FormFactor - HPD JDry-500 - Cryogen-free Dilution Refrigerator

-

Low running costs, less vibration, less noise, reduced maintenance

-

Large convenient experimental access: Up to 12 line-of-sight ISO100 ports located on perimeter of plates

-

CMN calibrated thermometry on MC plate

-

Operation via touch panel controller: Remote operation via ethernet interface

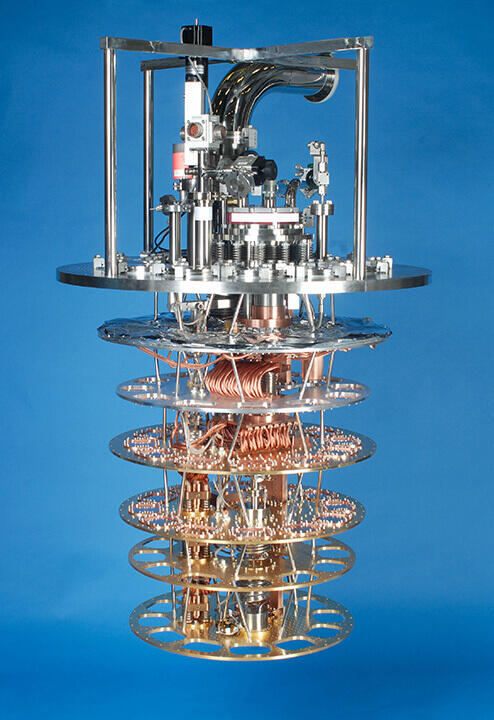

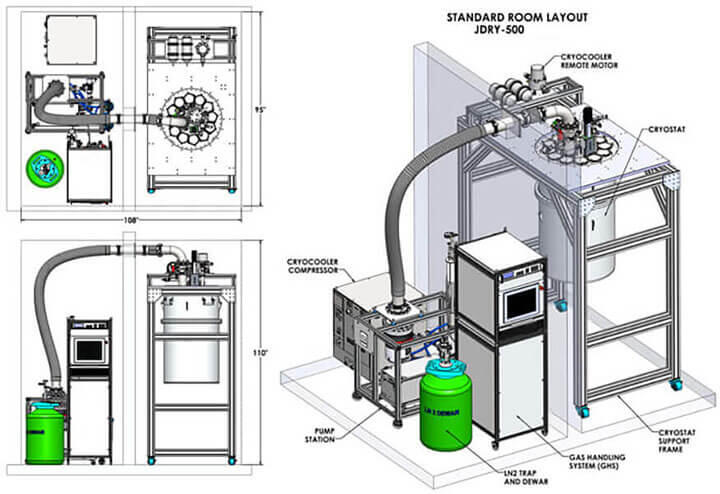

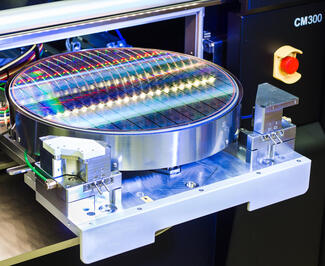

FormFactor’s JDry cryogen-free dilution refrigerators enable easy and cost-effective cooling to temperatures below 10 mK. The JDry models have been optimized for quantum computing applications and can accommodate up to 270 semirigid cables. General-purpose configurations and astronomy/detector cooling are also provided.

The JDry cryogen-free dilution refrigerator series includes multiple standard models. All are available with easy push-button cooling using the robust and fully-automated NI LabVIEW™-based “JACoB” gas-handling system (GHS).

The JDry-500 model is fitted with a cold-plate of 508 mm (20″) diameter, and provides a cooling power of more than 450 µW at 100 mK.

More Product Information

-

Re-configurable for DC, RF, mmW, FA, WLR and more

-

Thermal range: -60˚C to 300˚C available

-

Upgrade path to meet your future needs

-

Stable and repeatable measurements over a wide thermal range

-

Moisture-free, light-tight and EMI-shielded test environment with MicroChamber® technology

-

Advanced EMI-shielding with PureLine with AttoGuard technologies

-

Best solution for low-noise and 1/f measurements

-

Minimize AC and spectral noise

-

Minimizes settling times for efficient measurements, without compromising accuracy over full thermal range

-

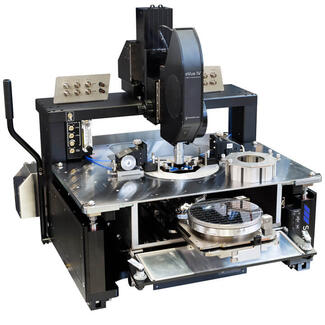

Locking roll-out stage

-

Innovative microscope remote control

-

Intuitive ergonomic stage controls

-

Quick, safe, and comfortable wafer access

-

Easy on-wafer navigation

-

Fast setup and test data gathering

-

Dedicated Velox version for manual probe stations

-

AugmentedAlign tool with on screen markers for improved RF measurement accuracy

-

Different substrate carriers for wafers up to 200 mm or single dies

-

Probe cards and/or up to eight positioners

-

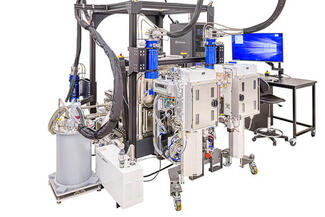

Ice- and condensation-free probing down to 77 K (liquid nitrogen) or below 20 K (liquid helium)

