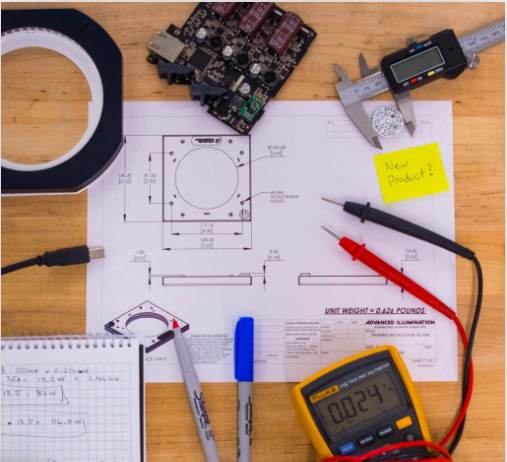

Advanced Illumination - Custom Products

Customers can leverage our multi-tier approach to customization to reduce engineering costs.

- Our adaptable Build-to-Order (BTO) system provides for very short lead times and allows a product to be configured from a large set of predetermined parameters, with hundreds of thousands of BTO combinations available. BTO products are indicated in the product data-sheet and are shipped within 1-3 weeks, depending on the product.

- Our Semi-Custom products require some additional design and documentation effort but can be a smart choice when more flexibility is required.

- Lastly, a full Custom product can be developed when your budget and time frame allows. This option supplies you with a fully custom-designed and built lighting solution that will be engineered to fit your exact machine vision needs.

Advanced illumination has provided custom LED lighting solutions to the Machine Vision Industry for over 25 years. Our reputation for design and engineering know-how can help you find the most precise and cost-effective solution.

We can consult with you to explore all these custom LED lighting solutions to propose which products and resources can provide you with the greatest ROI.

More Product Information

- S-parameters DC to 40 GHz, single-ended and mixed-mode

- Impedance Profile with <1 mm resolution, differential and common-mode

- Internal, automatic OSLT calibration

- USB-connected, small, lightweight

- Flexible display of the measurements

- Remove effects from fixtures, connectors and cables

- Emulate eye diagrams with CTLE, DFE and FFE equalization

- Advanced jitter analysis

- Solve machine vision applications efficiently by constructing flowcharts instead of writing program code, using field-proven tools for analyzing, classifying, locating, measuring, reading and verifying

- Use a single program for creating both application logic and operator interface

- Leverage deep learning for visual inspection through image classification and segmentation tools

- Rely on a common underlying vision library for the same results with an Iris GTX smart camera, vision systems or third-part computer

- Work with multiple cameras all within the same project or per project running concurrently and independently from one another, platform permitting

- Interface to Zebra AltiZ and third party 3D sensors to visualize, process and analyze depth maps and point clouds

- Communication options include discrete Zebra I/Os, RS-232, and Ethernet (TCP/IP, CC-Link IE Field Basic, EtherNet/IP, Modbus, OPC UA, and PROFINET, and native robot interfaces)

- Maximize productivity with instant feedback on image analysis and processing operations

- Receive immediate pertinent assistance through an integrated contextual guide

- Maintain control and independence through the ability to create custom flowchart steps

- Test communication with PLC using the built-in PLC interface emulator

- Protect against inappropriate changes with the Project Change Validator tool

- High dispersion for reflective surfaces and shorter working distances.

- Provides a narrower and less intense illumination area than the AL116.

- IP65 compliant washdown option is available, as are a wide spectrum of wavelengths.

- Available with polarization and diffusion light conditioning.

- This expandable compact bar light is pre-engineered for custom lengths in 2″ increments up to 40″.

- The Wide Linear Diffuse Light series is ideal for the inspection of elongated or cylindrical objects.

- Perfect for inspections requiring a multi-camera setup.

- Can be provided with up to 4 viewing ports.

- Expandable lengths from 6” – 36” (152 – 194mm) in 6” increments.

- The Pulsar 320E provides the ultimate in lighting control for strobe-only, high power applications.

- 2 outputs for controlling 2 lights independently, each capable of 50A @ 100V DC.

The laboratory and research industry faces unique challenges including long-standing, legacy pain points and frequently evolving needs. These include paramount safety and regulatory requirements for lab workers and patients alike, the need for high containment and sterility, and the integration of cutting-edge technologies. Complex and sensitive facilities require specialized testing solutions to ensure compliance, safety, and reliability. Effective planning and laboratory design and construction are crucial to creating environments that support advanced research and manufacturing processes, especially in the pharmaceutical and medical device sectors.

- Eliminating all but a narrow band of light (+/- 40nm) centered on the specified wavelength, band pass filters are used to enhance colors, or to stop unwanted ambient light from reaching the camera.

- Filtering can replace existing shrouds, simplifying the physical set up of an inspection site.

- Ai offers 660nm and 635nm band pass filters to fit a number of different lens sizes.

- The SL2420 is characterized as a Medium Aimed Spot Light.

- Precisely aimed LEDs provide a level of lighting control not found in traditional illuminators.

- A range of standoffs and fields of view may be specified at the time of order.

- The spot light is available in a wide range of wavelengths from UV to IR.

- Diffuser and polarizer options are also available.

- The SL2420 provides 10.1kLux at a working distance of 4” (100mm).

The SPARTE 300 series antenna is a battle-tested product that has consistently delivered top-tier performance for mission-critical applications where reliable telemetry reception is paramount. This rugged antenna guarantees our customers the utmost precision, a long operational life, and straightforward maintenance.

The SPARTE 300 series opens up a world of possibilities for users, ranging from aircraft tracking and high-speed target monitoring to duplex datalinks with both receiving and transmitting capabilities.

Furthermore, the extensive and customizable input/output options empower users to operate multiple antennas in a coordinated, multi-site tracking setup. With all antennas, regardless of size, being effortlessly monitored, managed and controlled by using our TM Maestro software.

Advanced Illumination

Machine Vision Lighting Solutions