-

Pre-Engineered Scalability Enables Customized Emitting Lengths in 2″ Increments to 20″

-

Intense, Diffuse Lighting with 226 kLux at Emitting Surface

-

Multiple Available Wavelengths, Including Visible Monochromatics, Infrared, and White

-

Available Washdown Option for Difficult Environments

-

Can be Applied in Backlighting or Diffuse Front Lighting Geometries

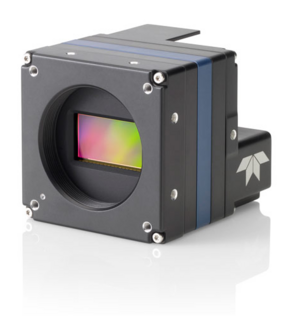

Advanced Illumination - RL2115 Compact Aimed Dark Field

- The RL2115 is characterized as a Compact Aimed Dark Field ring light.

- Precisely aimed LEDs provide a specific and repeatable light pattern on the imaging plane.

- There are a wide range of wavelengths available from UV to IR.

General Specs

|

Electrical Specifications |

Color |

24V Current |

All Other Controls |

|---|---|---|---|

|

625, 660, 880 |

0.09A |

0.067A Max |

|

|

395, 470, 520, WHI |

0.06A |

0.045A Max |

|

|

Normal Operating Temperature |

0 - 60°C |

||

|

Weight |

57.2g (2.02oz) | ||

|

Standard Cable Information |

2 m long -0/+150 mm (80" -0/+6") - 105°C rated PVC jacket, foil shield with drain. |

||

|

Photobiological Risk Factor |

Exempt Applicable Wavelengths: 880 Group 1 (Low-Risk) Applicable Wavelengths: 470, 520, 625, 660, WHI Group 2 (Moderate-Risk) Applicable Wavelengths: 395 |

||

|

Compliance |

CE, RoHS, IEC 62471 |

||

|

IP Rating |

Not Rated |

||

|

Lumen Maintenance |

L70 = 50,000 Hours |

||

Mechanical Specs

Optical Specs

Electrical Specs

Control Specs

Part Number Key

More Product Information

Advanced Illumination

Machine Vision Lighting Solutions