-

Probe positioners placed inside vacuum chamber

-

Joystick controller

-

Manual probe positioners with rotary feed-throughs

-

User-centered design minimizes training costs and enhances efficiency

-

Comprehensive alignment functions – from simple wafer alignment and mapping to automated alignment and test of multiple singulated chips, like IR – Focal Plane Arrays

-

Probe loss is 3 dB typical between 140 and 200 GHz, S11/S22 15 dB typical

-

Reduced unwanted couplings and transmission modes

-

Able to shrink pad geometries to 25 x 35 µm (best case)

-

Typical contact resistance < 0.05 Ω on Al, < 0.02 Ω on Au

-

WR15, WR12, WR10, WR8, WR6, WR4, WR3, and WR2 bands available.

-

Wafer temp verified <4.5 K (with 44 RF probes in contact)

-

Magnetic field suppression to <200 nT

-

Easy exchange of customizable probe cards

-

Configurable for 150 mm, 200 mm and 300 mm wafers

-

Options for fully automated wafer load or manual

-

Complete software suite for manual, semi-auto, or fully automated probing

-

25 wafer cassette capacity for fully automated testing

-

~15 minute cooldown time per wafer

-

Advanced MicroVac chuck surface for minimum contact resistance between wafer and chuck

-

Safety-rated interlock system for high-power testing (meets EN 60947-5-1, EN 60204-1)

-

Supports fully automated testing up to 10kV by eliminating arcing point

-

Full wafer access via locking roll-out stage

-

On-wafer power device characterization up to 10,000 V DC / 600 A

-

Coaxial, triaxial, and pin jack feed-troughs available

-

Convenient instrument connection kits

-

Load/unload wafer to hot/cold chuck (-60° C to +300° C)

-

Up to 15% faster transition times than other systems in the market

-

Revolutionary technology advancement for wafer and die-level photonics probing

-

Highest accuracy in test results

-

New innovative combination of hardware and software features to align and optimize fibers/arrays in a wafer-level trench

-

Minimized coupling losses with minimal trench dimensions

-

Industry standard for vertical coupling to wafer-level grating couplers

-

Positioning hardware is precisely calibrated to the probe station and ready to perform die-to-die optical optimizations in minutes

-

Dark, shielded and frost-free

-

-40°C to +125°C

-

Leveraging considerable expertise through an innovative engineering team

-

Pioneering set of automated functions that perform critical calibrations of the optical positioning system to the probe station

-

Exclusive FormFactor-developed automated test methodology

-

Automates manual tasks by integrating probe station machine vision capability with optical positioning and test equipment

-

FormFactor-developed graphical user interface to manually control the optical positioning system

-

Configurable between single fibers, fiber arrays and edge coupling holders

-

Application flexibility: Coax, Triax, RF/mmW, High Power, Double Sided

-

Temperatures range from -60°C to +300°C

-

Up to 25% lower air consumption (CDA) than other systems on the market with no compromise in transition times

-

Low Thermal Resistance Technology

-

MultiSense with multiple temperature sensors

-

Isolated from ground

-

Includes a jack for grounding and biasing

-

Advanced wafer vacuum system for warped/partial thin wafers

-

Provides uniform vacuum across the entire wafer surface

-

Advanced shielding technology

-

Cryogen-free: cooling with two-stage pulse tube refrigerator (PTR)

-

Low vibration

-

Mechanical heat switch

-

Internal charcoal sorption pump

-

DC, AC and RF/microwave device characterization, 1/f, WLR, FA and design debug

-

Full thermal range of -60°C to +300°C

-

Reliable and repeatable contact

-

Moisture-free, light-tight and EMI-shielded test environment with MicroChamber® technology

-

Enables full access to the chuck and the auxiliary sites

-

Intuitive, and precise movement of chuck in X, Y, and Z-direction

-

High thermal stability components

-

On-axis probe-to-pad alignment

-

Flexibility from hot only to full thermal range of -60°C to +300°C

-

Thermally induced drift can be automatically re-aligned for 30 μm pads in a temperature range from -40°C to 150°C (the effective temperature range depends on pad size, probe card holder and probe card)

-

3 performance level configurations (fully-shielded / shielded / open)

-

Test automation out-of-cassette for higher test cell efficiency for over-night/over-weekend operation

-

User-centered design minimizes training costs and enhances efficiency

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.

Contact Details

FormFactor, Inc. Corporate Headquarters

7005 Southfront Road, Livermore, CA 94551, USA

Phone: 925-290-4000

Test & Measurement