Focus Microwaves - RAPID-VT Digital Tuners

-

Supports the latest 5G FR1 and IEEE 802.11ax standards

-

up to 1GHz active load pull bandwidth capability

-

Test the latest high bandwidth and high modulation cellular standards such as 1024QAM 802.11ax

-

This system can be used in all parts of the design cycle

-

-

Initial device characterisation

-

MMIC or PA design

-

Design verification testing

-

Product testing in the factory

-

-

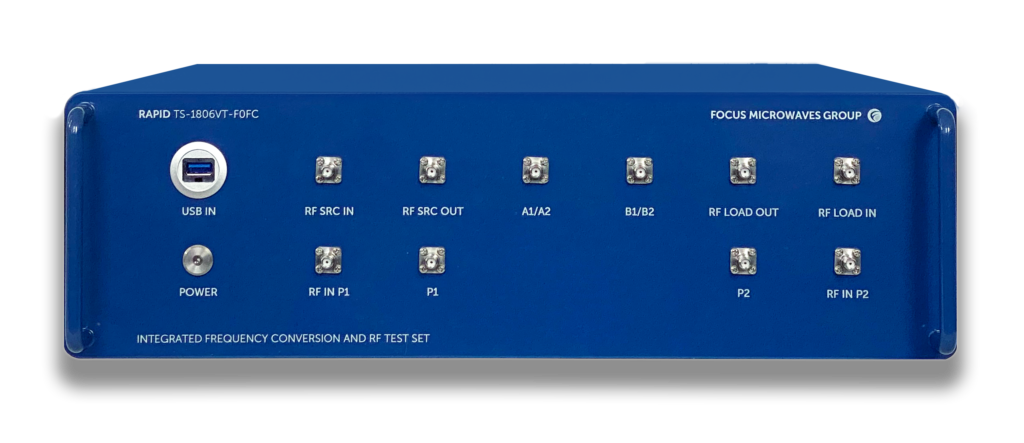

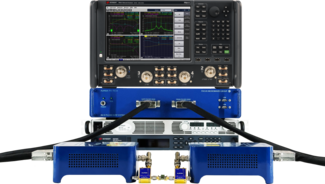

Focus Microwaves’ RAPID digital tuner technology is now available for very wideband communication signals, supporting the latest 5G FR1 and IEEE 802.11ax standards. This new architecture leverages the raw performance of National Instruments PXIe-5841* PXI Vector

Signal Transceiver.

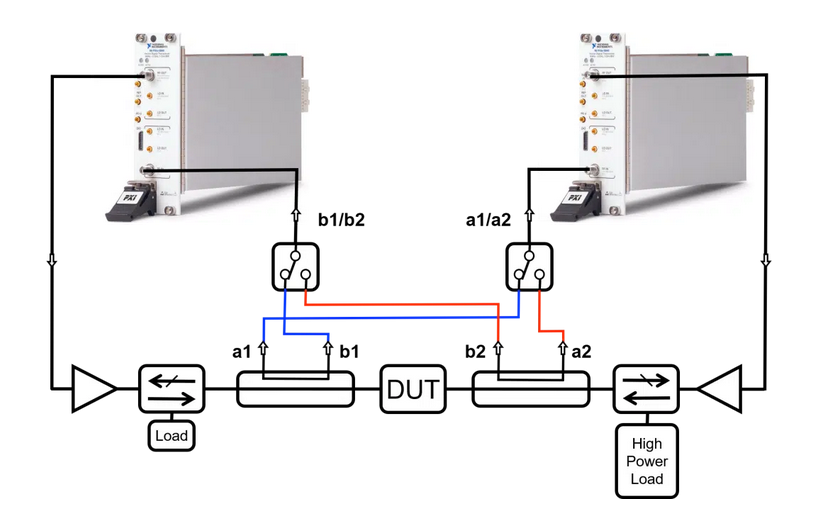

The Rapid VT, utilizes two PXIe-5841 VSTs to make a VNA architecture with up to 1GHz active load pull bandwidth capability. The system solution provides a flexible load pull test platform that can be used to test the latest high bandwidth and high modulation cellular

standards such as 1024QAM 802.11ax but can also be configured for fast load pull and s-parameter measurements. This opens up the possibility of using this system in all parts of the design cycle, from initial device characterisation, to MMIC or PA design, design verification testing and ultimately to product testing in the factory.

