Schneider Optics - SYLVINE Telecentric Lenses

- Bilateral telecentric design

- Very high resolution down to 2.4µm pixel size

- 2/3" (11 mm) max. sensor size

- C-Mount lens

- 5 magnifications: 0.2x - 1x

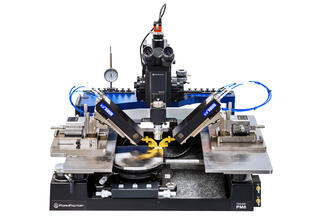

These bilateral telecentric 2/3" C-Mount lenses for 0.2x - 1x magnification are precise instruments for accurate dimensional measurement and high resolution micro inspection. The special telecentric design is the key for easy inspection of holes and tubes. Telecentricity not only on the object but also on the sensor side keeps the image position even with slight defocussing or sensor misalignment.

Discover the compatibility of SYLVINE lenses with top sensor brands

Check out the optimal sensor compatibility for SYLVINE lenses. Our selection includes a variety of compatible sensors from leading manufacturers such as OnSemi, GPixel, Teledyne e2V. Improve your imaging efficiency and accuracy with the ideal lens-sensor combination.

Lens Models

|

Lens |

Magnification |

Numerical Aperture |

Max. Sensor Size |

Mount |

Special Feature |

Datasheet |

|---|---|---|---|---|---|---|

|

0.2x |

0.03 |

(11 mm) 2/3" |

C-Mount |

- |

||

|

0.25x |

0.03 |

(11 mm) 2/3" |

C-Mount |

- |

||

|

0.35x |

0.05 |

(11 mm) 2/3" |

C-Mount |

- |

||

|

0.5x |

0.07 |

(11 mm) 2/3" |

C-Mount |

- |

||

|

1.0x |

0.14 |

(11 mm) 2/3" |

C-Mount |

- |

Didn't find the right fit?

If these models don’t meet your requirements or specifications, explore our complete lens portfolio using our lens selector.

Applications & Markets of the CHAROITE lens

>>>High-Precision Measurement

The lenses are suitable for measurements where the maximum precision is required.

>>>Tube Inspection

The lenses are suitable for high speed, high sensitivity tube inspection applications.

>>>Jewel Inspection

The lenses are suitable for quality control of jewellery to the highest standards.

Environmental Facts of the SYLVINE lenses

Our SYLVINE telecentric lenses are tested to DIN standards to ensure they meet stringent environmental requirements. These tests check the durability of the telecentric lenses, their resistance to temperature changes and their ability to withstand shock tests and sinusoidal vibration. This ensures that the industrial lenses are up to the task in demanding industrial applications such as high-precision measurement or tube inspection, providing consistent performance and reliability over time.

|

Slow Temperature Cycling |

Damp Heat, Cyclic |

Shock Testing |

Sinusoidal Vibration |

|---|---|---|---|

|

-25°C - +70°C 5 cycles a 12h DIN ISO 9022-2-14-03 -1 |

-23°C - +40°C 80% - 95% rel. humidity DIN ISO 9022-2-16-01-1 |

50 g / 11 ms 18 shocks DIN ISO 9022-3-30-06-1 |

2 g 10-500 Hz DIN ISO 9022-3-36-04-1 |

Optical Filters

By protecting the lens, eliminating unwanted wavelengths and enhancing contrast, optical filters improve the image quality of your lens in industrial applications.

>>>You may need an optical filter as well? Click here for more information

More Product Information

Schneider Optics

Large Format, Telecentric and Line Scan Lensing