VTI Instruments - VXI Chassis

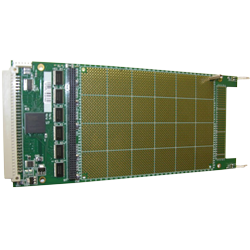

VXI Chassis include 6-slot VXIbus mainframes (CT-100C), 5-slot VXIbus mainframes (CT-310A), and modular 13-slot VXIbus mainframes (CT-400, pictured).

The first VXIbus specification was introduced to the test and measurement community in 1987 and was initially developed to provide a card-based instrumentation platform for applications that required high density and high performance. The platform continues to thrive today by leveraging off the original specifications which define the necessary physical (real estate/cooling) and electrical standards for demanding applications and has established itself as the ‘time-tested bus you can trust’ for requirements that must be supported in excess of ten-fifteen years.

The VXIbus was well conceived by leading test and measurement companies to solve the most demanding test applications. The VXIbus is established. It has a 25+ year history of success and continues to be the leading modular instrument test platform. The VXIbus is time tested, providing systems designers with security in the knowledge that their test platform will outlive the device being tested. The VXIbus is thriving and has proven that it has the flexibility to evolve with the development of new technologies.

|

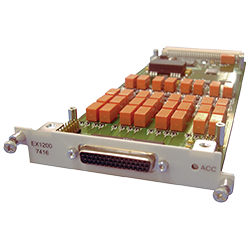

CT-100C |

6-slot VXIbus mainframe |

|---|---|

|

CT-310A |

5-slot VXIbus Mainframe (for Rack and Portable Use) |

|

CT-400 |

Modular 13-slot VXIbus Mainframe |

More Product Information

VTI Instruments

Data Acquisition, Signal Conditioning, Switching, Modular Instruments & VXI Mainframes