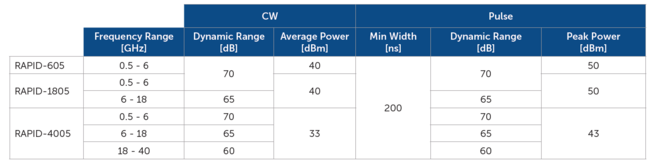

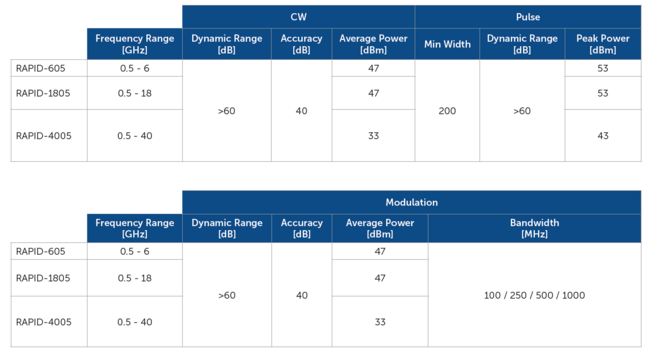

S Parameter Performance Summary

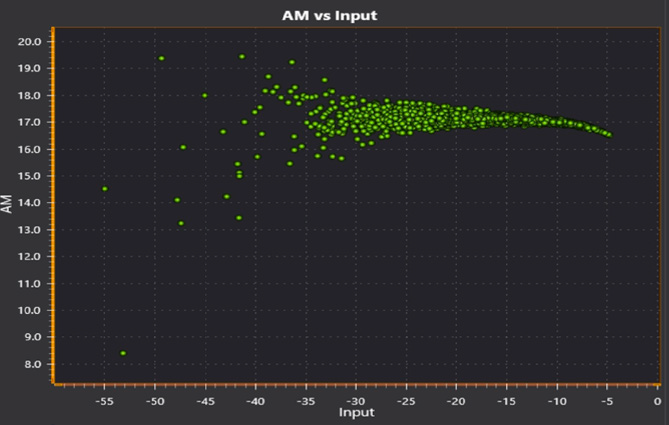

Load Pull Performance Summary

More Product Information

- Focus tunable liquid lens included

- Large working distance range

- Fast focus within milliseconds

- Large image circle

-

High spatial resolution

-

IEEE 1588 PTP

-

Power over Ethernet

-

Defect pixel masking

-

Monochrome (GT5400) and color (GT5400C) models

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Defect pixel masking feature with the Defect Mask Loader tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

The energy industry is primed for a wave of monumental change. The transition to renewable and alternative energy sources, advancements in energy storage, the rise of smart grids, and the electrification of transportation are driving significant changes domestically and globally. These developments mean organizations require new testing protocols, enhanced safety standards, advanced testing equipment, and comprehensive interoperability and cybersecurity assessments. Regulatory changes and technological innovations further complicate testing requirements, demanding scalable and real-world simulation capabilities. When testing facilities must adapt rapidly to support R&D efforts, it’s essential that they ensure the safe, efficient, and sustainable deployment of new energy technologies. All of these factors demand energy laboratories that are future-proofed for innovative solutions.

Food and beverage technology is changing the global food and beverage industry from production to delivery. Consumer and market demand for sustainable and healthy products also means stricter regulations that promote safe consumption, sustainable package production, and effective recycling or disposal. These trends add up to a heightened demand for organizations in the industry to commit to testing protocols that ensure food safety, quality, and compliance with evolving standards. Facilities and manufacturers face challenges such as implementing advanced traceability systems, ensuring the safety and efficacy of new ingredients and packaging materials, and adhering to rigorous environmental regulations. Additionally, the rise of automation and digitalization in food production results in new challenges related to interoperability and cybersecurity. Testing facilities must adapt swiftly to support R&D efforts, ensuring the safe, efficient, and compliant production of innovative food and beverage products in a rapidly changing market landscape.

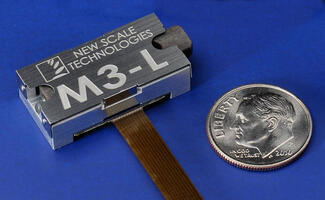

- Small

- Complete, closed-loop system with embedded controls in less than 28 x 13.2 x 7.5 mm

- Precise

- 0.5 µm resolution

- 6 mm of travel

- Simple system integration

- High-level motion commands over standard serial interface (I2C or SPI)

- Flexible system, fast to market

- Rapidly configurable for push or pull motion

- Low voltage / low power use

- 3.3 V input, <500 mW power use

- Holds position when power is off

-

3 Measurement States; Quiescent (OFF-State), Non Quiescent (ON-State), and Pre-State

-

-

The Pre State is a short high voltage state used to activate

the traps in the semiconductor.

-

-

-

Adjustable delay (Δt) between the Pre state and Non Quiescent state down to 0s.

-

Independently adjustable timing settings for the Three-state gate pulser and drain pulser

-

Easy Integration into existing mainframes

Focus Microwaves

Focus Microwaves is a pioneering engineering company, built around the innovations of its founder Dr. Christos Tsironis who developed his first manual tuner in 1973 and is the inventor of most existing electro-mechanical tuner families. The success of Focus is based on the engineering and manufacturing skills of its highly motivated and experienced team of engineers and technicians, who have been trained and encouraged to develop new technologies. In addition, listening to our customers needs and insights helps us discover and develop new and measurement methods on an ongoing basis, relentlessly pushing the limits of what is possible.

From humble beginnings in 1988, Focus has become the main supplier of advanced Load Pull and Noise Tuner Systems. Our mission is to provide effective, reliable and innovative solutions for non-50 Ohm testing (Noise and Load Pull) of RF microwave transistors, thus enabling our customers to compete in the marketplace with better designs and to advance the understanding and knowledge of the field.

Contact Details

Focus Microwaves Inc. Main Head Office

4555 Chem. du Bois-Franc, Saint-Laurent, QC H4S 1A8, Canada

Phone: +1-514-684-4554

Test & Measurement