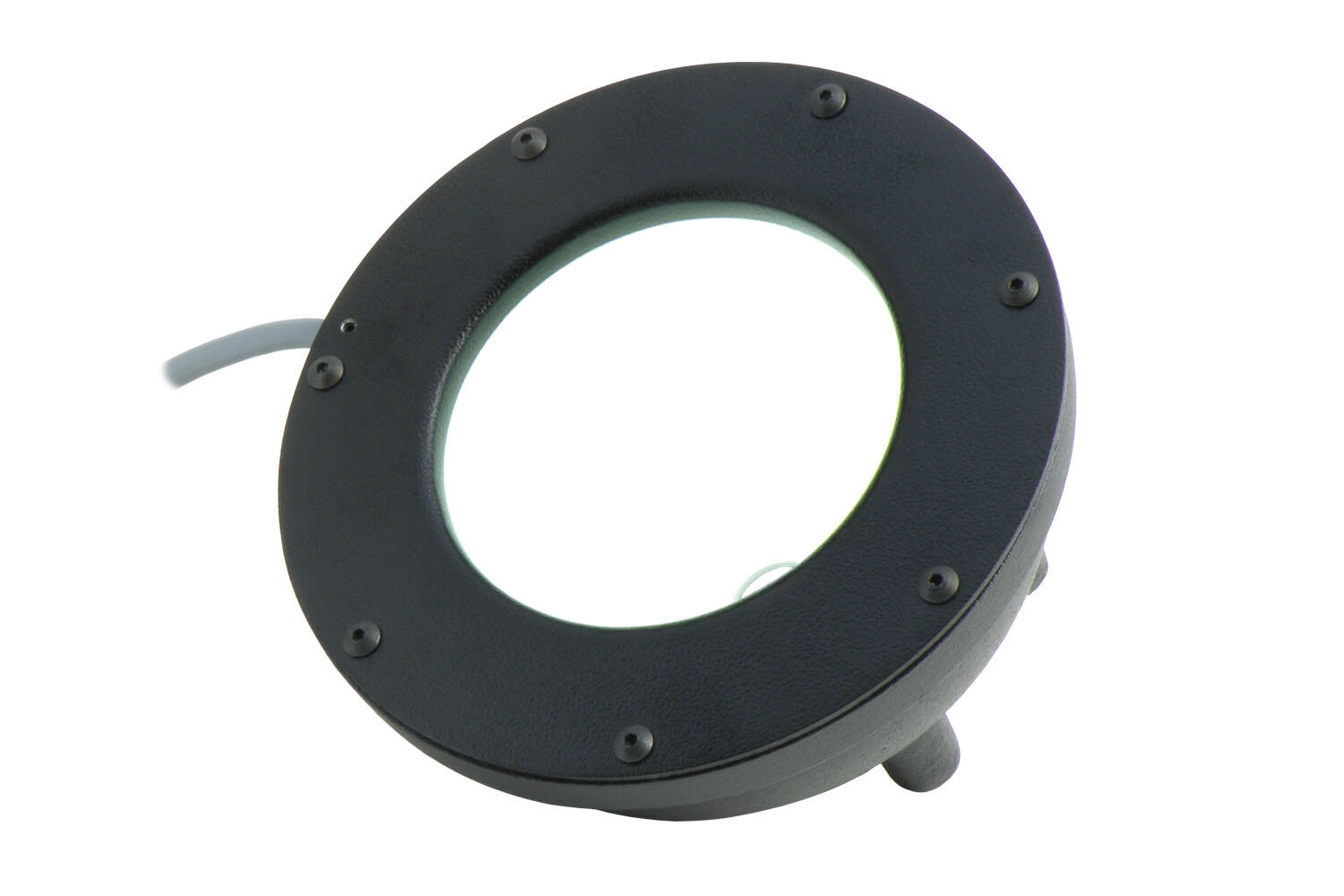

Advanced Illumination - DL194 Small Dome Light

- The Small Dome Light is available in a wide range of wavelengths including a 3 channel, RGB configuration.

- Rugged, cast aluminum housing has an outer diameter of 5.25” (133.3mm) and an inner, working diameter of 3.1” (78.7mm).

- Provides up to 79kLux at a 1” (25mm) standoff.

General Specs

|

Electrical Specifications |

Color |

24V Current |

All Other Controls |

|---|---|---|---|

|

RGB |

0.36A |

TBD |

|

|

WHI, 455 |

0.36A |

0.80A Max |

|

|

470, 505, 530, 590 |

0.36A |

0.85A Max |

|

|

625, 660, 730, 850, 940 |

0.36A |

0.62A Max |

|

|

Normal Operating Temperature |

0 - 60°C |

||

|

Weight |

439.9g (15.52) | ||

|

Standard Cable Information |

2 m long -0/+150 mm (80" -0/+6") - 105°C rated PVC jacket, foil shield with drain. |

||

|

Photobiological Risk Factor |

Exempt Applicable Wavelengths: 580, 940 Group 1 (Low-Risk) Applicable Wavelengths: 505, 530, 590, 625, 660, 730, WHI, RGB Group 2 (Moderate-Risk) Applicable Wavelengths: 455, 470 |

||

|

Compliance |

CE, RoHS, IEC 62471 |

||

|

IP Rating |

Not Rated |

||

|

Lumen Maintenance |

L70 = 50,000 Hours |

||

Mechanical Specs

Optical Specs

Electrical Specs

Control Specs

Part Number Key

More Product Information

Advanced Illumination

Machine Vision Lighting Solutions