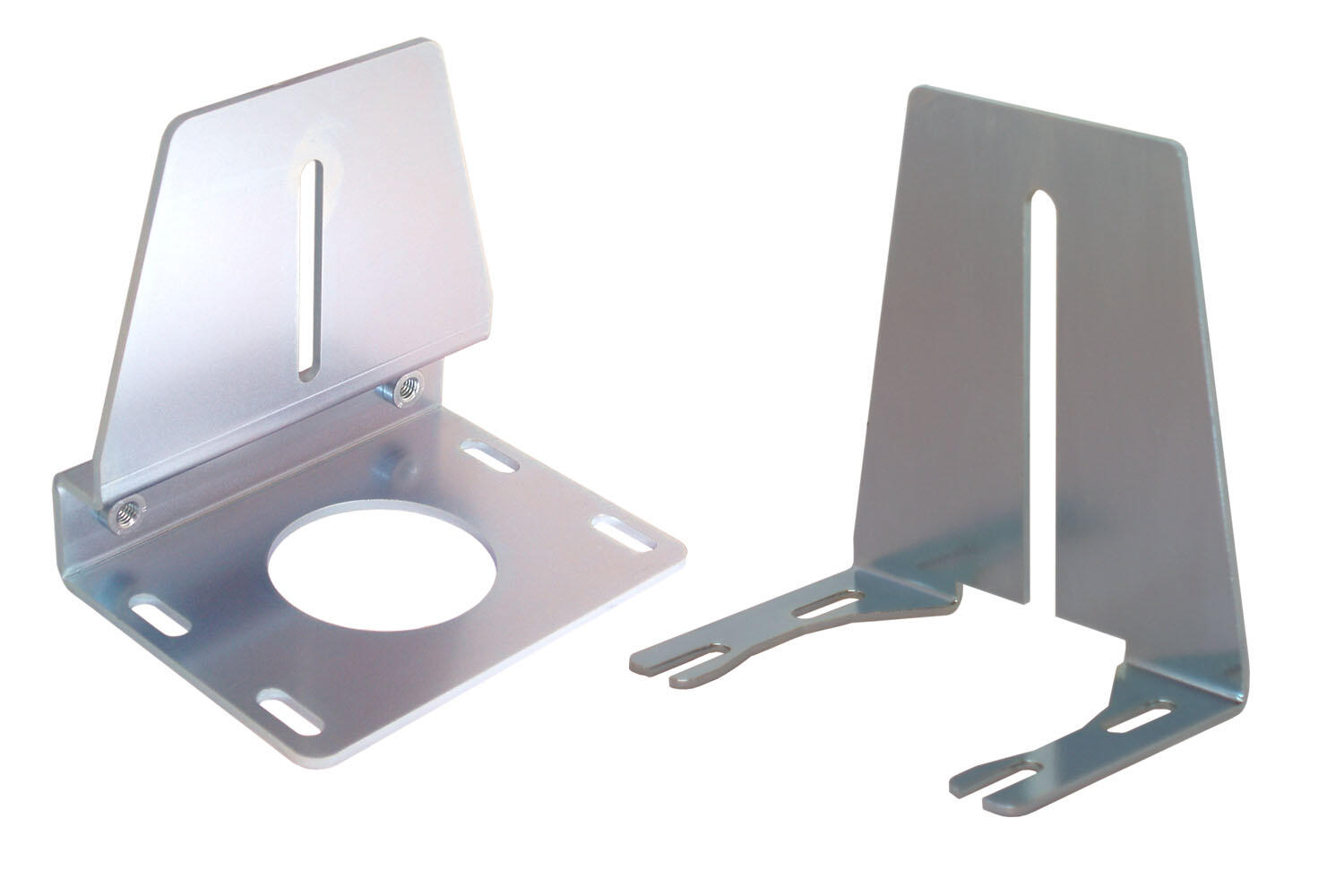

Advanced Illumination - Mounting Brackets

- To simplify the mounting process, Ai offers a line of camera brackets for positioning lights under or around the camera lens.

- Most brackets are designed to be held in place by the same screw that secures the camera.

