Trenton Systems - Blade Servers

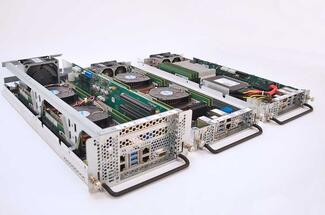

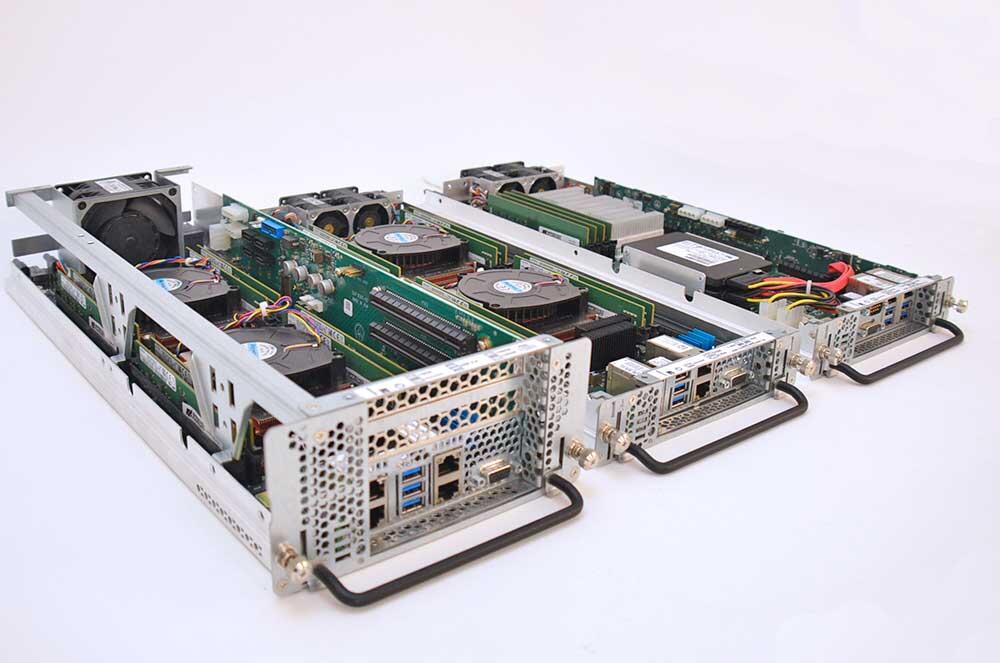

Secure, compact, scalable fixed, front-removable, or rear-removable blade servers made right here in the USA that maximize performance and adaptability for evolving applications

- Size - Up to four server blades within a single rugged enclosure help efficiently utilize rack space.

- Weight - Compact system design reduces overall weight of rack server infrastructure.

- Power - Shared resources optimize hardware usage and limit power requirements.

- Cost - Modularity and increased footprint lower hardware and maintenance costs.

Technical Highlights

- 1U - 2U Form Factors

- Up to 2x PCIe 5.0 slots

- Up to 24x DIMM slots

- Internal/removable SSDs

- Intel Xeon®, Core® CPUs

Compute density. Redefined.

Greatly consolidate workloads while reducing footprint and hardware costs with multiple single- or dual-CPU blades in one chassis. Each processor can run a separate application.

Configurable and future proof hardware.

Hot-swappable blades let you easily incorporate the latest technologies and scale your server to meet the demands of evolving workloads within diverse data environments.

More Product Information

Trenton Systems

Founded in 1989, Trenton Systems provides the defense, government, industrial, and commercial markets with advanced, TAA-compliant high-performance computing solutions designed in consultation with customers. Equipped with the latest processing, AI/ML/DL, networking, security, and storage technologies, our solutions are designed in collaboration with our global partnership ecosystem.