Schneider Optics - SAPPHIRE Line Scan Lenses

- Extremely high resolution down to 3.5µm pixel size

- Image circle: 62.5 mm - 82 mm

- Optimized for specific magnifications

- 11 magnifications available: 0.07x - 2.0x

- Version with Beamsplitter available

- Best azimuth marking

- V70-Mount for easy installation

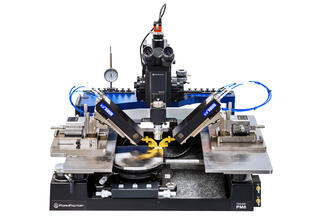

SAPPHIRE lenses set a new standard in vision technology. Designed specifically for high-resolution applications, they offer an impressive resolution of up to 3.5µ pixel size. These lenses are the perfect solution for those who require the highest image quality and precision. SAPPHIRE lenses are highly adaptable. The high performance lenses are optimized for 16k / 3.5µm and 12k / 5µm (SAPPHIRE XL: 16k / 5µm) line sensors. With an image circle of 62.5 mm to 82 mm, they can be used with both line sensors and area sensors up to 82 mm diagonal. This means maximum flexibility for your applications. We understand that each application has different requirements. That's why our SAPPHIRE lenses offer 11 different magnification options from 0.07x to 2.0x. So you can choose the perfect magnification for your specific application and get the best possible results.

For even more versatility, we offer a beamsplitter version. In addition, the V70 mount makes it easy to mount and rotate the objective into the best azimuth. Marking the best azimuth ensures that you always have the best alignment for your application. Our Sapphire lenses are the ultimate choice for demanding applications that require the highest resolution, flexibility and precision. With their robust housings and numerous customization options, they are the perfect solution for your technical requirements.

Discover the compatibility of SAPPHIRE lenses with top sensor brands

Check out the optimal sensor compatibility for SAPPHIRE lenses. Our selection includes a variety of compatible sensors from leading manufacturers such as OnSemi, GPixel, ams. Improve your imaging efficiency and accuracy with the ideal lens-sensor combination.

Lens Models

|

Lens |

Magnification |

Numerical Aperture |

Max. Sensor Size |

Mount |

Special Feature |

Datasheet |

|---|---|---|---|---|---|---|

|

0.07x |

0.007 |

62.5 mm |

V70-Mount |

- |

||

|

0.23x |

0.02 |

62.5 mm |

V70-Mount |

- |

||

|

0.29x |

0.03 |

62.5 mm |

V70-Mount |

- |

||

|

0.35x |

0.04 |

62.5 mm |

V70-Mount |

- |

||

|

0.5x |

0.05 |

62.5 mm |

V70-Mount |

- |

||

|

0.7x |

0.06 |

62.5 mm |

V70-Mount |

- |

||

|

0.875x |

0.08 |

62.5 mm |

V70-Mount |

- |

||

|

1.143x |

0.09 |

62.5 mm |

V70-Mount |

- |

||

|

1.43x |

0.09 |

82 mm |

V70-Mount |

- |

||

|

1.75x |

0.10 |

62.5 mm |

V70-Mount |

- |

||

|

1.75x |

0.10 |

62.5 mm |

V70-Mount |

Beamsplitter |

||

|

2.0x |

0.10 |

82 mm |

V70-Mount |

- |

Didn't find the right fit?

If these models don’t meet your requirements or specifications, explore our complete lens portfolio using our lens selector.

Applications & Markets of the SAPPHIRE lenses

Automated (FPD) inspections can detect and correct defects in displays at an early stage.

PCB inspection is the checking of printed circuit boards for faults and deviations to ensure that they meet the requirements.

>>>Automated Optical Inspection

Automated optical inspection (AOI) uses cameras and software to inspect and analyze components for defects in a manufacturing process.

The camera is placed along a production line that quickly scans along the movement of the product.

Environmental Facts of the SAPPHIRE lenses

Our SAPPHIRE line scan lenses are tested to DIN standards to ensure they meet stringent environmental requirements. These tests check the durability of the line scan lenses, their resistance to temperature changes and their ability to withstand shock tests and sinusoidal vibration. This ensures that the industrial lenses are up to the task in demanding industrial applications such as display inspection or pcb inspection, providing consistent performance and reliability over time.

|

Slow Temperature Cycling |

Damp Heat, Cyclic |

Shock Testing |

Sinusoidal Vibration |

|---|---|---|---|

|

-25°C - +70°C 5 cycles a 12h DIN ISO 9022-2-14-03 -1 |

-23°C - +40°C 80% - 95% rel. humidity DIN ISO 9022-2-16-01-1 |

50 g / 11 ms 18 shocks DIN ISO 9022-3-30-06-1 |

2 g 10-500 Hz DIN ISO 9022-3-36-04-1 |

Optical Filters

By protecting the lens, eliminating unwanted wavelengths and enhancing contrast, optical filters improve the image quality of your lens in industrial applications.

>>>You may need an optical filter as well? Click here for more information

More Product Information

Schneider Optics

Large Format, Telecentric and Line Scan Lensing