General Specs

|

SKU's |

LB101, LB102, LB103, LB104, LB105, LB106, LB107, LB108, LB109, LB110 |

|---|

Compatibility Matrix

Part Number Key

More Product Information

-

IMX265 CMOS sensor

-

ALVIUM image processing

-

USB3 Vision

-

Various hardware options

-

Monochrome (1800 U-319m) and color (1800 U-319c) models

-

ALVIUM® Technology for on-board image processing

-

USB3 Vision interface for GenICam SFNC features

-

Platform concept that enables the operation of different Alvium camera models with a common software

-

Micro-B USB 3.1 Gen 1 connector with screw locks for industrial applications

-

Precise sensor-to-lens mount alignment

-

Standard M3 mounting holes for top and bottom mounting, standard M2 mounting holes for front mounting

-

Industrial performance for both embedded and machine vision applications

- Guaranteed performance to 43.5 GHz with Extended K™ ports

- Ideal for testing RF and microwave devices, mmWave antennas, and other passive 5G components

- Fast sweep speed and wide dynamic range minimize test times and maximize throughput

- Excellent corrected directivity allows for less measurement uncertainty

- Time domain with time gating option grants easier and faster fault identification

- Industry-standard LAN interface for remote control is more robust than USB and faster than GPIB

- Standard removable hard drive provides additional security for military and government research users

- A common GUI and SCPI interface within the ShockLine family

- USB ports allow for easy connection to user-provided monitor, keyboard, and mouse

- Small 2U package makes for efficient use of rack space

- Universal Fixture Extraction (UFX) software option provides advanced de-embedding tools for test fixture extraction

-

Sony IMX273 CMOS sensor

-

Power over Ethernet option

-

Angled-head and board level variants

-

Video-iris lens control

-

Monochrome (G-158B) and color (G-158C) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

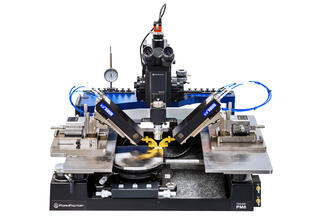

SlimVue Microscope

- Combined eye-pieces and CCD camera mount

- 3x zoom and quick lens exchange

- Quick lens exchange

- 1 um optical resolution

- Minimized scope footprint

- Fast change from navigation optics to high-resolution optics

- Resolving ‹ 50 μm pads

- Simple integration with any mmW modules

Application Specific Sigma Kits

- Engraved guides on mmW platen

- Supports broadband, load pull, coax RF and banded waveguide configuration

- Optical feedback on platen position (gauge)

- Adaptable to any mmW/sub-THz applications

- Seamless integration with any mmW modules and tuners

- Fast mounting and setup change

THz measurement capability

- Rock-solid mechanical design

- Submicron stage accuracy

- Optical feedback on platen and probe position (gauge)

- Motorized positioner

- <+-1 um separation repeatability

- Micrometer-accurate and repeatable probe placement and overtravel

- Highly-precise and stable THz measurements

- 6 GHz, 8 GHz, 18 GHz and 40 GHz RF Power Sensors

- Up to 195 MHz video bandwidth with 3 ns rise time

- Real-Time Power ProcessingTM technology with zero measurement dead time

- 100,000 measurements per second

- Power Analyzer Suite advanced measurement and analysis software

- Crest factor, CCDF and statistical measurements

- 10 GS/s effective sample rate

- 100 MS/s continuous sample rate

- Synchronized multi-channel measurements

-

Monochrome (G-033B) and color (G-033C) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba SDK and compatibility to the most popular third party image-processing libraries.

- This DCS Series Controller provides Lighting Control Flexibility in a compact 112 mm x 124 mm x 46 mm package.

- Plug-n-Play compatibility with Ai lighting Products, featuring SignaTech™ technology.

- Seamless switching from continuous-on to gated on/off and strobe overdrive; 3 independently configurable trigger inputs.

- Din-rail mount, UL 508a Panel listed and GUI, Web Browser or command line setup and control tools, SDK.

- 3 Independent Outputs – designed to up to 3 lights, synchronously or asynchronously.

-

Ultra-compact design

-

Affordable

-

Power over Ethernet

-

High frame rate

-

Monochrome (G-032B) and color (G-032C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Select between B 270 ASG protection glass and filter types: Jenofilt 217 IR cut filter, Hoya C-5000 IR cut filter, RG715 IR pass filter, or RG830 IR pass filterr

Advanced Illumination

Machine Vision Lighting Solutions