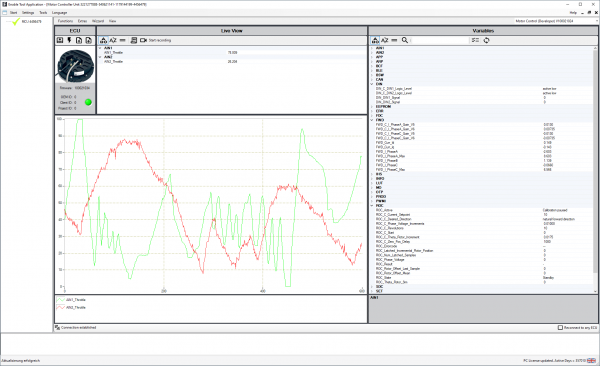

FRIWO - Service Software

-

Firmware update

-

Read error memory

-

Setting of a limited number of parameters per control unit

-

Access to all parameters of an ECU

-

Creation of signed data records for production and aftersales

-

User roles (developer, production, service) for controlling vehicle projects in larger organizations with a dealer network

-

Creation of signed data records for production and aftersales

-

Storage and transmission of data sets

-

Interface to End-of-Line Test

Product information "Service Software"

Enable Tool Application is used for the adjustment and maintenance of our control units in development, production and after sales.

Additional information

- Interface: USB

- System requirements: Microsoft Windows, Dualcore CPU @ 1.8 Ghz, 2GB RAM, 100MB HDD

- Read fault codes: Service and developer

- Change parameters: Developer

- Create datalog: Service and developer

- Create data snapshot: Developer

- Transfer data snapshot on a certain OEM ECU: Service

- Transfer data snapshot all OEM ECUs: Developer

- Variants: 1 User, 1 Year, 1 Project code

- Connectivity: Active online connection

Please download the software Enable Tool Application (ZIP File)

The license key (project code) will be emailed to you within 2 working days at the latest.

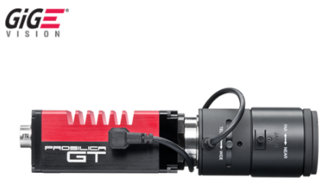

More Product Information

-

Versatile temperature range for extreme environments

-

IEEE 1588 PTP

-

Power over Ethernet

-

P-Iris and DC-Iris lens control

-

Near-Infrared (GT2000NIR) model

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Defect pixel masking feature with the Defect Mask Loader tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

-

Software-driven design allows for field updates for adding new features, capability or modifications due to industry changes

-

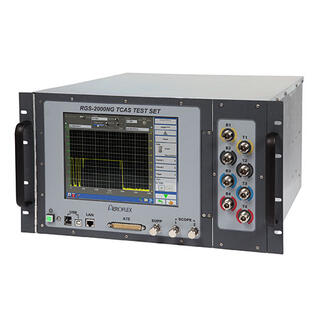

TCAS and ADS-B Target Generator

-

Simulates 32 dynamic/400 static intruders

-

ADS-B squitter encode/decode

-

More test capability than any tester in the market, all packed into one box

-

Pulse and frequency measurement Transponder test option for Modes A, C, S

-

Optional Command set emulation for SDX-2000, ATC-1400A and S-1403DL

-

10.4 inch touch screen LCD display for operator control of all test set capabilities or can be remotely controlled via GPIB or Ethernet

-

Four port antenna simulation

-

Hybrid surveillance

-

Six independent transmitters and two receivers

-

Data parsing for analysis

-

30.0 fps at full resolution

-

Power over Ethernet option

-

Angled-head and board level variants

-

Video-iris lens control

-

Monochrome (G-201B-30fps) and color (G-201C-30fps) models

-

GigE Vision interface with Power over Ethernet option

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

IMX250 CMOS sensor

-

ALVIUM image processing

-

USB3 Vision

-

Various hardware options

-

Monochrome (1800 U-508m) and color (1800 U-508c) models

-

ALVIUM® Technology for on-board image processing

-

USB3 Vision interface for GenICam SFNC features

-

Platform concept that enables the operation of different Alvium camera models with a common software

-

Micro-B USB 3.1 Gen 1 connector with screw locks for industrial applications

-

Precise sensor-to-lens mount alignment

-

Standard M3 mounting holes for top and bottom mounting, standard M2 mounting holes for front mounting

-

Industrial performance for both embedded and machine vision applications

-

Different substrate carriers for wafers up to 200 mm or single dies

-

Probe cards and/or up to eight positioners

-

Probe positioners placed inside vacuum chamber

-

Short and stable probe arms

-

Joystick controller

-

Manual probe positioners with rotary feed-throughs

-

Software control of chuck for fast step-and-repeat testing of the entire wafer

-

Fast step-and-repeat testing of the whole wafer

-

User-centered design minimizes training costs and enhances efficiency

FRIWO

Based on 50 years of experience, FRIWO today has a global presence with modern development centres, production facilities and sales in Europe, Asia and North America. The FRIWO brand stands for innovative strength, security, safety, quality, and efficiency around the world. As proof of this, we are certified according to DIN ISO 9001 (Quality Management), DIN ISO 14001 (Environmental Management), and DIN ISO 13485 (Quality management for medical devices). At the end of the 2020 fiscal year, the company employed over 2,500 people worldwide and generated revenue of 99.4 million euros.

As an international system provider, FRIWO, headquartered in Ostbevern (DE), develops and produces digitally controllable power supply and drive solutions for futureoriented industries such as power tool technology, industrial applications, medical technology or electromobility.

The product portfolio includes technologically leading chargers, battery packs and power supply units as well as intelligent components for electric drive trains. The range of solutions extends from the display, motor control and drive unit to the control software.

Contact Details

FRIWO Gerätebau GmbH Headquarters

Von-Liebig-Straße 11, 48346 Ostbevern, Germany

Phone: +49-25-32-81-0

Fax: +49-25-32-81-112

Email: hello@friwo.com

Embedded