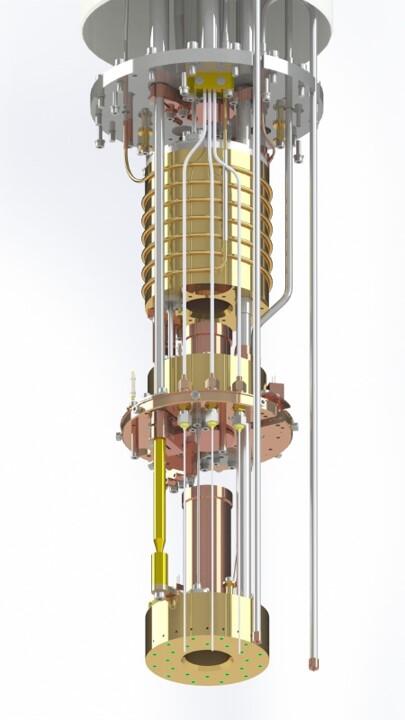

FormFactor - HPD Model HE-3-TLSUHV-STM - Wet Helium-3 Cryostat

-

Long holding time: 80 hours with 10 STP liter He-3 gas

-

Stable He-3 pot temperature: Separate sippers for 1K pot and the charcoal sorb cooling line

-

Sample can be loaded or removed when the cryostat is cold

-

Low noise, low vibration

-

Multiple operation modes: He-3 cryostat can be operated without pumping the 1K pot (referred to as 4K operation mode)

The Model HE-3-TLSLUHV-STM is a top-loading Helium-3 cryostat with sample in ultra-high vacuum (UHV) space for scanning tunneling microscopy (STM) with atomic resolutions. The sample can be loaded through the 1.0” diameter central access when the cryostat is cold. With its standardized unique design, this He-3 cryostat generates next to zero acoustic noise and mechanical vibration. The Model HE-3-TLSUHV-STM He-3 insert is designed to be compatible with all kinds of superconducting magnets, such as solenoid, vector magnets, and more.

This He-3 insert includes the following components:

- Central access with gate valve on top

- Charcoal sorption pump with heater and thermometer

- 1 K pot with heater and thermometer

- He-3 pot with heater and thermometer

- Permanently stored He-3 gas

- UHV compatible IVC can

- Mechanical heat switches

- Operation test

More Product Information

-

Teledyne e2v Sapphire CMOS sensor

-

Switchable shutter modes

-

Power over Ethernet

-

60 fps at full resolution

-

Monochrome (G-192B) and color (G-192C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Defect pixel masking feature with the Defect Mask Loader tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

-

Select between B 270 ASG protection glass and filter types: Jenofilt 217 IR cut filter, Hoya C-5000 IR cut filter, RG715 IR pass filter, or RG830 IR pass filter

- Available in 250 MHz and 350 MHz models

- 2, 4 and 8 channel modes

- 16-bit vertical resolution

- Max Sampling rate of 1.2 GS/s

- Max sinewave frequency of 250 MHz and 350 MHz respectively

-

Versatile temperature range for extreme environments

-

IEEE 1588 PTP

-

Power over Ethernet

-

P-Iris and DC-Iris lens control

-

Monochrome (GT2750) and color (GT2750C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Defect pixel column masking feature with the Load Defect Tables tool that allows you to manage a user defined defective pixel list to match your application and optimize the life cycle of the camera.

PureLine 3 Technology

- Provides an effectively noise free environment around the device under test (DUT)

- First automated probe station to achieve -190dB spectral noise*

- Up to 32x lower noise (1kHz), for improved device characterization and modelling at the 7/5/2 nm technology nodes targeted for 5G and beyond applications

- Eliminates over 97% of the environmental noise experienced in previous probe systems

- Extensive collection of FormFactor patents, electrical design knowledge, and measurement system IP

Plug In and Go

- World’s first probe station with integrated TestCell Power Management (a TestCell is a connected set of equipment, including test software, instruments, probe station, thermal system, and related measurement accessories such as cables and on-wafer probes)

- Eliminates all ground-loop induced TestCell noise

- Low field emissions

- Provides fully managed and filtered AC power to the entire system, prober and instruments

See "Specifications & Details" tab for more key features

- The DL225 series of square coaxial lights features a modular heat sink and circuit design for enhanced performance, product availability and lead time.

