Meatest - M192 Real-Resistance Load

3000W power load based on set of 64 fixed, high-power resistors.

- Maximum load 3 kW and 250 Vrms

- Real resistance function

- Temperature coefficient < 10 ppm/°C

M192 is accurate high power resistance decade for testing of power supplies and batteries up to 3000 W and 250 Vrms. Being a resistance decade rather than an electronic load, resistance function uses real resistance so it can be used with AC power sources as well. See datasheet for typical frequency responses.

Languages: English, German, Czech

Connectivity

All decades' functions can be remotely controlled via RS232 or GPIB interface. This way you can introduce calibration/test stage directly into production line of any resistance based sensor and reduce time required for final quality tests dramatically.

|

Resistance |

15 Ω - 4700 Ω, 64 fixed values ± 0.1% / year |

|---|

More Product Information

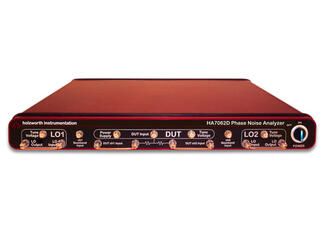

- Automated Absolute and Additive (Residual) Measurements

- Real Time Cross Correlation

- Only analyzer available that allows actual noise floor measurement

- Unparalleled analog performance

- Repeatable data

The HA7162D Real Time Phase Noise Analyzer delivers proven accuracy, high reliability, automation and flexibility. The real time engine covers the full measurement bandwidth with extremely fast measurement speeds to reduce product development time and optimizes ATE manufacturing throughput.

65 ppm AC/DC multifunction calibrator designed specifically for calibration of 3½ and 4½ digit multimeters. 1050 V, 20.5 A, resistance, capacitance and temperature packed inside ultra portable, 11 kg body.

- Compact, light, ideal for onsite calibrations

- 1050 V, 20.5 A, resistance, capacitance, TC, RTD and frequency

- Basic accuracy 60 ppm

- All-round calibrator for 3.5 and 4.5 digit multimeters

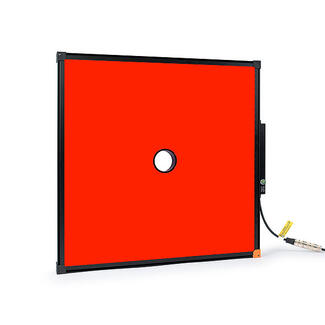

- Large surface lighting with dimensions from 50 mm x 250 mm

- Rectangular, square and elongated design in 50 x 50 mm light field modules freely definable depending on requirements

- Lighting solution individually adapted to the application from the cost-optimized standard portfolio

The new modular LUMIMAX® LED Panel Lights expand the lighting portfolio with larger light areas. Thanks to the modular concept, specific sizes can be realized quickly and without additional development costs. The Panel Lights with integrated controller technology are available in different configurations for incident and backlight applications.

Bank of fixed resistance, capacitance and inductance standards with defined frequency characteristic up to 1 MHz for automated calibration of LCR meters.

- Automated RCL calibration

- Calibration data from 20 Hz to 1 MHz

- No need for pen and paper method

- 4 kHz to 6 GHz and 10 MHz to 6, 18, and 40 GHz power sensors

- -60 dBm to +20 dBm dynamic range

- Pulse, Average, CW and Modulation modes

- True average measurements with essentially no modulation bandwidth limitations

- Real-Time Power Processing™ technology for virtually no gaps in signal acquisition and zero measurement latency

- 100,000 measurements per second

- Synchronized multi-channel measurements

- Suite of advanced measurement and analysis software

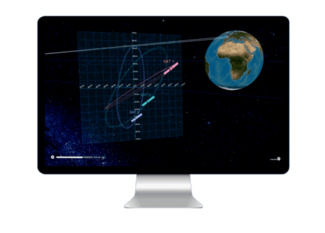

WeTrack® stands as a one-of-a-kind service developed, possessed, and operated by Safran Defense & Space, Inc. (formerly Safran Data Systems, Inc.). Leverage its autonomous network of radio frequency (RF) sensors to attain precise orbital positions with high data update rates, enhancing your decision-making capabilities across all orbit scenarios, thanks to our global coverage. With automated sensors for detection and tracking, stay well-informed 24 hour, every day of the year.

Our patented technology, designed for passive satellite emissions reception, provides comprehensive coverage of all orbits, boasting multiple networks deployed in the United States, Europe, and Asia. WeTrack® grants real-time access to information through a secure web portal.

Resistance decade box designed for RTD and other resistance-based sensors' simulation. 0.01°C accuracy and 0.001°C resolution.

- Real resistors switched by relays

- Custom temperature scales

- No residual resistance

- 0.01°C accuracy

- Six different languages

- Up to 20 GHz bandwidth and 80 GS/s sample rate

- The most advanced oscilloscope user interface

- The industry’s only true hardware 14.1 Gb/s serial trigger

- Low Jitter Measurement Floor and exceptional timebase stability

- Comprehensive set of serial data analysis, debug, validation and compliance tools

- Integrated 50 Ω and 1 MΩ inputs for true connection and probing flexibility

- Integrated standard and custom measurements and math functions for unrivaled analysis capability

- Multi-lane serial data eye, jitter and crosstalk analysis

- Real-time de-embedding, emulation, and equalization

Three phase electric power/energy calibrator for calibration and testing of power meters and power transducers.

- 0.01° phase shift accuracy

- 15 - 1000 Hz output

- Built-in multimeter for transducer calibration

- Floating current outputs for 3-wire power meters

- Voltage from Current function

Meatest

We develop and manufacture electrical calibration instruments for calibration laboratories and testing facilities in electronics, engineering, utility, aeronautics and telecommunications sectors. Designed for automated calibrations our instruments bring effective solutions to customers like NPL, Samsung, Siemens and Volkswagen.

Contact Details

Meatest, spol. s r.o. Headquarters