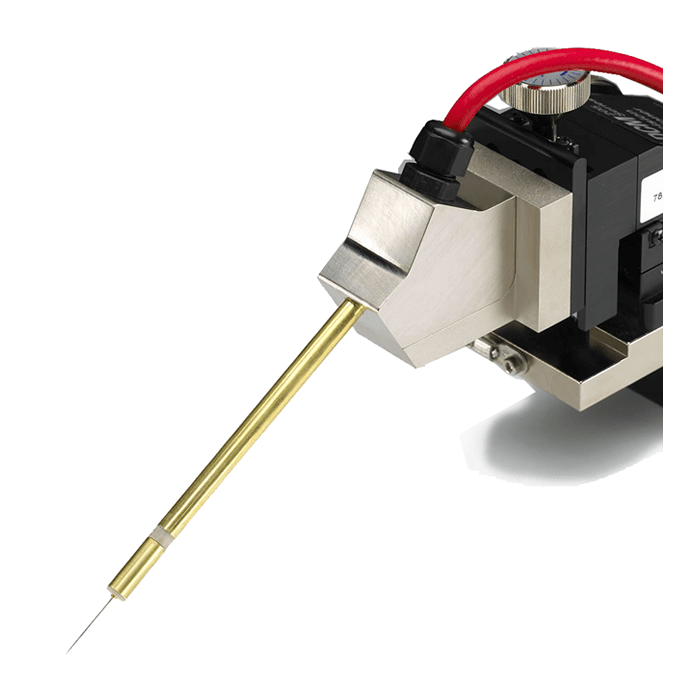

FormFactor - Cascade High Voltage Probe - Accurate and precise measurement of device parameters up to 10,000 V

- Coaxial and triaxial measurements up to 10,000 V

- High-quality construction with low-noise electrical performance

- Replaceable probe tips in a variety of tip sizes

- Temperature range of of -60°C to 300°C

- Triaxial measurement ensures a much better understanding of device leakage in the off state

- Highly reliable, stable and repeatable measurements

- Integrally designed as part of a complete measurement solution

To ensure precision measurements of today’s high-voltage devices, FormFactor’s High-Voltage Probes (HVP) provide increased isolation resistance and dielectric strength by incorporating advanced internal isolation materials, as well as custom cabling and connectors.

When used with a , the HVP assures low-noise electrical performance and full triaxial capability at high voltage without any breakdowns.

More Product Information

MP1900A series is an 8-slot modular, high-performance BERT supporting all-in-one Physical layer measurements of both high-speed network interfaces as NRZ and PAM4, and PCI Express/USB, bus interfaces

LUMIMAX® LED area lights are for versatile use in all areas of Machine Vision for incident or backlight tasks. Their designs allow for any arrangement around the object to be inspected.

LED Area lights in the LG series are based on our LightGuide technology. State-of-the-art LightGuide technology guarantees the maximum degree of homogeneity and irradiance intensity over the entire light field. Variants with additional collimation accessories improve image contrast and minimise the glare effect at manual workstations. See in our Video - Principle Collimated Backlight Video the detailed principle of the collimated backlight.

The area lights of the LGCB series with a camera hole can also be used as a flat dome within a reflected light application and thus create a full-area, shadow-free illumination of the test object.

With the lightings of the BASIC series even price-sensititve applications can be reliably implemented.The focus here is on the realization of essential functions at high quality. A smart and lightweight design ease the integration in confined or moving machine vision systems.

The LEGION 400 tackles the new challenges of the space industry, offering enhanced connectivity, faster delivery, improved value, and unrivaled flexibility.

This antenna system is designed to meet the demands of Earth Observation satellite tracking and the high-volume needs of Communication Satellite Constellations.

What sets the LEGION 400 apart is its patented tri-band S/X/Ka concentric feed paired with a sleek and ultra-precise pedestal. It’s equipped to support LEOP & Launch Vehicles with its cutting-edge S-band Single Channel Monopulse auto track feed.

Resistance decade box with 1 Ω - 1.2 MΩ range, high accuracy and temperature stability. Best resolution 10 μΩ, RTD temperature sensor simulation feature.

- Real resistors switched by relays

- Custom units and time sequences

- No residual resistance

- 20 ppm accuracy

- Six different languages

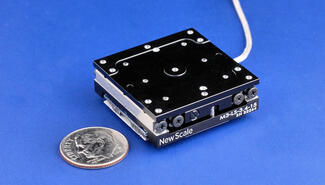

- All-in-one microstage - no separate controller

- Direct high-level command interface (I2C or SPI)

- USB adapter enables direct connection to PC

- Small: < 32x32x11 mm including controller

- Absolute encoding: high repeatability, no homing

- Low power: 6 VDC, ~5 W (only when moving)

- For integration into battery powered devices

- Long stroke: 15 mm

- High force: 1 N (~100g load vertical, ~200g horizontal)

- High stiffness with crossed roller bearing design

- Boost performance by up to 3x over its precursor thanks to an Intel x6000 series embedded processor

- Capture high-resolution images at high speed through a choice of CMOS sensors from two to 16 Megapixels

- Deploy in dirty, humid, or harsh industrial environments by way of a compact IP67-rated design

- Communicate actions and results to other automation and enterprise equipment via real-time digital I/Os, and Ethernet (TCP/IP, CC-Link IE Field Basic, EtherNet/IP™2, Modbus® , PROFINET® , and native robot interfaces)

- Handle Human-Machine Interface (HMI) function by way of VGA and USB connectivity

- Simplify vision setup and upkeep via integrated lens focusing and illumination intensity control

- Synchronize to the manufacturing line through the support for incremental rotary encoders

- Solve machine vision applications efficiently with Aurora Design Assistant by constructing flowcharts instead of writing program code

- Maintain control and independence through the ability to code custom flowchart steps

- Tackle machine vision applications with utmost confidence using field-proven tools for analyzing, locating, classifying, measuring, reading, and verifying

- Leverage deep learning for visual inspection through image classification and segmentation tools

-

High SNR mode (up to 24 dB better signal-to-noise ratio)

-

Low-noise binning mode

-

Shading correction

-

Defect pixel correction

-

Area of interest (AOI), separate AOI for auto features

-

Binning

-

Decimation

-

Auto gain (manual gain control: 0 to 24.4 dB)

-

Auto exposure (39 µs to 67 s)

-

Auto white balance

-

Look-up table (LUT)

-

Hue, saturation

-

Color correction

-

Local color anti-aliasing

-

Reverse X/Y

-

Deferred image transport

-

Trigger programmable, level, single, bulk, programmable delay

-

Sequence mode (changes the camera settings on the fly)

-

SIS (secure image signature, time stamp for trigger, frame count etc.)

-

Storable user sets

-

Camera and IEEE 1394b cable (other configurations on request)

-

Versatile temperature range for extreme environments

-

IEEE 1588 PTP

-

Power over Ethernet

-

EF lens control

-

Monochrome (GT1930L) and color (GT1930LC) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

The Sony IMX174 Exmor is a high sensitivity CMOS sensor

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjustable (PA) EF Lens Mount for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

- Enables wafer probing up to 100 A pulsed and 10A DC

- Innovative multi-fingertip design provides even distribution of current

- Supports up to 500 V

- Replaceable Tungsten probe tips

- Temperature range of -60°C to 300°C

- Minimal contact resistance at the pad-tip junction to reduce heating during measurements, with fewer probe marks

- Prevents against thermal runaway

- Measure devices on wafer at higher currents than ever before

- Small scrub minimizes damage to aluminum pad

- Small footprint – tip fits on a 1 mm pad

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.