- These coaxial lights are available in a wide variety of wavelengths from UV to IR.

- They provide intensities from 18kLux for the DL225-025 to approximately 50kLux for the larger models.

- Frequency range of 9 kHz to 3.6 GHz/6 GHz/26.5 GHz/44.5 GHz; 44.5 GHz max. built-in preamp option

- Best close-in phase noise performance in middle range signal analyzer/spectrum analyzer:

- –123 dBc/Hz (at 1 GHz center frequency, 10 kHz offset frequency with all frequency models)

- –138 dBc/Hz (at 1 GHz center frequency, 10 kHz offset frequency with 3.6 GHz and 6 GHz models, meas.)

- –140 dBc/Hz (at 150 MHz center frequency, 10 kHz offset frequency with 3.6 GHz and 6 GHz models, meas.)

- 31.25 MHz analysis bandwidth (standard); 125 MHz max. (option)

- All-in-one solution with built-in signal generator option supports TRx tests (with 3.6 GHz and 6 GHz models)

- Measurement applications (options): Phase Noise Measurement, Noise Figure Measurement, Vector and Analog Modulation Analysis, BER Measurement, Pulse Radar Measurement Function

-

Monochrome (G-234B) and color (G-234C) models

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

IEEE 1588 Precision Time Protocol allows for easy synchronization of multiple cameras and devices on network

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Comprehensive I/O functionality for simplified system integration

-

Popular C-Mount lens mount

-

Easy camera mounting via standard M3 threads on top and bottom of housing or optional tripod adapter

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Select between B 270 ASG protection glass and filter types: Jenofilt 217 IR cut filter, Hoya C-5000 IR cut filter, RG715 IR pass filter, or RG830 IR pass filter

-

Superior field confinement reduces unwanted couplings to nearby devices and transmission modes

-

Superior measurement accuracy and repeatability

-

Small scrub minimizes damage to aluminum pad

-

Typical contact resistance < 0. 05 Ω on Al, <0.02Ω on Au

-

Save valuable wafer space and reduce pad parasitics by being able to shrink pad geometries to 25 x 35 µ m (best case)

-

Type APS-H CMOS sensor

-

IEEE 1588 PTP

-

Power over Ethernet

-

4.59 fps at full resolution

-

Extended near-infrared (GT5120NIR) model

-

GigE Vision interface with Power over Ethernet

-

Screw mount RJ45 Ethernet connector for secure operation in industrial environments

-

Supports cable lengths up to 100 meters (CAT-6 recommended)

-

Trigger over Ethernet Action Commands allow for a single cable solution to reduce system costs

-

Comprehensive I/O functionality for simplified system integration

-

Planarity adjusted (PA) EF Lens Mount (option -18) for electronic control of aperture and autofocus

-

Easy camera mounting via standard M3 threads at all sides and 1/4-20 tripod mounting hole

-

Easy software integration with Allied Vision's Vimba Suite and compatibility to the most popular third party image-processing libraries.

-

Enhanced Defect Pixel Correction feature with a new Defective Pixel List Manager tool that allows you to load different user defined defective pixel lists to match your application and optimize the life cycle of the camera

FormFactor, Inc.

FormFactor, Inc. (NASDAQ:FORM) is a leading provider of essential test and measurement technologies along the full IC life cycle – from characterization, modeling, reliability, and design de-bug, to qualification and production test.

We constantly strive to help our customers solve the advanced test and measurement challenges of the broader semiconductor industry. Our focus on customer partnership, innovation, agility and operational excellence allows us to earn sustainable business every day.

Contact Details

FormFactor, Inc. Corporate Headquarters

7005 Southfront Road, Livermore, CA 94551, USA

Phone: 925-290-4000

Test & Measurement